Energetic film composite type gunpowder and explosive, and preparation method thereof

A propellant and composite technology, applied in explosive processing equipment, explosives, explosive charges, etc., can solve problems such as aluminum powder oxidation, achieve the effects of increasing energy output, small specific surface area, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. The raw materials are TNT and aluminum film strips with a width of 30cm, a length of 5m and a thickness of 0.02mm.

[0020] 2. Put TNT into a water bath and heat it to 80°C to 90°C to melt it into a molten state.

[0021] 3. Evenly coat molten TNT on one side of the aluminum film surface, then directly roll the TNT-coated aluminum film explosive into a cylindrical structure roll, and obtain a cylindrical high-energy film composite explosive (TNT / Al) after solidification .

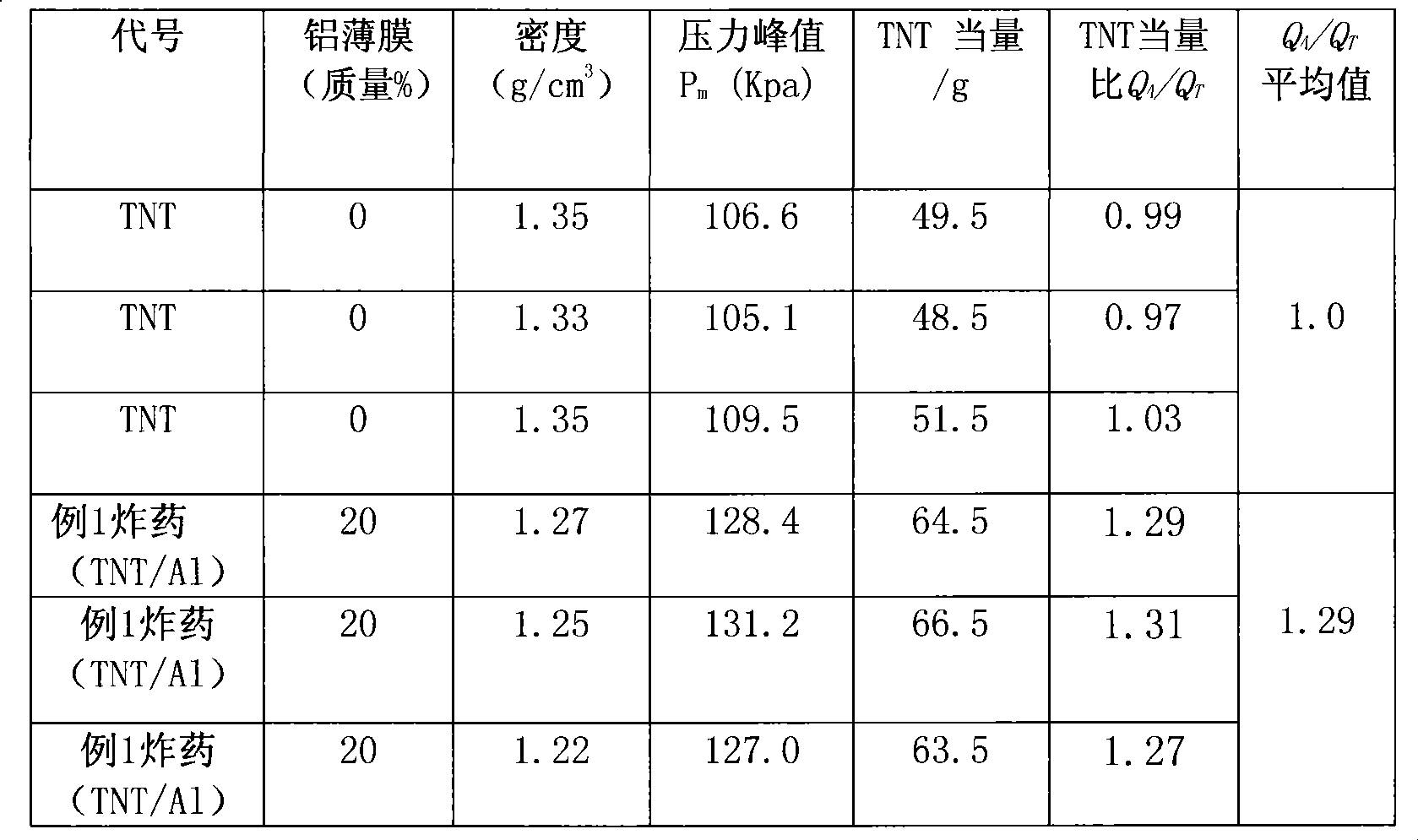

[0022] In this embodiment, no additives are used, that is, the high-energy thin-film composite propellant and explosive consists only of aluminum thin film and TNT charge. For the needs of testing, in the prepared high-energy thin-film composite propellant and explosive, the mass content of the aluminum thin film is respectively 4%, 10%, 20%, 30%, and 40%.

[0023]4. Use the steel plate indentation test method to verify the detonation, detonation transmission and violence of the high-energy film...

Embodiment 2

[0032] 1. Mix RDX, paraffin, and graphite in a mass ratio of 95:4:1, and heat to 80°C.

[0033] 2. Apply the heated explosive paint evenly on one side of the surface of the aluminum film strip (thickness 0.02mm, width 300mm) to make a sheet-like high-energy thin film composite (RDX / Al???) propellant blank.

[0034] 3. Process the sheet-like high-energy film composite propellant and explosive blank into a circular explosive film with a diameter of 25mm, then stack the explosive film layer by layer and put it into a cylindrical mold with a diameter of 25.2mm and pressurize it to 70MPa. After demolding, the stacked Type structured high energy thin film composite explosives

[0035] For the needs of the experiment, the mass content of the aluminum film in the prepared high-energy film composite (TNT / Al???) propellant aluminum film is 10%, 20%, 30%, 40%, 50%, and 60%.

[0036] 4. Use the steel plate indentation test to verify the initiation, transmission and severity of the high-e...

Embodiment 3

[0043] 1. Raw materials: RDX particles, epoxy resin, aluminum film thickness 0.7mm, width 300mm.

[0044] 2. Mix RDX and epoxy resin evenly at a mass ratio of 98:2, put them into a water bath for heating, and mix epoxy resin and RDX evenly to obtain the explosive coating.

[0045] 3. The prepared explosive coating is evenly coated on one side of the surface of the aluminum film (30 cm wide and 40 cm long) to form a sheet-like high-energy film composite (RDX / Al) propellant blank.

[0046] 4. Process the flaky high-energy thin film composite propellant and explosive billet into a circular explosive film with a diameter of 25mm, then stack the explosive film layer by layer into a cylindrical mold with a diameter of 25.2mm and pressurize to 70MPa. After demoulding, the obtained High energy thin film sandwich structure composite explosive grain. The mass content of the high-energy film composite (RDX / Al???) propellant aluminum film prepared in the laboratory is 20% and 30% respect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Column height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com