Dual-protein based polypeptide soy-bean milk powder and preparation method thereof

A double protein, milk powder technology, applied in food preparation, milk preparations, dairy products, etc., can solve the problems of reduced nutritional value, complex structure, low solubility of soybean protein, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

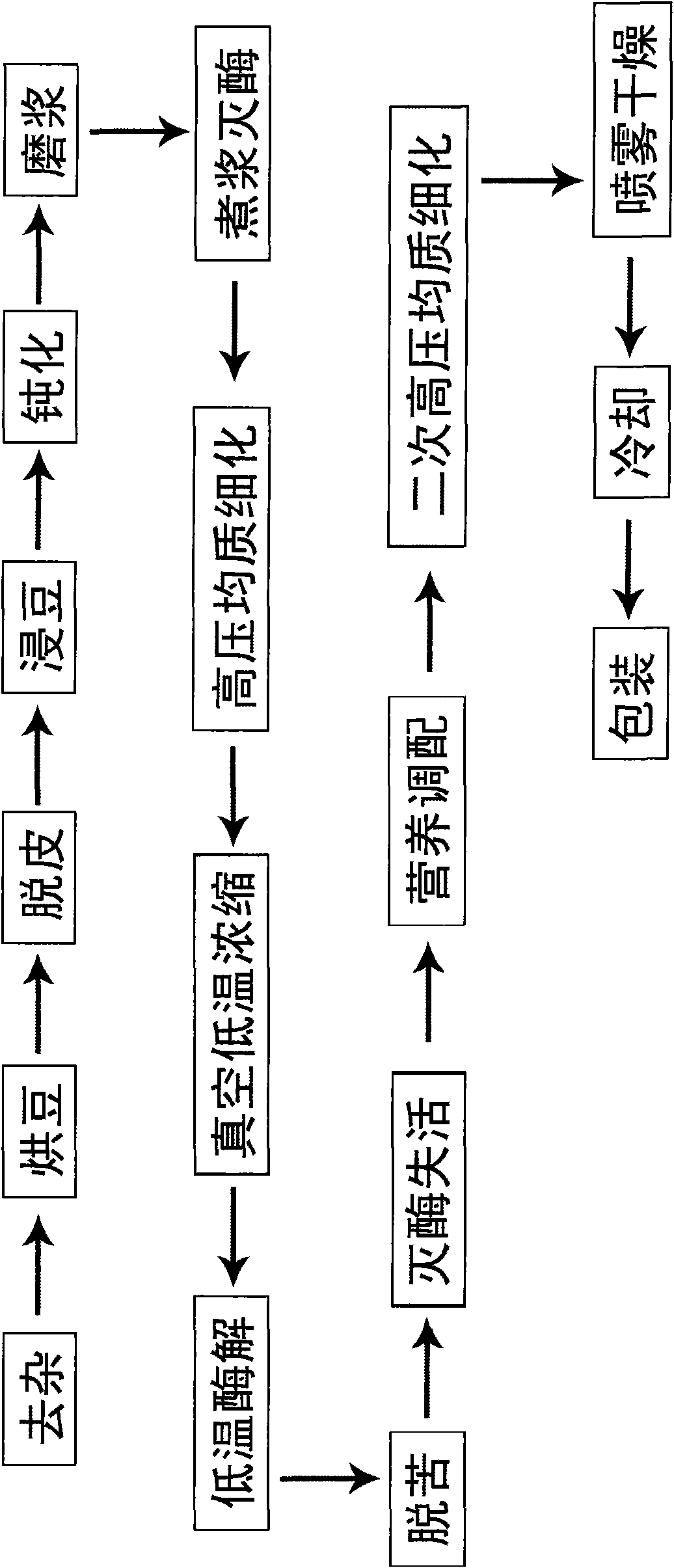

[0171] As shown in the accompanying drawing, the steps to prepare 10kg of double protein-based polypeptide soybean milk powder are as follows:

[0172] 1) Prepare soybeans and perform soybean pretreatment:

[0173] ①Removing impurities to remove impurities in soybeans. According to the principle of specific gravity, sieve out soil, sand and metal in soybeans. At the same time, remove miscellaneous beans and rotten beans, and the removal rate reaches 99%;

[0174] ②Baked beans The baked beans are baked at a temperature of 95°C. After drying, the moisture content of the soybeans is 7.5%, the temperature of the baked beans is uniform, and the local temperature difference is less than 0.2°C; the passivation rate of lipoxygenase reaches 90%, preventing the product from producing beany smell;

[0175] ③The skin and germ of the peeled and dried soybeans fall off under a certain shear force, so that the peeled watercress and soybean skin are separated, and the peeling rate reaches 99%...

Embodiment 2

[0222] The production process of the double-protein-based polypeptide soybean milk powder in Example 2 is basically the same as that of the double-protein-based polypeptide soybean milk powder in Example 1. The difference between the two is:

[0223] Embodiment 2 is from the soybean milk containing soybean polypeptide obtained in Example 1, that is, after the enzyme is inactivated in step 10), the soybean milk containing soybean polypeptide with a dry weight of 3.5 kg is taken out for nutritional preparation; during the nutritional preparation process , the weight of other raw materials is as follows: whole milk powder 2.5kg, maltose syrup 1.8kg, white sugar 1.1kg, edible soybean oil 0.4kg, soybean cellulose 0.4kg, soybean oligosaccharide 0.2kg, edible calcium carbonate 0.1kg;

Embodiment 3

[0225] The production process of the double-protein-based polypeptide soybean milk powder in embodiment 3 is basically the same as that of the double-protein-based polypeptide soybean milk powder in embodiment 1. The difference between the two is:

[0226] Embodiment 2 is from the soybean milk containing soybean polypeptide obtained in Example 1, that is, after the enzyme is inactivated in step 10), the soybean milk containing soybean polypeptide with a dry weight of 3.8 kg is taken out for nutritional preparation; during the nutritional preparation process , the weight of other raw materials is as follows: whole milk powder 2.2kg, maltose syrup 1.6kg, white sugar 1.3kg, edible soybean oil 0.5kg, soybean cellulose 0.2kg, soybean oligosaccharide 0.3kg, edible calcium carbonate 0.1kg;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com