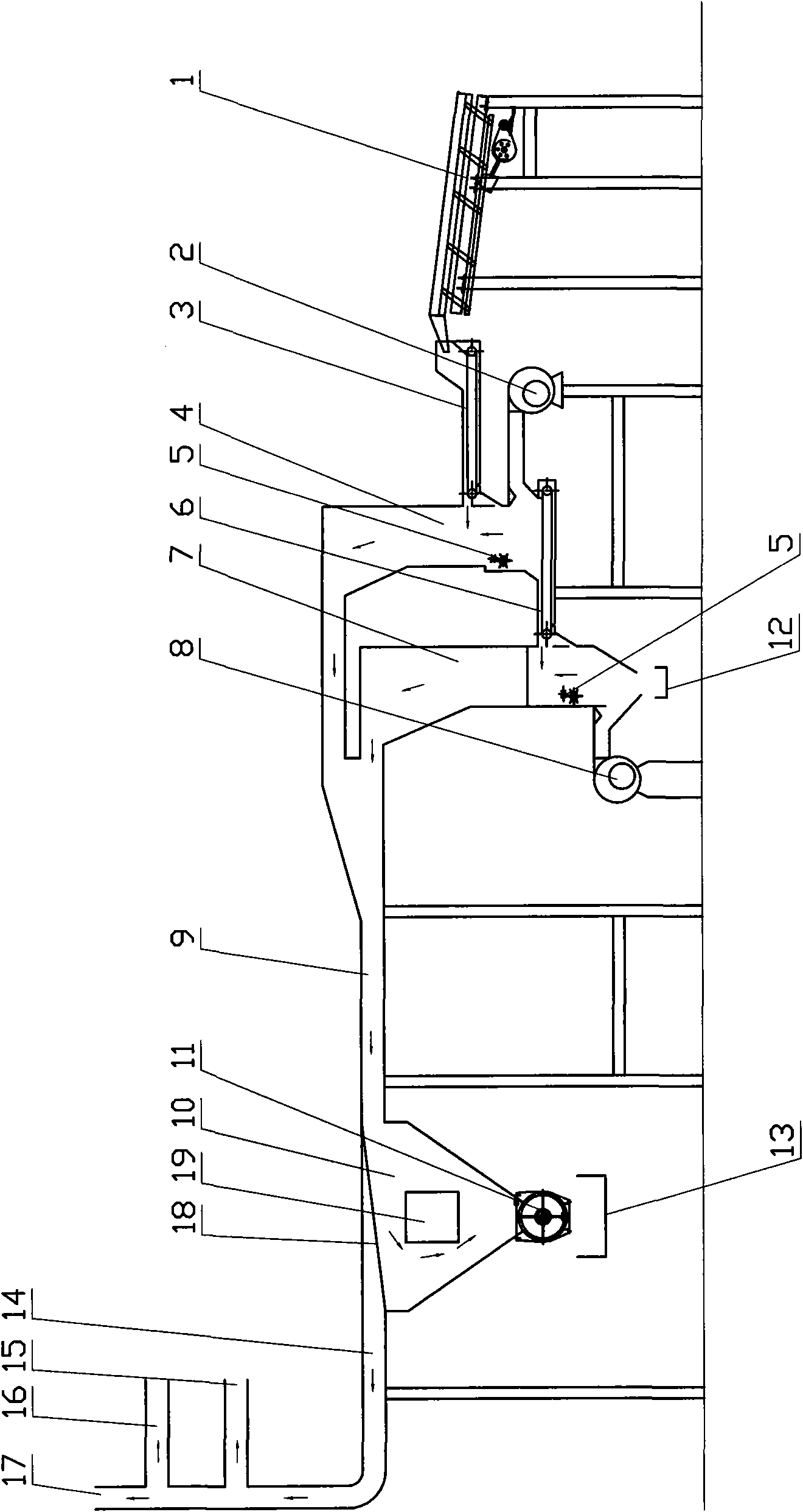

Multistage pneumatic separation device for eliminating stems from tobacco shreds

A technology of multi-stage air and shredded tobacco, which is applied in the direction of separating solids from solids by air flow, tobacco, and preparing tobacco, can solve the problems of insufficient precision, reduced surface area of shredded tobacco, and complexity, and achieves guaranteed product quality, simple structure, Well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

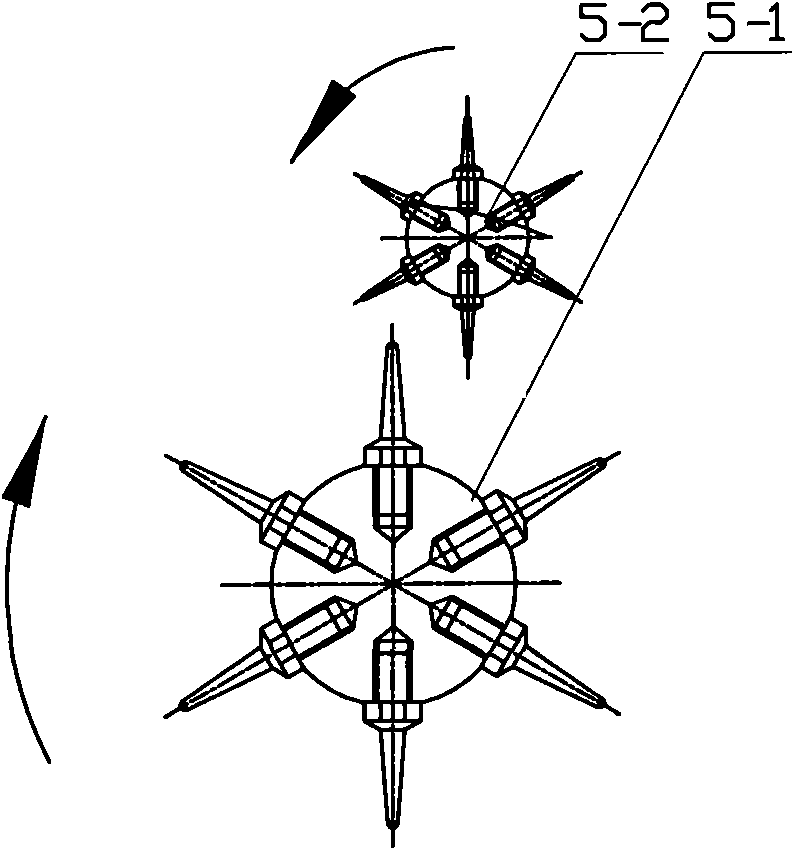

[0009] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings. The working principle of the present invention is to use a multi-stage winnowing device to carry out multiple winnowing for large-flow shredded tobacco. attached figure 1 In the embodiment of the present invention, it is two-stage winnowing, and its working principle is: after the shredded tobacco of large flow enters the winnowing device, firstly carry out the first winnowing, and in the first winnowing process, control the first winnowing mechanism 60% to 90% of the shredded tobacco is selected in the first winnowing. Because the wind speed in the first-level winnowing device is relatively low, the possibility of the stem being selected is relatively low, which can ensure that the shredded tobacco is selected The content of the signed quantity meets the product quality requirements. Then carry out the second winnowing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com