Limestone powder mineral admixture special for concrete and preparation method thereof

A technology of mineral admixture and limestone powder, which is applied in the field of concrete admixture and its preparation, can solve the problems of reducing the fluidity of concrete, little improvement in cement and concrete performance, and poor sphericity, so as to improve concrete performance and shorten powder The effect of grinding time and improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

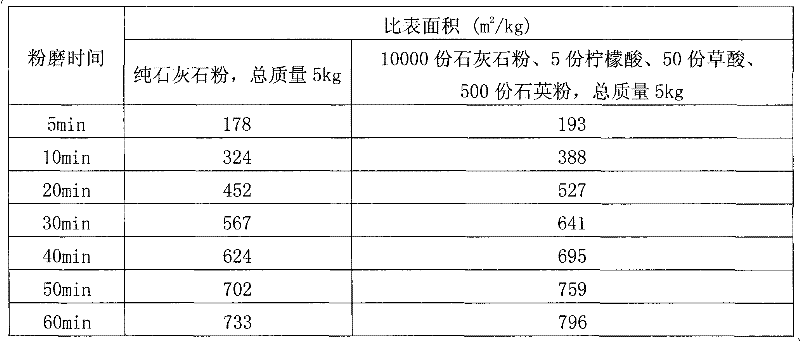

Method used

Image

Examples

Embodiment 1

[0021] Put 5 parts of citric acid, 50 parts of oxalic acid, 500 parts of quartz powder, and 10,000 parts of limestone powder dried at 120°C into the mixer, mix them evenly, then feed them into the ball mill, and grind until the specific surface area is 600m 2 / kg to obtain a special limestone powder mineral admixture for concrete. Adding 20% (mass) of this mineral admixture in P.O42.5, see Table 3 for the impact on cement standard consistency water consumption and setting time.

[0022] Table 3 Effect of a special limestone powder mineral admixture for concrete on the performance of cement slurry

[0023] Performance

[0024] It can be seen from Table 3 that the addition of 20% limestone powder mineral admixture has little effect on the water consumption of cement standard consistency, but the setting time is prolonged by about 40-50 minutes, which has a certain retarding effect.

Embodiment 2

[0026] Put 10 parts of citric acid, 60 parts of oxalic acid, 600 parts of quartz powder, and 10,000 parts of limestone powder (or limestone chips) dried at 100°C into a mixer, mix them evenly, and then feed them into a ball mill and grind them until Surface area 700m 2 / kg to obtain a special limestone powder mineral admixture for concrete. Add 10% (mass) of this mineral admixture in P.O42.5, and the influence on the strength of cement mortar is shown in Table 4.

[0027] Table 4 Effect of a special limestone powder mineral admixture for concrete on the fluidity and strength of cement mortar

[0028]

[0029] It can be seen from Table 4 that the fluidity of cement mortar increases significantly when 10% limestone powder mineral admixture is added. The 3d and 28d flexural strengths both increased, the 3d compressive strength increased significantly, and the 28d compressive strength decreased slightly. The special limestone powder mineral admixture for concrete prov...

Embodiment 3

[0031] Put 10 parts of citric acid, 60 parts of oxalic acid, 600 parts of quartz powder, and 10,000 parts of limestone powder dried at 100°C into the mixer, mix them evenly, then feed them into the ball mill, and grind until the specific surface area is 700m 2 / kg to obtain a special limestone powder mineral admixture for concrete. The concrete test was carried out according to the ratio in Table 5, and the test data are shown in Table 6.

[0032] Table 5 concrete test mix ratio

[0033]

[0034] Table 6 Concrete Properties

[0035] serial number

[0036] It can be seen from Table 5 and Table 6 that when 50kg of limestone powder mineral admixture is used to replace 20kg of cement and 30kg of fly ash, the fluidity of concrete is significantly improved, the slump loss is reduced, the strength of 7d is increased, and the strength of 28d is slightly decreased. The use of the special limestone powder mineral admixture for concrete provided by the invention can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com