Preparation method for novel high temperature resisting organic fire prevention heat insulating material

A heat-insulating material and high-temperature-resistant technology, which is applied in the field of preparation of new high-temperature-resistant organic fire-proof and heat-insulating materials, can solve the problems of no high-temperature-resistant organic fire-proof and heat-insulating materials, and achieve the effects of stable size, easy decoration, and long fire-resistant time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

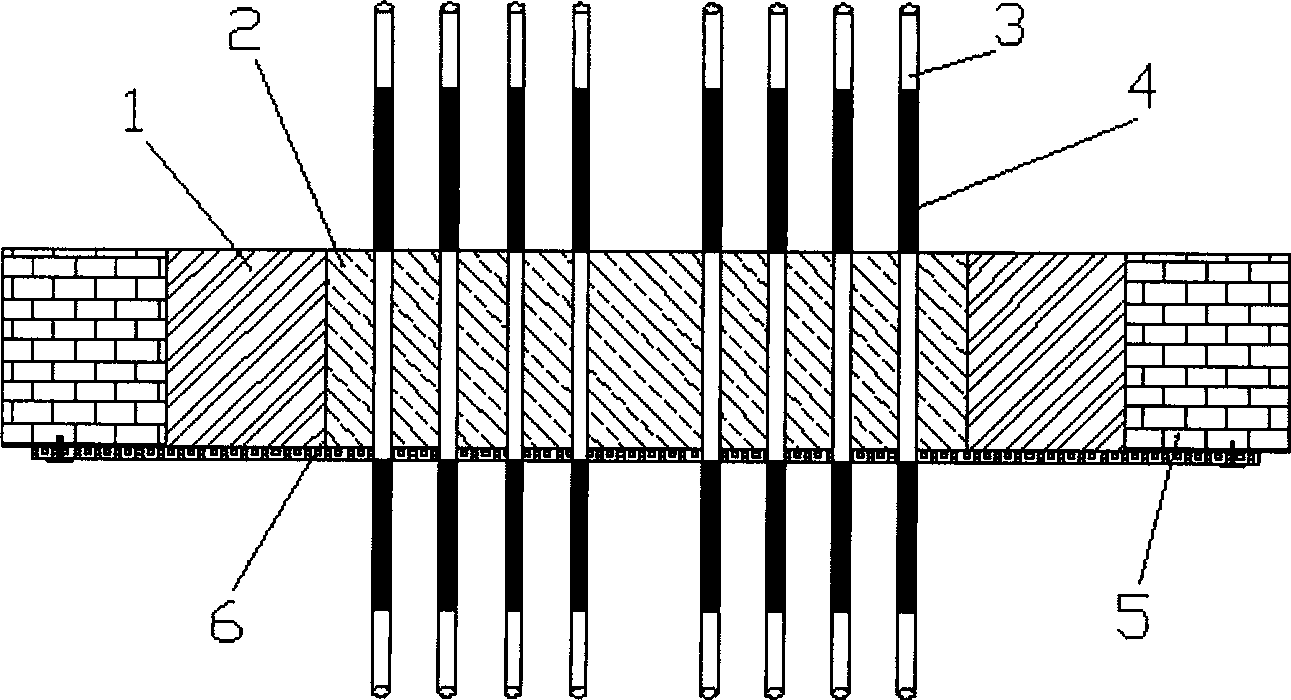

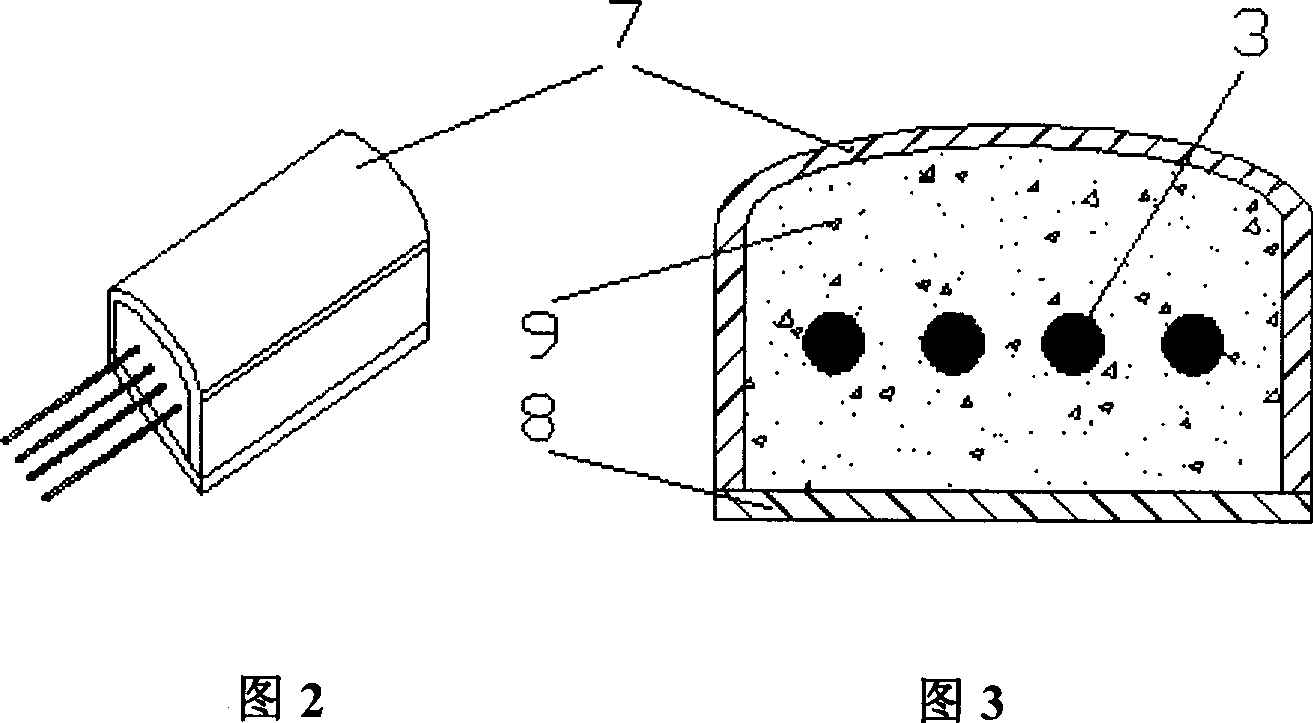

Method used

Image

Examples

specific example 1

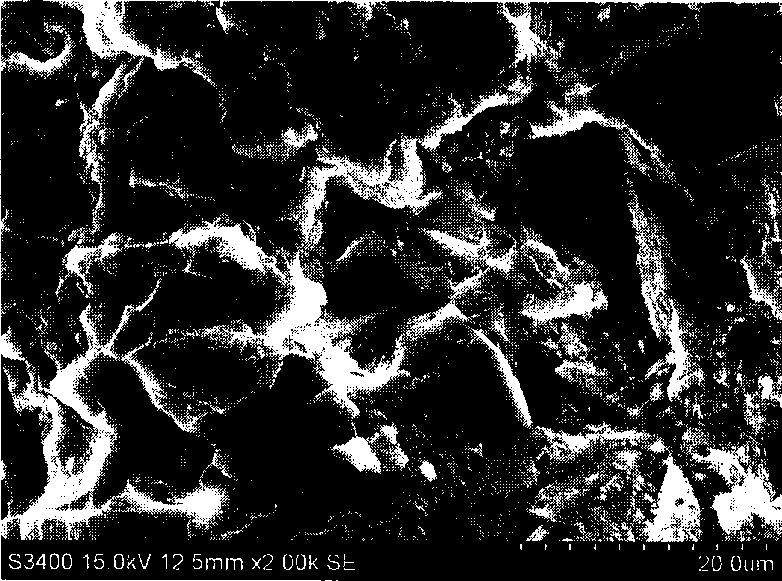

[0041] 1. Polymethyl silicone resin SAR-9 (produced by Shanghai Resin Factory, colorless uniform transparent liquid, solvent is toluene, solid content 51%, viscosity is 13-50mPa·s) and alumina micropowder according to 33; 67 After the mass ratio (the ratio after desolventizing toluene) is mixed, they are placed in a constant temperature oven at 120° C. and kept warm for 10 hours.

[0042] 2. Put the pre-pressed coated powder into a specific heating mold while it is hot, and set the heating and pressure-holding molding process system as follows: raise the temperature to 120°C and keep it for 0.5 hours, and no axial pressure is applied during this process; Heat at 150°C for 1.5 hours while applying an axial pressure of 25 MPa, which is the molding pressure; keep the molding pressure constant, raise the temperature to 180°C and hold for 1 hour, and finally raise the temperature to 200°C for 0.5 hours.

[0043] 3. After releasing the pressure and demoulding, put the molded materia...

specific example 2

[0046] 1. After the silicone resin (Dow Corning Silicone Resin SR249 in the United States) and the alumina micropowder are mixed according to the mass ratio of 26:74, an appropriate amount of toluene is added to mix the two evenly, and then placed in a constant temperature oven at 120°C and kept for 5 hours.

[0047] 2. Put the pre-pressed coated powder into a specific heating mold while it is hot, and set the heating and pressure-holding molding process system as follows: raise the temperature to 120°C and keep it for 0.5 hours, and no axial pressure is applied during this process; Heat to 150°C, hold for 1.5 hours, and apply 30MPa axial pressure at the same time, the pressure is the molding pressure; keep the molding pressure constant, raise the temperature to 180°C and hold for 1 hour, and finally rise to 200°C for 0.5 hours.

[0048] 3. After releasing the pressure and demoulding, put the molded material into a constant temperature oven at 250°C and treat it for 6 hours to ...

specific example 3

[0051] 1. Polymethyl silicone resin SAR-9 (produced by Shanghai Resin Factory, colorless uniform transparent liquid, solvent is toluene, solid content 51%, viscosity is 13-50mPa s) and alumina micropowder according to 35; 65 After the mass ratio (the ratio after desolventizing toluene) is mixed, they are placed in a constant temperature oven at 120° C. and kept warm for 10 hours.

[0052] 2. Put the pre-pressed coated powder into a specific heating mold while it is hot, and set the heating and pressure-holding molding process system as follows: raise the temperature to 120°C and keep it for 0.5 hours, and no axial pressure is applied during this process; Heat at 150°C for 1.5 hours while applying an axial pressure of 25 MPa, which is the molding pressure; keep the molding pressure constant, raise the temperature to 180°C and hold for 1 hour, and finally raise the temperature to 200°C for 0.5 hours.

[0053] 3. After releasing the pressure and demoulding, put the molded materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com