A chemical looping combustion power generation process and system using landfill gas

A technology for landfill gas and combustion power generation, which is applied in joint combustion mitigation, chemical instruments and methods, gas treatment, etc., can solve the problems of no large-scale gasification power station, high cost, low separation efficiency, etc., and achieve a wide range of social benefits. and economic benefits, efficient and clean utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

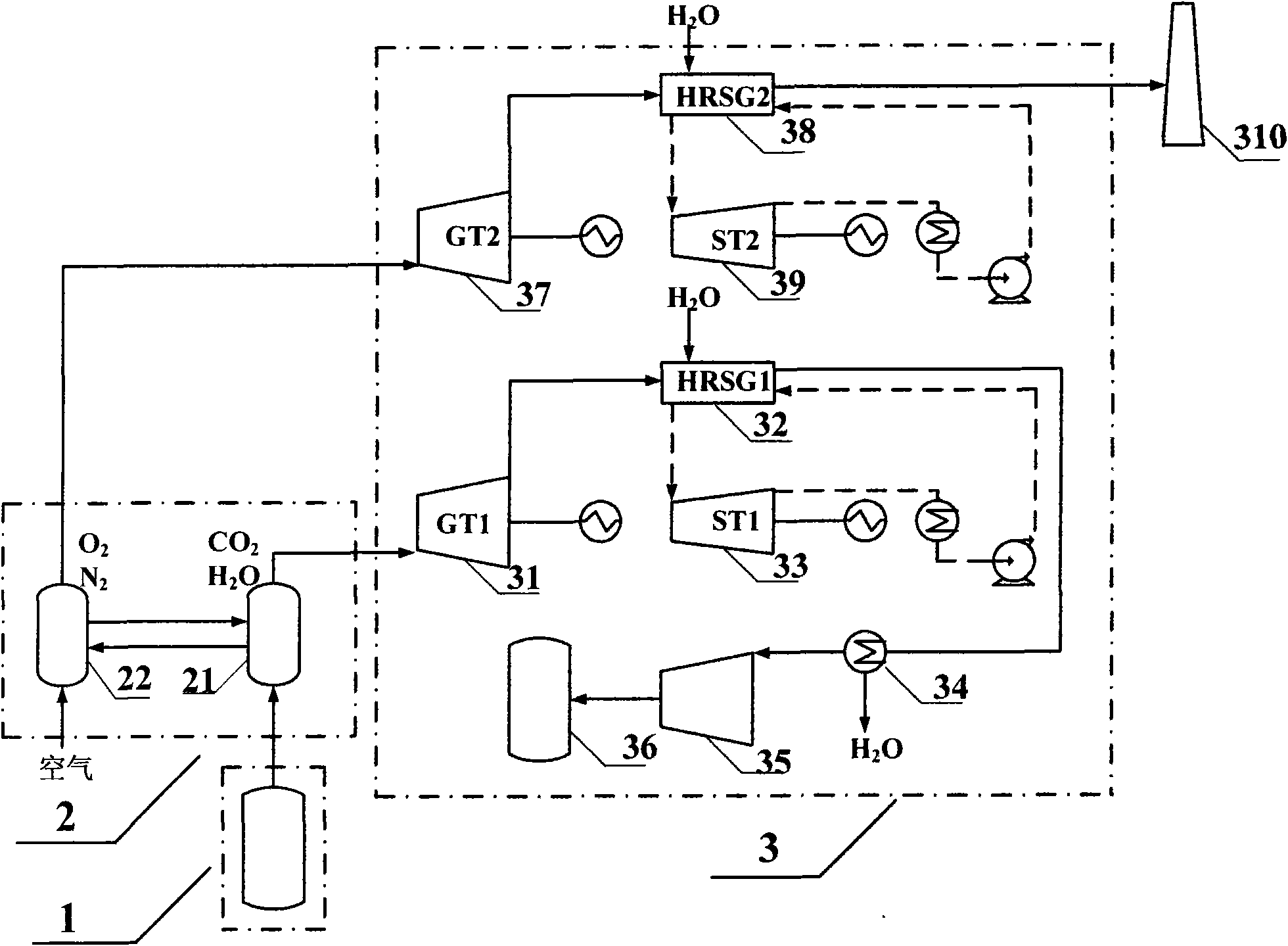

[0013] The invention provides a chemical cascading combustion power generation process and system using landfill gas to separate carbon dioxide from combustion products based on the combustion power generation process of circulating oxygen carriers without additional energy consumption. exist figure 1 Among them, the chemical cascading combustion power generation system using landfill gas is composed of landfill gas collection system 1, chemical cascading combustion system 2 and gas-steam combined cycle power generation system 3. The outlet of the landfill gas gathering system 1 is connected to the inlet of the fuel reactor 21 of the chemical chain combustion system 2, and the outlet of the fuel reactor 21 is connected to the inlet of the first gas turbine 31 of the gas-steam combined cycle power generation system 3, and the first gas turbine The outlet of 31 is connected to the flue gas inlet of the first waste heat boiler 32, the inlet of the first steam turbine 33 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com