Process technology of boiler for induction cooker

A processing technology and induction cooker technology, which is applied to the processing technology field of aluminum pans for induction cookers, can solve the problems of easy deformation, water vapor infiltration, steel plate falling off, etc., and achieves the effect of low equipment requirements, increased cohesion, and enhanced adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

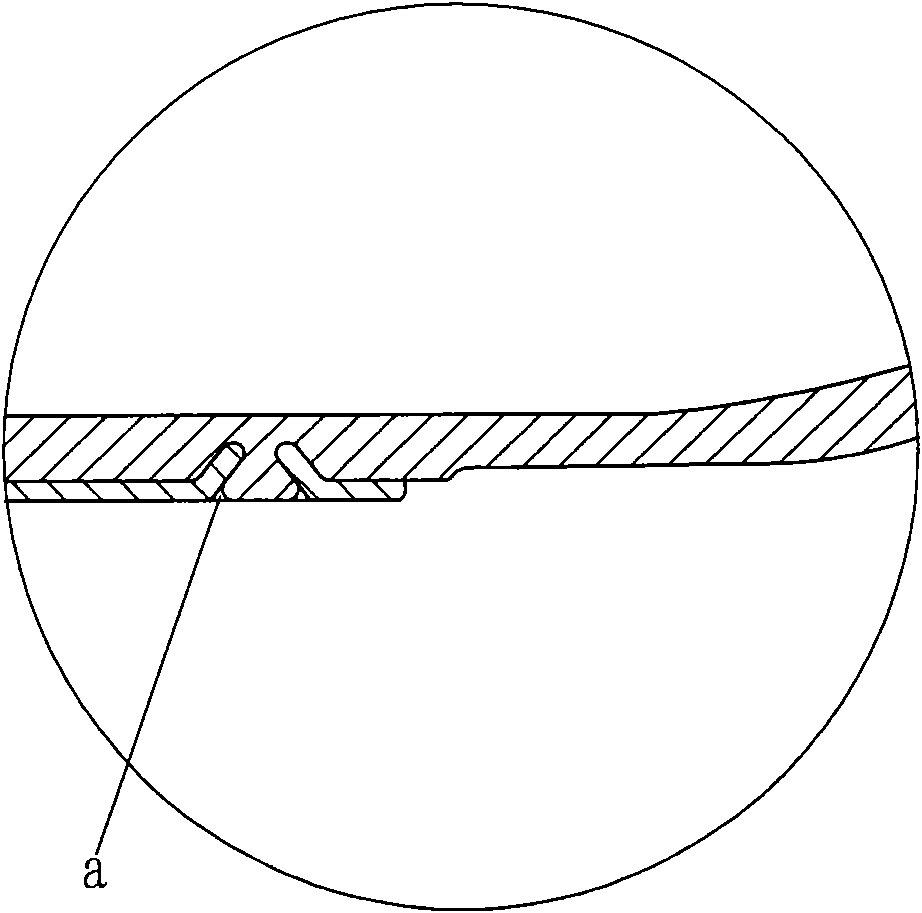

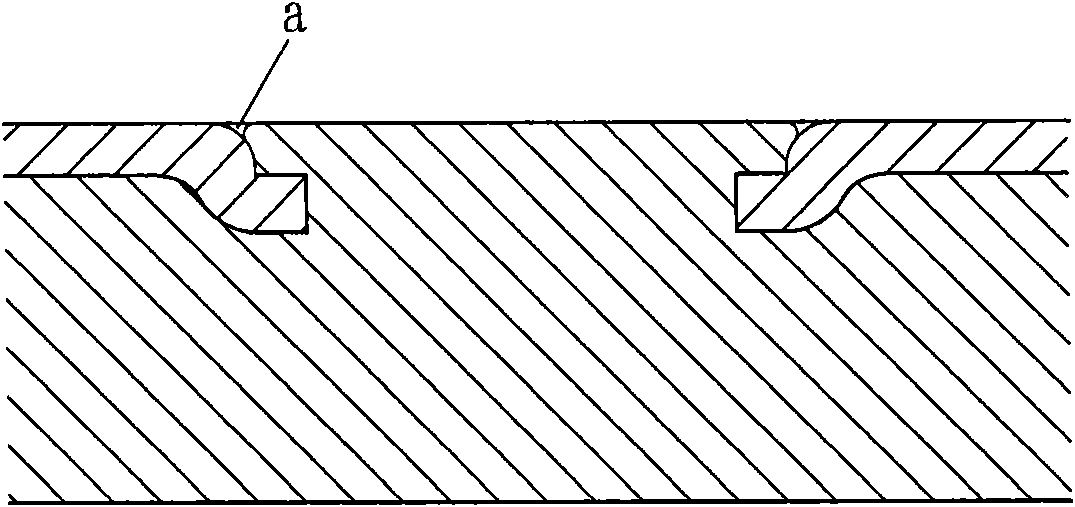

[0041] Such as figure 2 Shown, the processing technology of aluminum pot for electromagnetic cooker of the present invention comprises the following steps:

[0042] Step 1: Casting Process

[0043] Place the pre-processed stainless iron plate 2 with some hollow holes on the plane in the lower cavity 31 of the casting mold (such as Figure 3A ), the cavity inner surface structure of the lower cavity 31 is equivalent to the inner surface structure of the aluminum pot, and the cavity inner surface of the upper cavity 32 of the casting mold is provided with some grooves 33, and the hollow holes of the stainless steel plate 2 are matched with the grooves 33 Relatively, and its shape is identical with this hollow hole, and size is bigger than hollow hole; Then close mold, and adopt the principle of electromagnetic iron absorption, stainless steel plate 2 is fixed on the upper cavity 32 by being arranged on the electromagnetic suction of upper cavity 32 ( Such as Figure 3B ); Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com