Microwave-assisted continuous flow large-scale polypeptide synthesis method and device

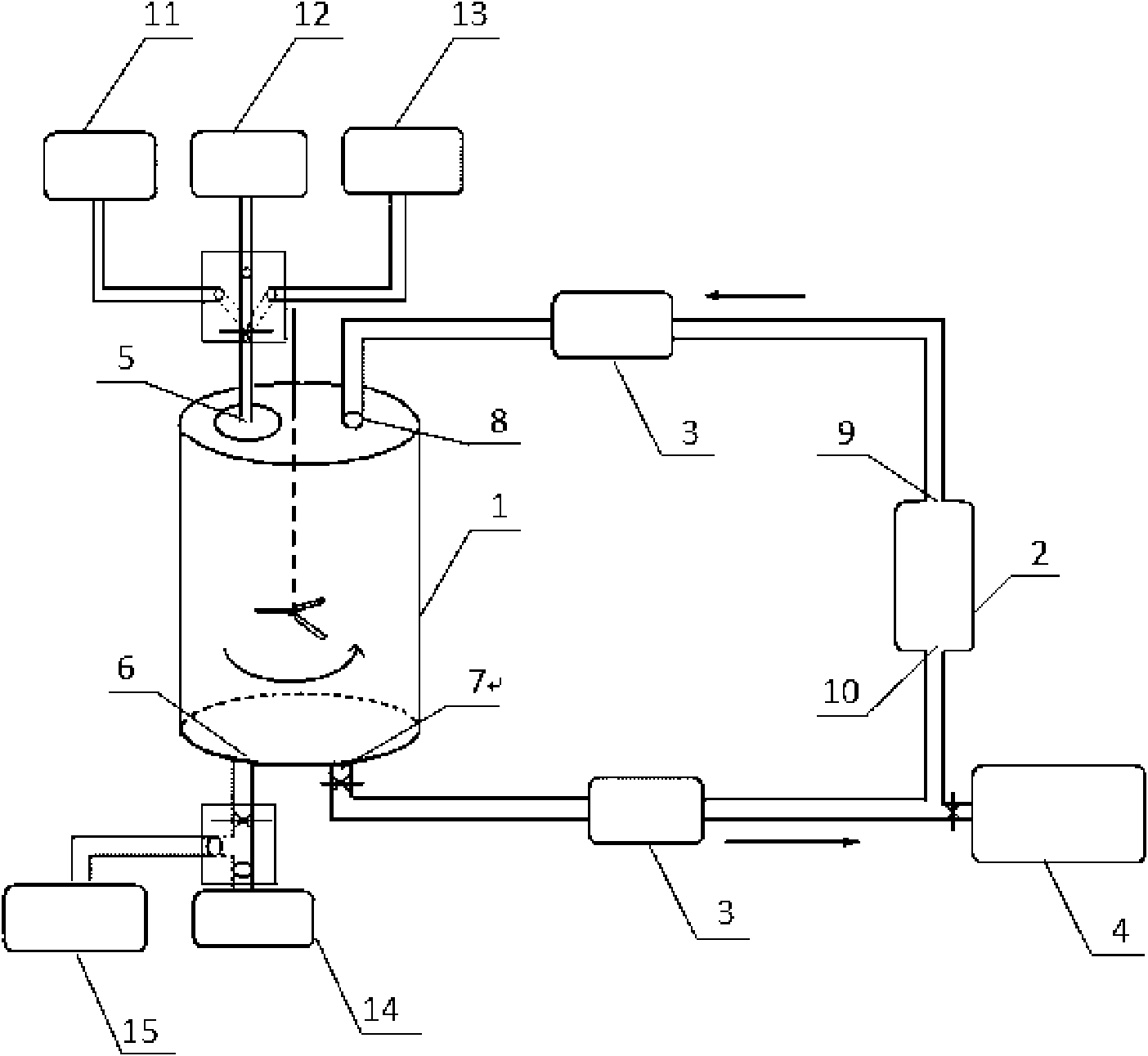

A synthesis device and microwave-assisted technology, which is applied in the field of microwave-assisted continuous flow large-scale peptide synthesis method and its device, can solve the problems of low output, low efficiency and low yield, etc., and achieve increased output, shortened reaction time, and significant social impact. Effects on Value and Economic Benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation of embodiment 1 Thymopentin

[0041] ① Put 5.25kg of Fmoc-Tyr(tBu)-Wang resin with a degree of substitution of 0.4mmol / g into the reactor, add 30L of deprotecting group reagent, start the pump to circulate the reactants between the microwave reaction center and the reactor, and turn on the microwave The microwave generating device in the reaction center enables it to generate microwaves, and the microwave settings are: 70°C, 1.2MPa. When the reactant passes through the microwave reaction center, the reaction of removing the amino protecting group is accelerated under microwave radiation. After 5 minutes, turn off the pump and stop the microwave radiation, filter off the deprotecting group reagent, add reagent DMF 10.5L to wash the resin 3 times, and drain with nitrogen gas. According to the polypeptide sequence, add pre-activated Fmoc-Val-OH and coupling reagent HBTU to the reaction kettle, the molar ratio of the reagents used is raw resin: Fmoc-Val-OH:...

Embodiment 2

[0044] The preparation of embodiment 2 Thymopentin

[0045] The polypeptide to be synthesized in this example and the operation are exactly the same as in Example 1, only the process conditions used are different.

[0046] ① The time of microwave irradiation is 20 minutes, the resin is washed 5 times after filtering off the deprotecting group reagent, and the resin is washed 3 times after filtering off the residual amino acid and reagent liquid, and the rest are the same as in Example 1.

[0047] 2., 3. steps are with embodiment 1. Obtain 1.38kg of crude polypeptide. The purity measured by liquid chromatography was 92.5%, and the yield was 96%.

Embodiment 3

[0048] Example 3 Preparation of Glucagon-Like Peptide-1 (Glucagon-Like Peptide I)

[0049] ① Put 1.26kg of Fmoc-Arg(Pbf)-Amide resin with a degree of substitution of 0.4mmol / g into the reactor, add 10L of deprotecting group reagent, start the pump to circulate the reactant between the microwave reaction center and the reactor, and turn on the microwave The microwave generating device in the reaction center enables it to generate microwaves, and the microwave settings are: 70°C, 1.2MPa. When the reactant passes through the microwave reaction center, the reaction of removing the amino protecting group is accelerated under microwave radiation. After 1 minute, turn off the pump and stop the microwave radiation, filter off the deprotecting group reagent, add reagent DMF 12.6L to wash the resin 3 times, and drain with nitrogen gas. According to the polypeptide sequence, add pre-activated Fmoc-Gly-OH and coupling reagent HBTU to the reaction kettle, the molar ratio of the reagents i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com