Transparent electroconductive resin, color film substrate and its manufacturing method, liquid crystal display device

A technology for transparent conductive and color filter substrates, applied in the fields of transparent conductive resins, liquid crystal display devices, color filter substrates and their manufacturing methods, can solve the problem of unsatisfactory conductive effect of protective layers, reduced optical transparency of coatings, and reduced performance of liquid crystal display panels and other problems to achieve the effect of ensuring production safety and production efficiency, good light transmittance and conductivity, and eliminating breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

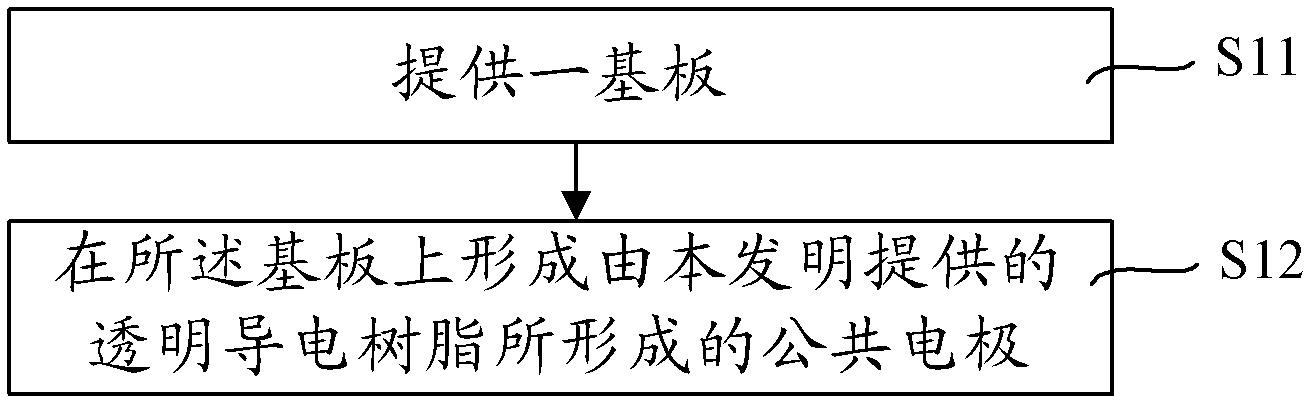

Method used

Image

Examples

Embodiment 1

[0038] 32g acrylate resin, 6g organic acid-doped polyaniline, 3g trimethylolpropane triacrylate, 0.1g benzoyl peroxide (curing initiator) are added in 60g toluene, stirred until fully dissolved to form a solution, The solution is a transparent conductive resin in a solution state provided by the present invention. That is, 32 parts by mass of the transparent matrix resin, 6 parts by mass of organic acid-doped polyaniline, 3 parts by mass of the crosslinking monomer, 0.1 parts by mass of the curing initiator, and 60 parts by mass of toluene.

Embodiment 2

[0040]50g epoxy acrylate resin, 1g dodecylbenzenesulfonic acid doped polyaniline, 15g pentaerythritol tetraacrylate, 1g azo thermal initiator (such as azobisisobutyronitrile), 90g toluene, mix uniformly to obtain Transparent conductive resin solution. That is, 50 parts by mass of the transparent matrix resin, 1 part by mass of organic acid-doped polyaniline, 15 parts by mass of the crosslinking monomer, 1 part by mass of the curing initiator, and 90 parts by mass of toluene.

Embodiment 3

[0042] 10g of polyurethane acrylate resin, 20g of camphorsulfonic acid-doped polyaniline, 1g of pentaerythritol tetraacrylate, 0.1g of azo thermal initiator (such as azobisisobutyronitrile), and 40g of toluene were uniformly mixed to obtain a transparent conductive resin solution. That is, 10 parts by mass of the transparent matrix resin, 20 parts by mass of organic acid-doped polyaniline, 1 part by mass of the crosslinking monomer, 0.1 parts by mass of the curing initiator, and 40 parts by mass of toluene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com