Ketoxime ester photoinitiator

A technology of photoinitiators and esters, applied in the field of ketoxime ester photoinitiators, can solve the problems of poor thermal stability and poor application performance, and achieve the effect of good application performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

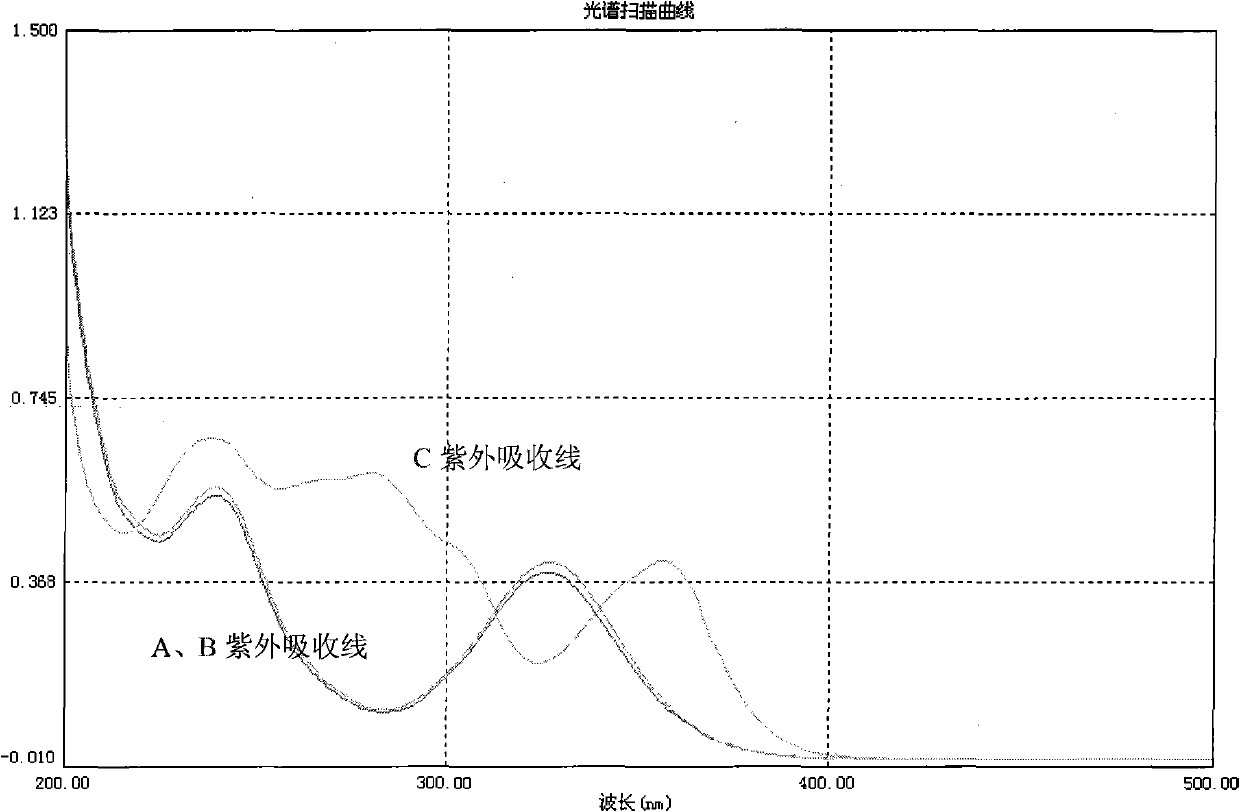

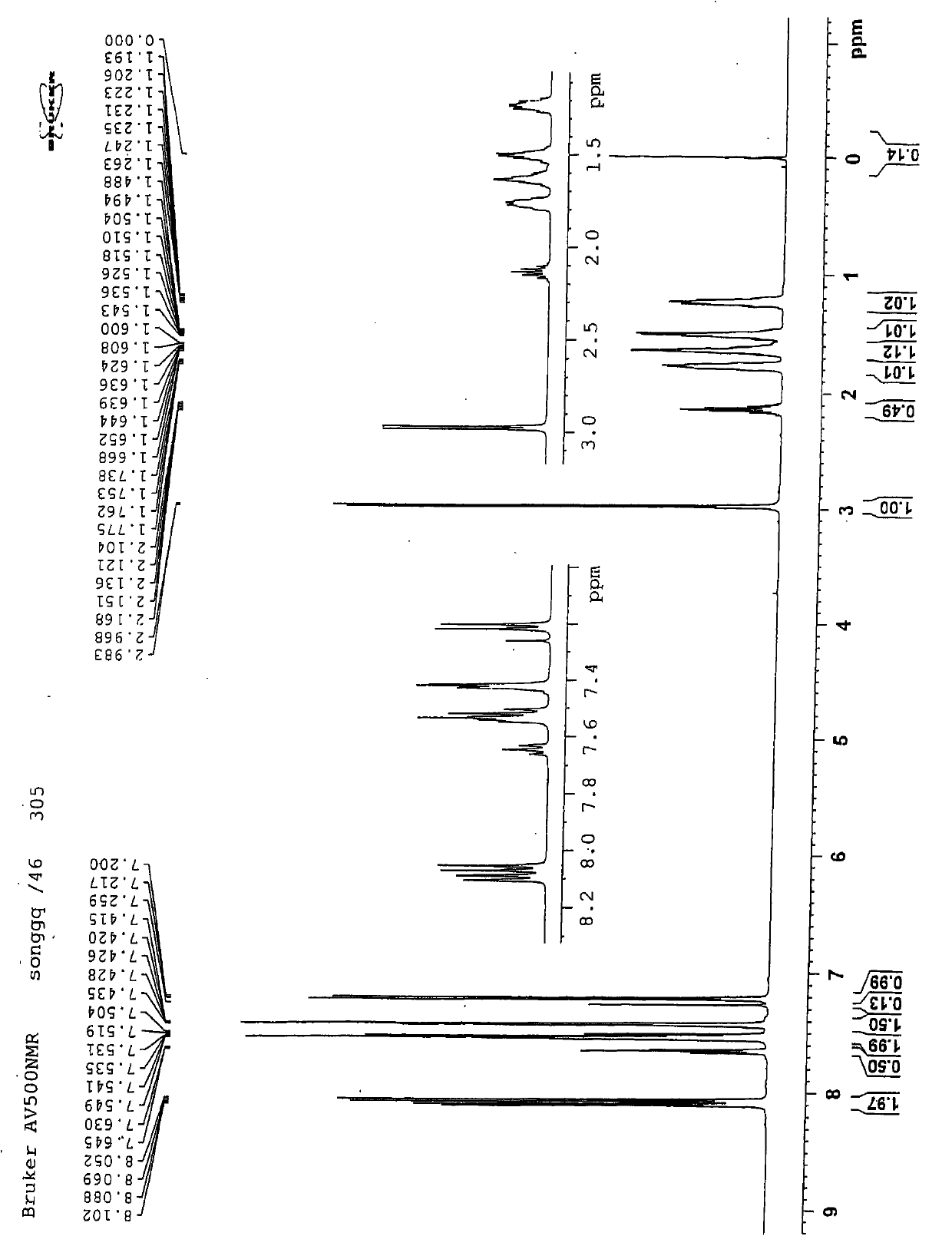

Image

Examples

Embodiment 1

[0028] The preparation method of embodiment one 1-diphenyl sulfide-1-cyclopentyl acetone oxime benzyl ester

[0029] Step 1: Preparation of diphenyl sulfide cyclopentyl acetone

[0030] React operation:

[0031] Put 0.2mol diphenyl sulfide, 0.22mol AlCl3 (finely ground), and 150ml dichloroethane into a 500ml four-neck flask, stir, pass through argon protection, and cool in an ice bath. When the temperature drops to 0°C, start Add 0.22mol cyclopentylpropionyl chloride and 42g dichloroethane cyclopentylpropionyl chloride solution dropwise, the temperature is controlled below 10°C, the addition is completed in about 1.5h, the temperature rises to 15°C, continue to stir for 2h, and discharge.

[0032] Post-processing:

[0033]Under stirring, slowly pour the material into dilute hydrochloric acid made of 400g ice and 65ml concentrated hydrochloric acid, separate the lower layer material liquid with a separatory funnel, extract the upper layer with 50ml dichloroethane, combine the...

Embodiment 2

[0044] Example 2 The preparation method of 1-(6-o-methylbenzoyl-9-ethylcarbazole)-1-cyclopentylacetone oxime benzyl ester

[0045] Step 1: Preparation of 3-(3-cyclopentapropionyl)-6-o-methylbenzoyl-9-ethylcarbazole

[0046] React operation:

[0047] Put 39.0g N-ethylcarbazole, 25.3g AlCl3 (finely ground), 150ml dichloroethane into a 500ml four-neck flask, stir, pass through argon protection, and cool in an ice bath. When the temperature drops to 0°C , began to dropwise add 25.4g of o-toluyl chloride and 21g of dichloroethane in o-toluyl chloride solution, the temperature was controlled below 10°C, the addition was completed in about 1.5h, and the stirring was continued for 2h, then 25.4 g AlCl3 (finely ground), add 42.2g cyclopentapropionyl chloride and 20g dichloroethane cyclohexanecarbonyl chloride solution dropwise, control the temperature below 10°C, drop it in about 1.5h, then raise the temperature to 15°C, and continue to stir for 2h ,Discharge.

[0048] Post-processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com