Suspension bed hydrocracking catalyst and preparation method and application thereof

A hydrocracking and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of small application scale, poor economic rationality, complicated steps, etc. problems, achieve good performance, solve difficult processing, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

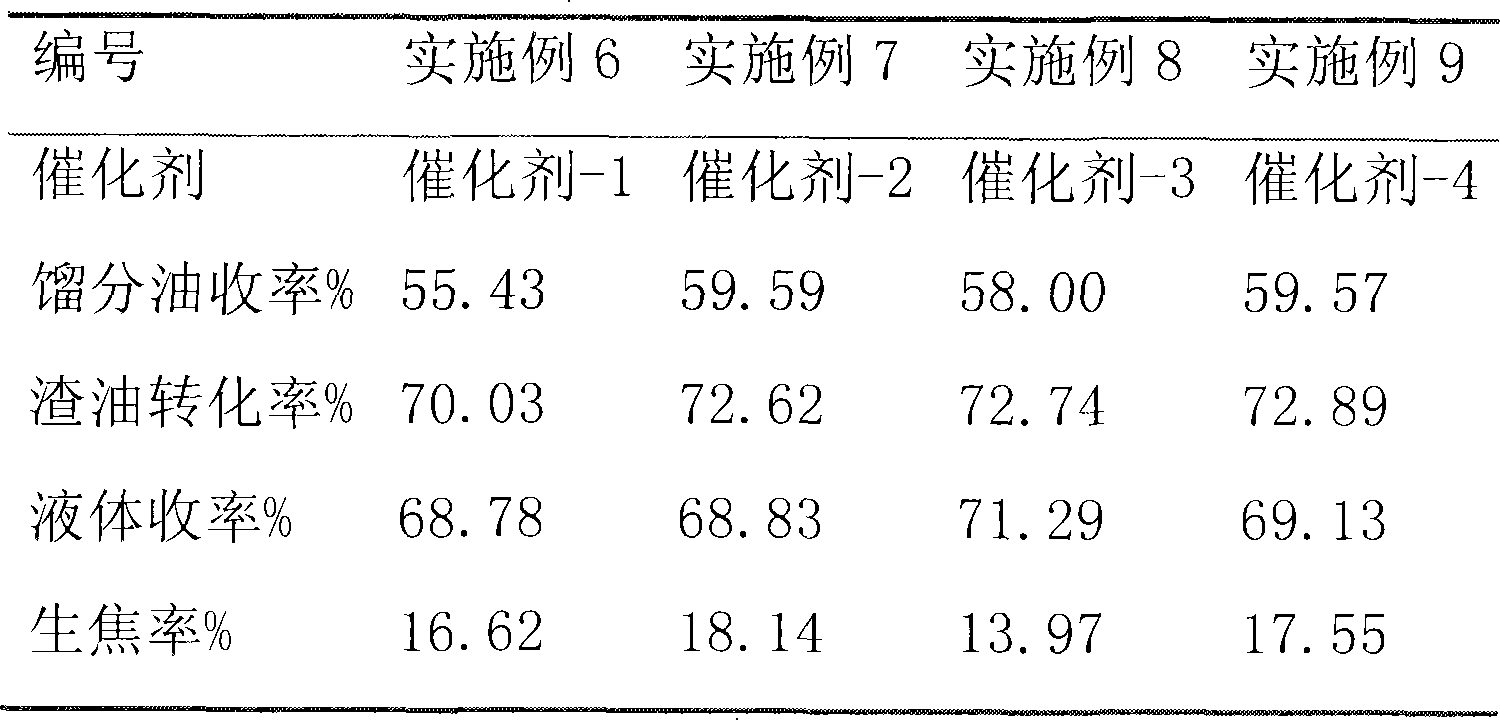

Embodiment 1

[0054] Spent catalyst from catalytic cracking (Shijiazhuang Refinery, Fe 2 o 3The content is 0.3wt%, and the specific surface area is 240m 2 / g) to sieve the part below 120 mesh, weigh 95.00g into a 250ml petri dish; weigh nickel nitrate Ni(NO 3 ) 2 .6H 2 O 19.47g into a beaker, then add 47.50g deionized water to dissolve; constantly stir the spent catalyst powder in the petri dish, add nickel nitrate aqueous solution drop by drop; dry at 100-120°C for 3h, and roast at 450°C for 3h to obtain Catalyst, designated Catalyst-1.

Embodiment 2

[0056] Spent catalyst from catalytic cracking (Shengli Petrochemical General Plant, Ni content 1900ug / g, V content 4100ug / g, specific surface area 150m 2 / g) to sieve the part below 120 mesh, weigh 95.00g to a 250ml petri dish; weigh 4.87g ammonium molybdate ((NH 4 ) 6 MO 7 o 24 .4H 2 (0) into a beaker, then add 47.50g deionized water to dissolve; constantly stir the waste catalyst powder in the petri dish, add ammonium molybdate aqueous solution drop by drop; dry 3h at 100~120°C; then weigh nickel nitrate (Ni( NO 3 ) 2 .6H 2 (0) 4.01g into a beaker, then add 48.50g deionized water to dissolve; constantly stir the waste catalyst powder in the petri dish, add nickel nitrate aqueous solution drop by drop; dry at 100~120°C for 3h, and roast at 450°C for 3h, A bimetallic catalyst with a molar ratio of molybdenum and nickel of 1:0.5 was obtained, which was designated as Catalyst-2.

Embodiment 3

[0058] Spent catalyst from catalytic cracking (Shijiazhuang Refinery, Fe 2 o 3 The content is 0.3wt%, and the specific surface area is 240m 2 / g) to sieve the part below 120 mesh, weigh 95.00g to 250ml petri dish; weigh 3.45g ammonium molybdate ((NH 4 ) 6 MO 7 o 24 .4H 2 (0) into a beaker, then add 47.50g deionized water to dissolve; constantly stir the waste catalyst powder in the petri dish, add ammonium molybdate aqueous solution drop by drop; dry 3h at 100~120°C; then weigh nickel nitrate (Ni( NO 3 ) 2 .6H 2 (2) 8.52g in the beaker, then add 48.50g deionized water to dissolve; constantly stir the waste catalyst powder in the petri dish, add nickel nitrate aqueous solution drop by drop; dry at 100~120°C for 3h, and roast at 450°C for 3h, A bimetallic catalyst with a molar ratio of molybdenum and nickel of 1:1.5 was obtained, designated Catalyst-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com