Lithium ferrite material applied to C waveband phase shifter

A lithium ferrite and phase shifter technology, which is applied to waveguide devices, electrical components, circuits, etc., can solve problems such as large loss, and achieve the effects of small insertion loss, strong moisture resistance and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A lithium ferrite material applied to a C-band phase shifter, which is made of ingredients with the following weight ratios:

[0060] Li 2 CO 3 10.92%

[0061] MgO 3.97%

[0062] TiO 2 18.86%

[0063] ZnO 1.49%

[0064] Bi 2 o 3 0.2%

[0065] NiO 0.7%

[0066] MnCO 3 4.96%

[0067] Al(OH) 3 0.5%

[0068] Nb 2 o 5 0.5%

[0069] Fe 2 o 3 57.9%

Embodiment 2

[0071] A preparation method of a lithium ferrite material applied to a C-band phase shifter,

[0072] 1) Weigh the ingredients according to the following weight:

[0073] Li 2 CO 3 330 grams

[0074] MgO 120g

[0075] TiO 2 570 grams

[0076] ZnO 45g

[0077] Bi 2 o 3 6 grams

[0078] NiO 21g

[0079] MnCO 3 150 grams

[0080]Al(OH) 3 15 grams

[0081] Nb 2 o 5 15 grams

[0082] Fe 2 o 3 1750 grams

[0083] Total weight 3022 grams.

[0084] 2) One ball mill:

[0085] 3022 grams of ingredients weighed in step 1) were added to 6044ml of distilled water and placed in a ball mill for 23 hours at a speed of 80r / min to mix the ingredients evenly. The ratio of material: water: balls was 1:2:2.

[0086] 3) Drying:

[0087] Dry the ball-milled ingredients in step 2) at 120°C.

[0088] 4) Sieving:

[0089] The batching that step 3) is dried is crossed 30 mesh sieves.

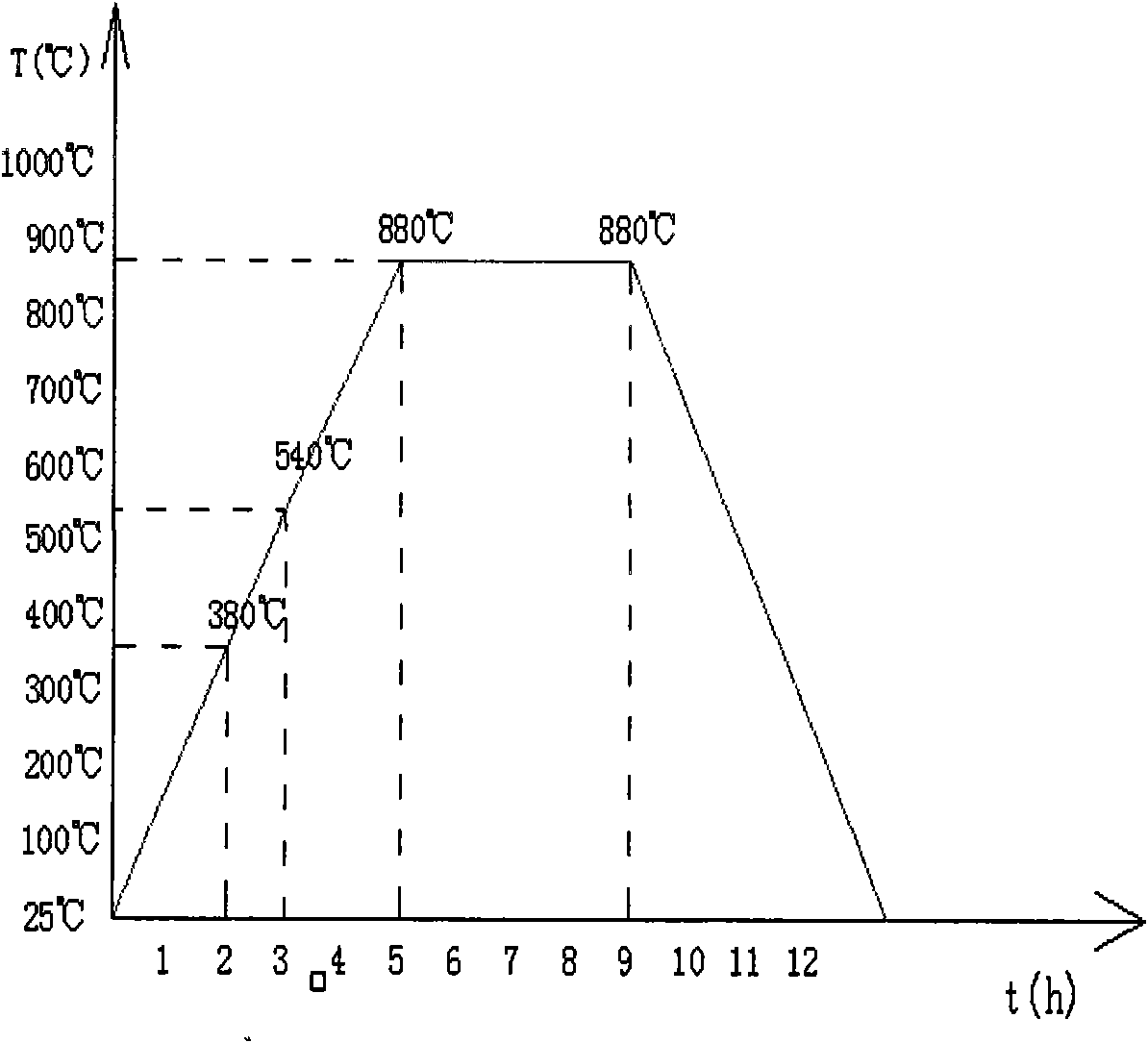

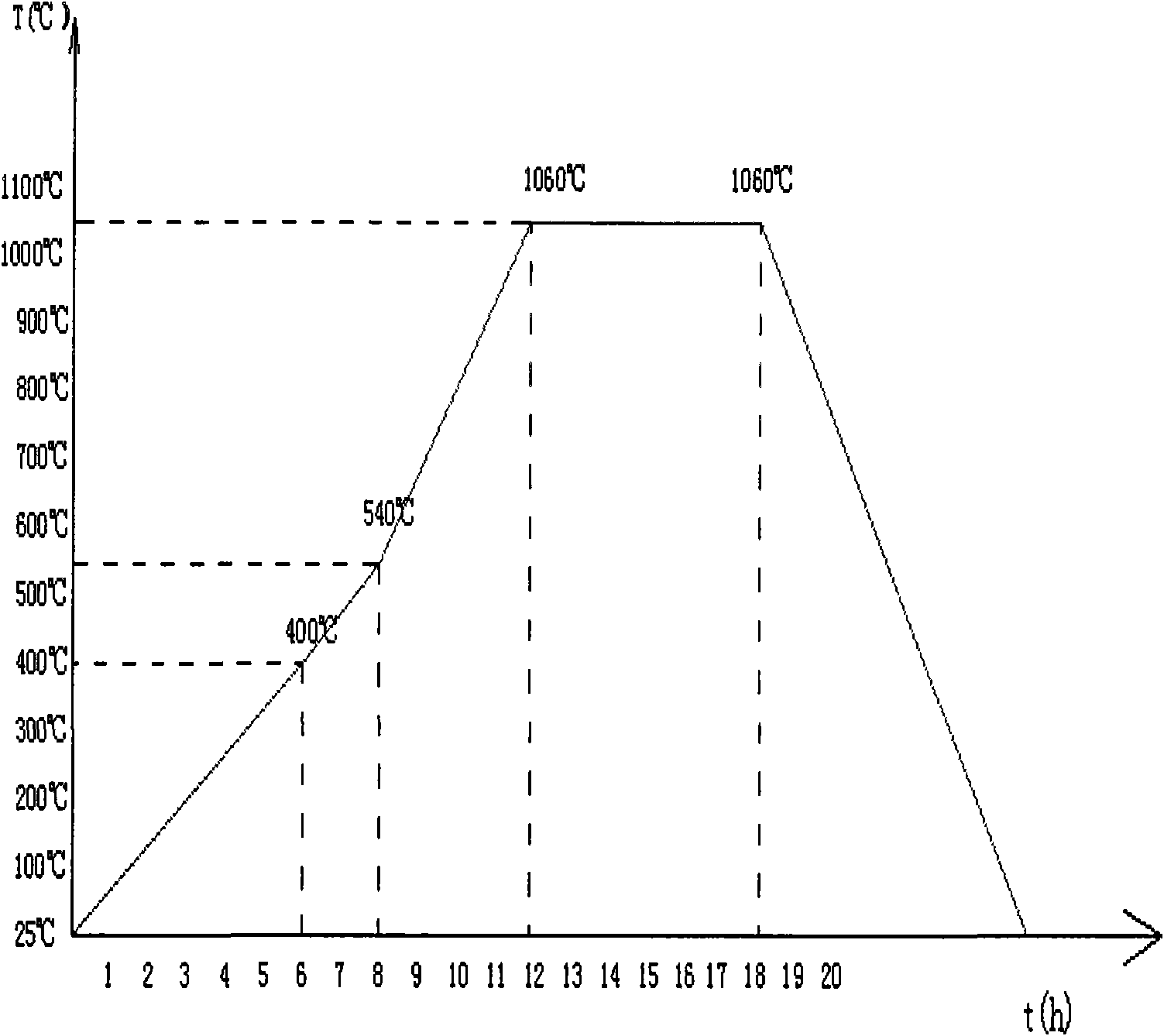

[0090] 5) Pre-burning:

[0091] With step 4) gained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com