Method of preparing cuprous oxide rhombic dodecahedron and low-temperature reduction reaction

A rhombic dodecahedron and cuprous oxide technology, applied in the field of nanomaterials, can solve the problems of difficulty in the rhombic dodecahedron technology, and achieve the effects of cheap raw materials, simple production equipment, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1 The low-temperature preparation steps for preparing cuprous oxide rhombic dodecahedron at low temperature are as follows:

[0020] ① Add CuSO 4 ·5H 2 O was dissolved in deionized water to form a transparent solution with a concentration of 0.025mol / L, then oleic acid and absolute ethanol were added to the transparent solution and stirred thoroughly, and the amounts of oleic acid and absolute ethanol were respectively 4mL and 20mL;

[0021] ②The preparation of step ① containing oleic acid, ethanol and CuSO 4 ·5H 2 After fully stirring the deionized solution of O, heat it to 100°C, and then add a NaOH solution with a concentration of 0.8mol / L and a volume of 10mL for reaction to make it fully react.

[0022] ③ Add 3.42 g of glucose to the fully reacted solution in step ② for reaction, and the reaction time is 20 minutes to form a precipitate. Disperse the precipitate from the solution, wash it in ethanol and cyclohexane for 3-7 times respectively, and finall...

Embodiment 2

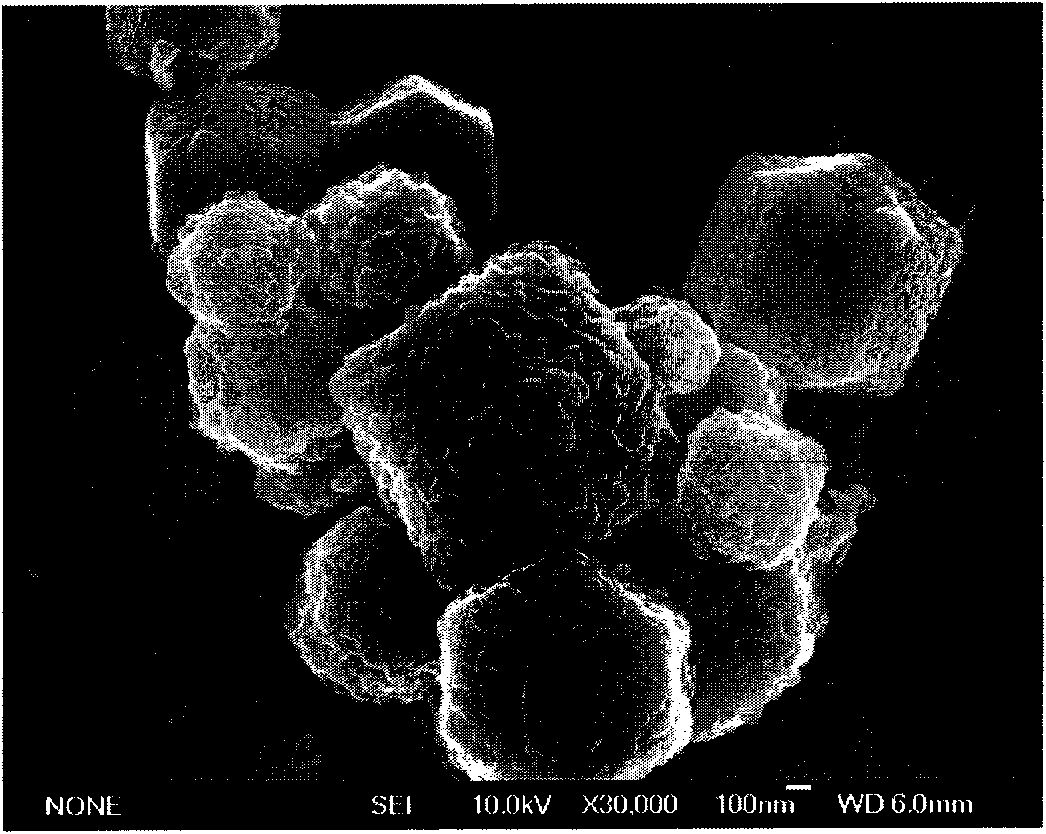

[0024] Add 3.42 g of glucose to the fully reacted NaOH mixed solution prepared in step ② for reaction, and the reaction time is 30 minutes to form a precipitate. Disperse the precipitate from the solution, wash it several times in ethanol and cyclohexane, and finally dry it in a vacuum electric furnace at 60°C to obtain rhombohedral cuprous oxide powder. The rhombic dodecahedron surface smoothness and size uniformity that obtains all increase to some extent than example 1, but dispersibility is relatively poor (see figure 2 ). The technological process of step 1. and 2. is with embodiment 1.

Embodiment 3

[0026] Add 3.42g of glucose to the fully reacted NaOH mixed solution prepared in step ② for reaction, and the reaction time is 60 minutes to form a precipitate. Disperse the precipitate from the solution, wash it several times in ethanol and cyclohexane, and finally dry it in a vacuum electric furnace at 60°C to obtain rhombohedral cuprous oxide powder. The surface of the obtained rhombic dodecahedron is smooth, regular in shape, uniform in size and good in dispersion (see image 3 ). Figure 4 It is the X-ray diffraction pattern of the powder prepared in this embodiment, and the diffraction peaks in the spectrum correspond to the crystal plane diffraction peaks of (110), (111), (200), (220), (311), and (222) successively. It can be seen that The obtained powder is cubic phase Cu 2 O. The technological process of step 1. and 2. is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com