Carbon-based supercapacitor based on polyacrylamide gel electrolyte and preparation method thereof

A polyacrylamide gel, supercapacitor technology, applied in electrolytic capacitors, capacitors, capacitor parts and other directions, can solve the problems of complex carbon aerogel synthesis process, high cost, small capacity, etc., and achieve good electrochemical capacitor performance. , the effect of wide window voltage range and high specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

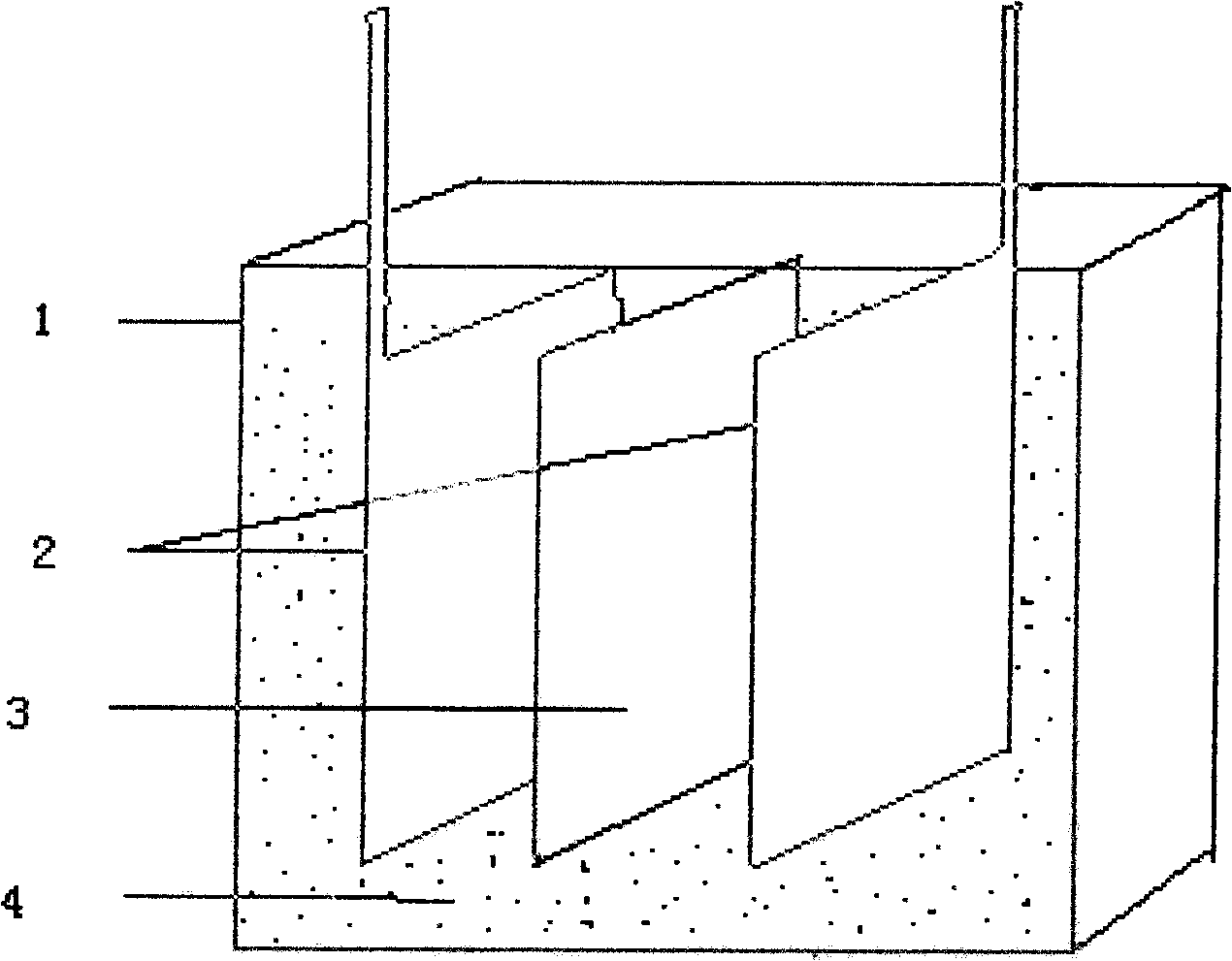

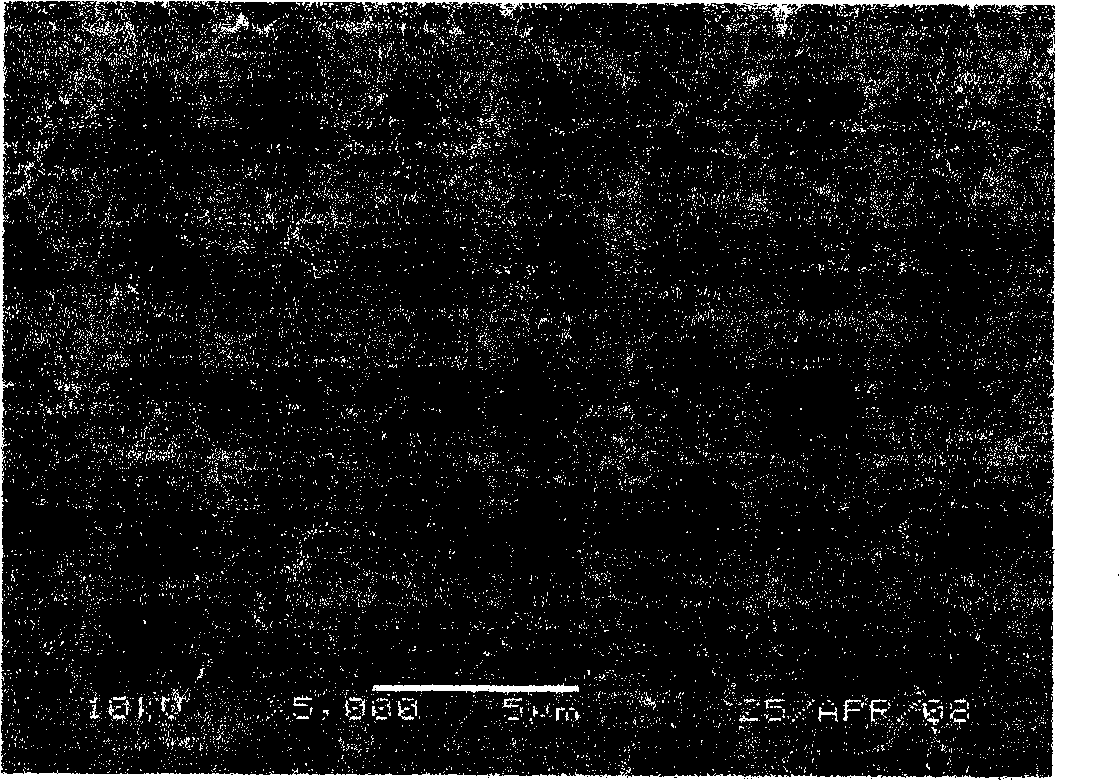

[0024] Preparation of carbon nanotube-carbon fiber composite electrode: Polish the nickel sheet with sandpaper, and then pretreat it with ultrasonic waves in acetone and water for 10 minutes respectively; then use low-pressure chemical vapor deposition equipment to grow carbon nanotube-carbon fiber film on the nickel sheet, The hydrogen flow rate is 100sccm and 50sccm respectively, the growth temperature is 550°C, and the growth time is 30 minutes. The nickel sheet with the carbon nanotube-carbon fiber film grown on it is used as the electrode of the supercapacitor, and its morphology is as follows figure 2 As shown, the carbon nanotubes and carbon fibers are intertwined to form a network structure, the density distribution is uniform, and the tube diameter is about 20-50nm;

[0025] The preparation process of polyacrylamide gel electrolyte and supercapacitor is as follows:

[0026] (1) Put the carbon nanotube-carbon fiber film electrode 2 into the polyvinyl alcohol PVA capac...

Embodiment 2

[0036] Preparation of carbon nanotube-carbon fiber composite electrode: After wiping the graphite sheet with water, acetone, and ethanol, pretreatment is carried out by drying at 70°C for 20 minutes to ensure that water and organic solvents do not remain; After sputtering a 20nm nickel catalyst on the graphite sheet by sputtering, the carbon nanotube-carbon fiber film was grown on the graphite sheet by low-pressure chemical vapor deposition equipment. During the growth, the flow rates of acetylene and hydrogen were 100 sccm and 100 sccm respectively, and the growth temperature was 550°C. The growth time is 30 minutes, and the graphite substrate after growing carbon nanotubes-carbon fibers is used as an electrode, and its morphology is as follows Figure 5 As shown, the carbon nanotubes and carbon fibers are intertwined to form a network structure, the density distribution is uniform, and the tube diameter is about 40-100nm.

[0037] The preparation process of polyacrylamide ge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com