Method for dispersing higher fatty alcohol mixture

A technology for higher fatty alcohols and mixtures, applied in foam dispersion/prevention, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of not easy to purchase, high price, and high raw material price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

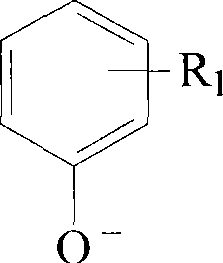

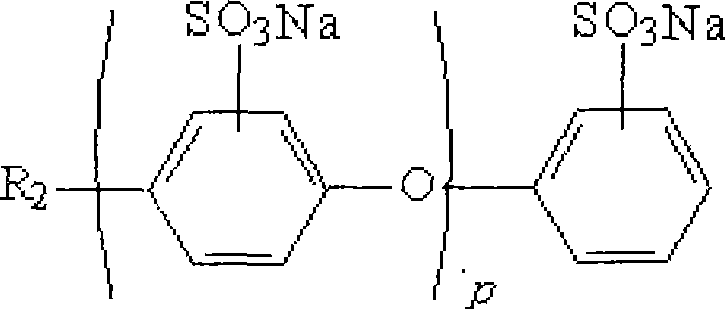

Image

Examples

Embodiment 1

[0037] 150 parts of synthetic fatty alcohol, 80 parts of natural C14-16 fatty alcohol, 70 parts of solid paraffin, 9 parts of n-octanol polyoxyethylene ether (30), 6 parts of sodium cetyl diphenyl ether disulfonate, dodecane 6 parts of sodium base sulfate, mix and melt the above raw materials, stir and heat up to 85°C, slowly add 320 parts of water at 70°C to the above mixture, then let the above coarse emulsion pass through the colloid mill to the required particle size, and finally cool down to 35°C, and diluted with 430 parts of tap water to form a 30% emulsion, adding an acrylic thickener to adjust the viscosity of the emulsion to 430mPa·s.

Embodiment 2

[0039] 304 parts of synthetic fatty alcohol, 160 parts of natural stearyl alcohol, 180 parts of solid paraffin, 30 parts of n-octyl alcohol polyoxyethylene ether (40), 36 parts of sodium dodecylbenzenesulfonate, lauryl ether polyoxyethylene ether (6 ) 20 parts of sodium sulfate, mix and melt the above raw materials, stir and heat up to 90°C, slowly add 600 parts of water at 80°C to the above mixture, then let the above coarse emulsion pass through the colloid mill to the required particle size, and finally cool down to 40 ℃, and diluted with 1650 parts of tap water to a 20% emulsion, adding an acrylic thickener to adjust the viscosity of the emulsion to 460mPa·s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com