Waterproof voile production technology, and special production equipment thereof

A production process and production equipment technology, which is applied in the field of water-blocking glass yarn production process and special production equipment, can solve the problems affecting the quality of optical cable transmission signals, complex and tedious processes, and high process requirements, so as to improve the ability of acid and alkali resistance, process Easy process and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] Embodiment: A production process of water-blocking glass yarn, the steps are as follows:

[0043] The first step: prepare raw materials, the raw material is 120 rolls of glass fiber; configure the water barrier solution, the water barrier solution is 35 parts of water, 5 parts of acrylic acid, 2-2.5 parts of 30% sodium hydroxide aqueous solution (neutralization degree is controlled at 60%- 80%), 0.1-0.15 parts of cross-linking agent (optional acrylamide, N, N-methylene acrylamide, hydroxyethyl methacrylate, etc.), 0.1-0.2 parts of initiator (optional potassium persulfate, per ammonium sulfate, etc.), add softeners, thickeners, adhesives and other additives to the water-repellent solution according to the actual situation; configure glue, the glue is 10 parts of polyacrylate emulsion (Dow B-959 emulsion, solid Content 50%) and 150 parts of pure water.

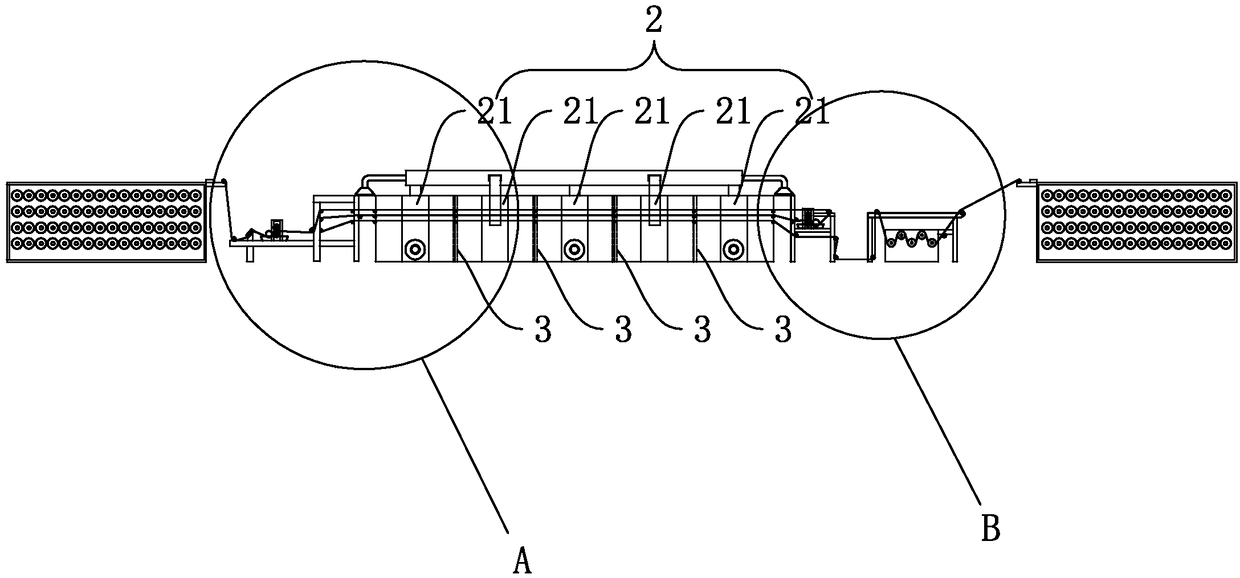

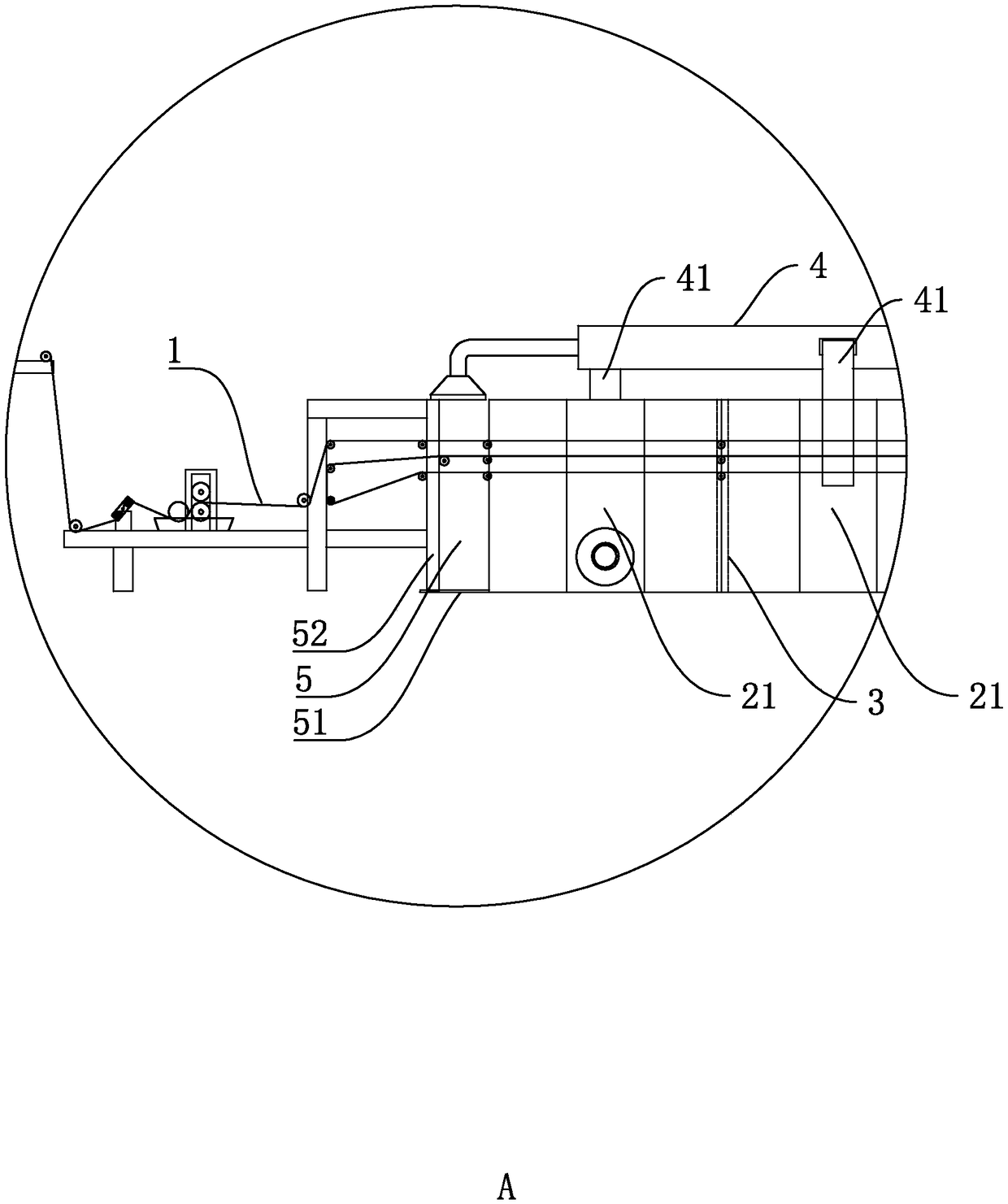

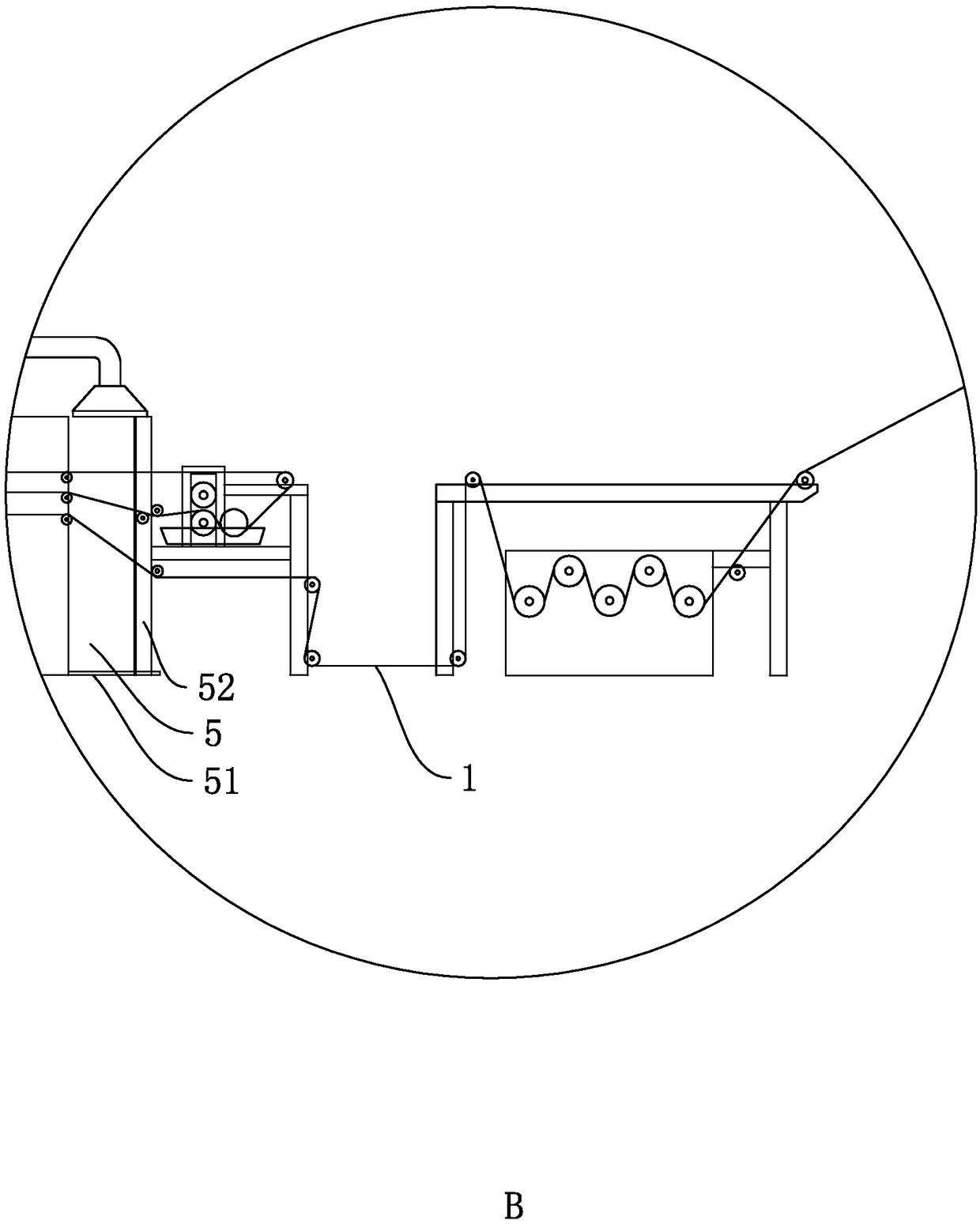

[0044] Step 2: Hang 120 rolls of glass fiber on the wire-feeding frame, the edge of which is the wire-feeding frame, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com