Continuously calibrated magnetic field sensor

A magnetic field sensor and sensor technology, applied in the field of magnetic field sensors, can solve problems such as limited measurement bandwidth, no intention to measure high-frequency current, and difficulty in removing reference signals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

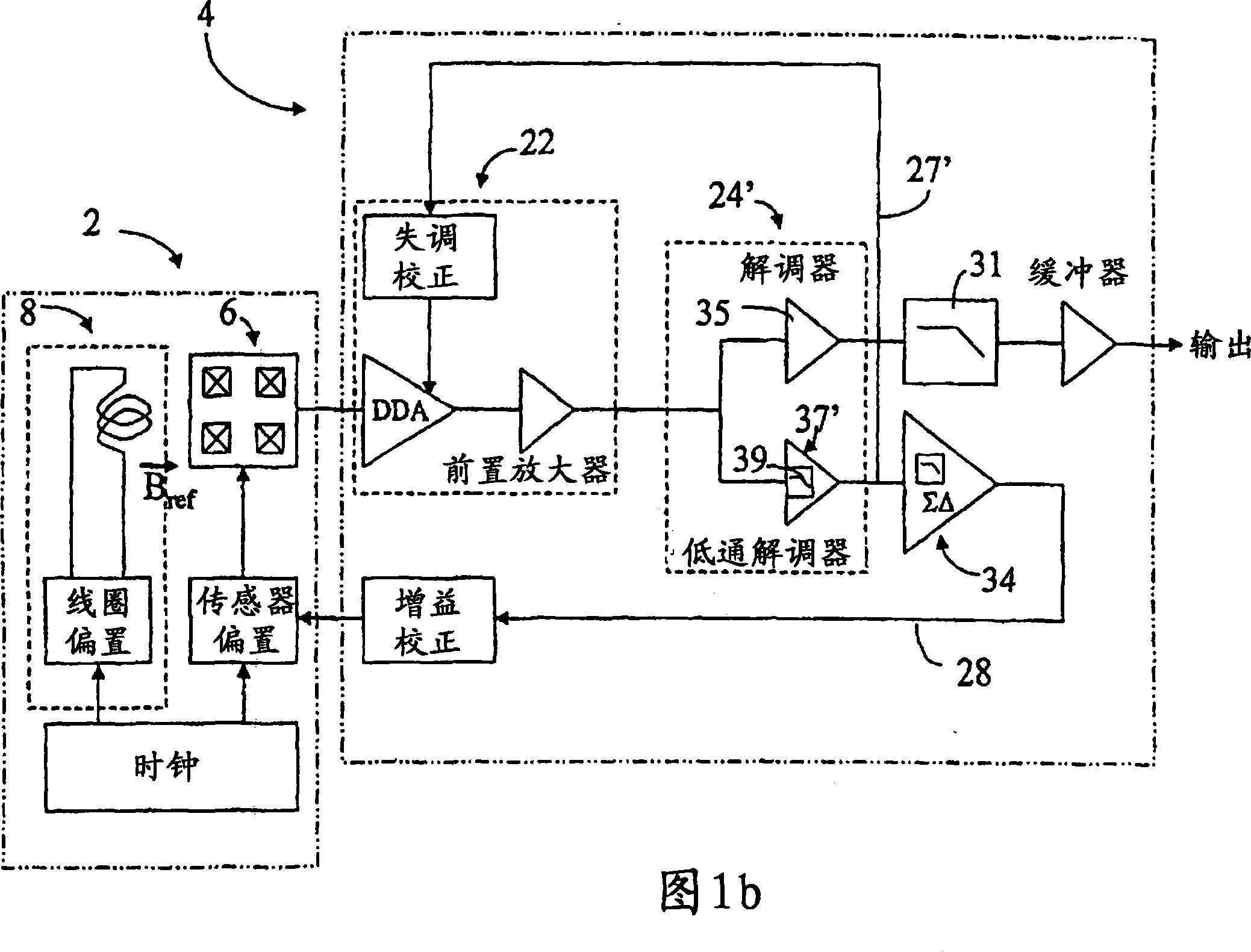

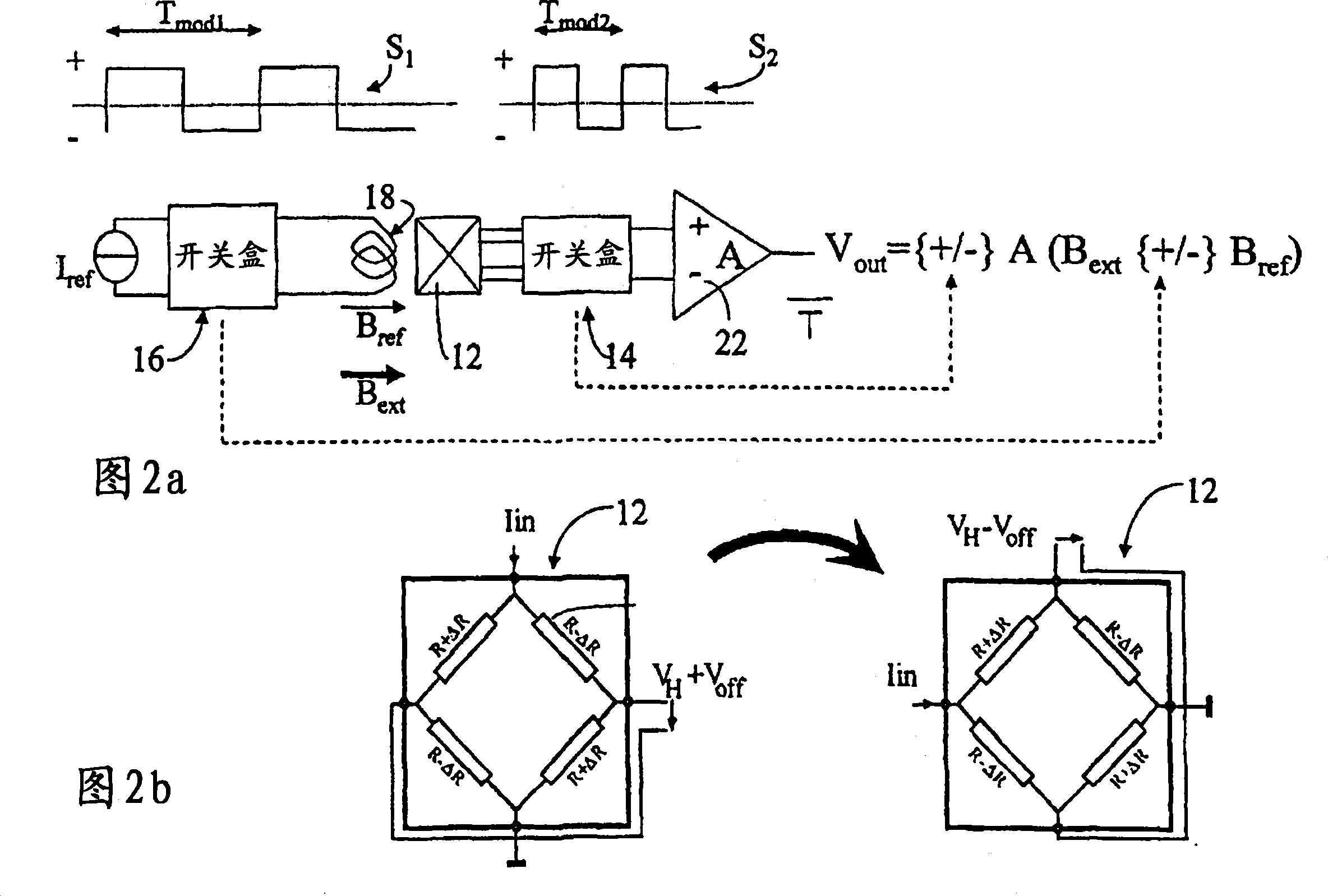

[0031] Referring first to FIGS. 1 a to 3 , the electromagnetic field sensor according to the present invention generally includes a magnetic field sensitive circuit 2 and a signal processing circuit 4 . The magnetic field sensitive circuit 2 includes a magnetic field sensitive unit 6 , a reference magnetic field generator 8 and a gain correction input 10 .

[0032] The magnetic field sensitive unit 6 may include one or more magnetic field sensitive elements 12, such as a Hall effect sensor or Hall effect sensor array formed in an integrated circuit known in the art, and the magnetic field sensitive unit 6 further includes a sensor for modulating each magnetic field sensitive Element 12 outputs modulator 14 of the signal. The reference magnetic field generator 8 includes a modulated reference current input 16 driving one or more reference coils 18 for generating a reference magnetic field Bref to be applied to each magnetic field sensitive element 12 . The frequency of driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com