A metal oxide semiconductor P-N junction schootky diode structure and the production method thereof

An oxide semiconductor, P-N technology, used in semiconductor/solid-state device manufacturing, transistors, electrical components, etc., can solve problems such as high forward voltage drop, low reverse leakage current, and low forward voltage drop. , to achieve the effect of low forward voltage drop, low leakage current, and small reverse bias leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

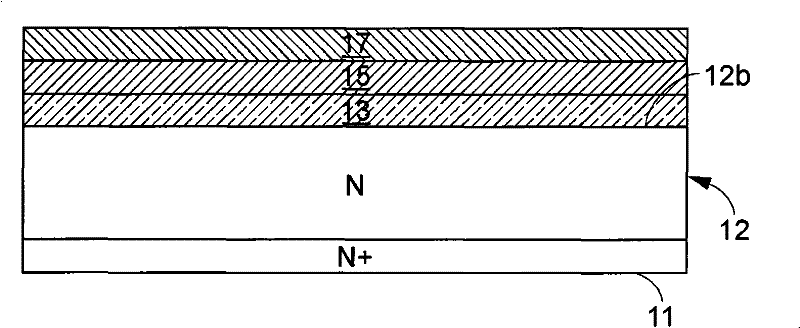

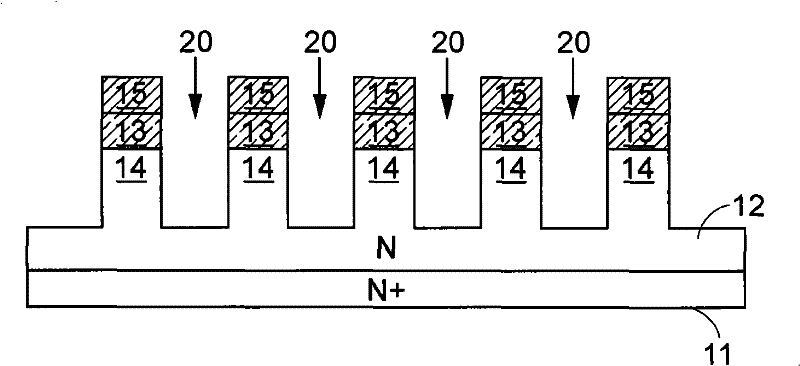

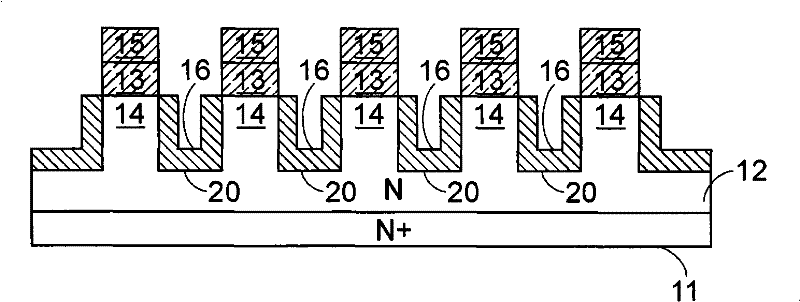

[0034] See figure 2, which is a schematic diagram of a preferred embodiment of a metal oxide semiconductor P-N junction Schottky diode structure developed by the present invention to improve the shortcomings of known technical means. We can clearly see from the figure that the metal oxide semiconductor P-N junction Schottky diode 2 structure mainly includes a substrate 21, a trench structure 22, a gate structure 23, a sidewall structure 24, a metal layer 25 and an ion Implantation region 26, wherein the substrate 21 is composed of a high doping concentration N-type silicon substrate (N+ silicon substrate) 211 and a low doping concentration N-type epitaxial layer (N- epitaxial layer) 212, the trench structure 22 is formed in Above the substrate 21, the gate structure 23 is formed in the trench structure 22 and protrudes from the surface 2120 of the low-doped N-type epitaxial layer 212, and the sidewall structure 24 is formed on the surface of the substrate 21 and located on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com