Modification method for improving compatibility and interface associativity of polylactic acid/starch blend

A starch blend and interfacial combination technology, which is applied in the direction of tubular objects, other household appliances, flat products, etc., can solve the problems of low mechanical and thermal properties, poor dispersion, and poor compatibility of polylactic acid/starch blends , to achieve good biodegradability, low cost, and improved mechanical and thermal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

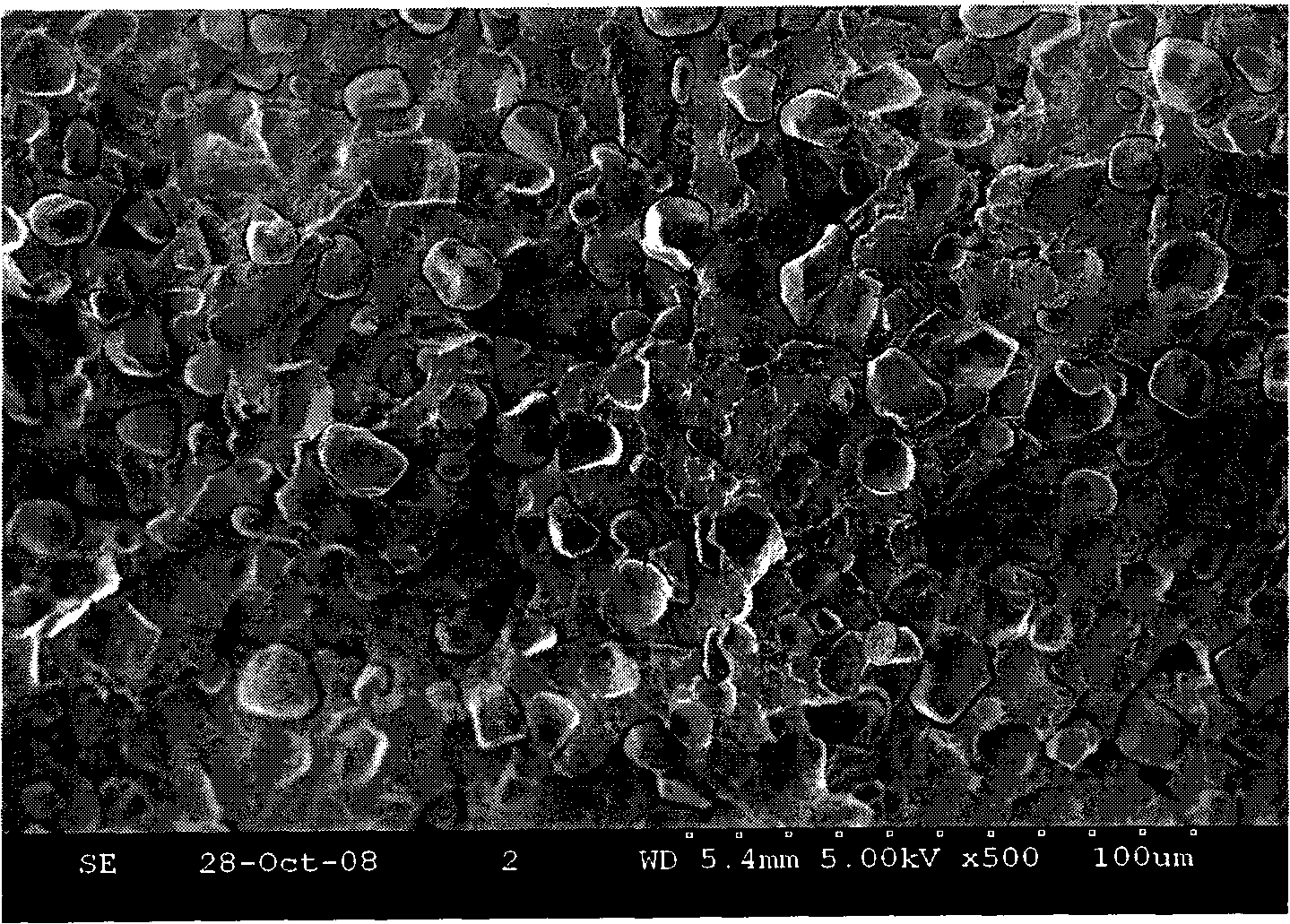

Embodiment 1

[0023] (1) Starch and polypropylene glycol (compatibilizer) were mixed for 10 minutes by a high-speed mixer at a mass ratio of 90:10;

[0024] (2) The above-mentioned powder and polylactic acid granules are extruded and granulated by twin-screw blending according to a certain mass ratio of 40:50, and the blending temperature is 150-230° C. to form polylactic acid / starch blended modified resin granules;

[0025] (3) The above granules are injection molded into standard splines by an injection molding machine. The mechanical properties were tested by impact strength tester and universal testing machine.

Embodiment 2

[0027] (1) Starch and polypropylene glycol (compatibilizer) are mixed by mass ratio 90:10 by high-speed kneader (500rpm) for 10 minutes;

[0028] (2) The above-mentioned powder, TDI (toluene diisocyanate) and polylactic acid particles are mixed in a low-speed mixer (50rpm) in a mass ratio of 40:50:1, and then extruded and granulated by twin-screw blending. The blending temperature 150-230°C to form polylactic acid / starch blended modified resin particles;

[0029] (3) The above granules are injection molded into standard splines by an injection molding machine. The mechanical properties were tested by impact strength tester and universal testing machine.

[0030] The results of Example 1 and 2 are compared as follows:

[0031]

[0032] As can be seen from the comparison table above, the tensile strength of the blend with only compatibilizer added is lower than PLA and PP, the elastic modulus is lower than PLA but higher than PP, and the flexural modulus is lower than PLA b...

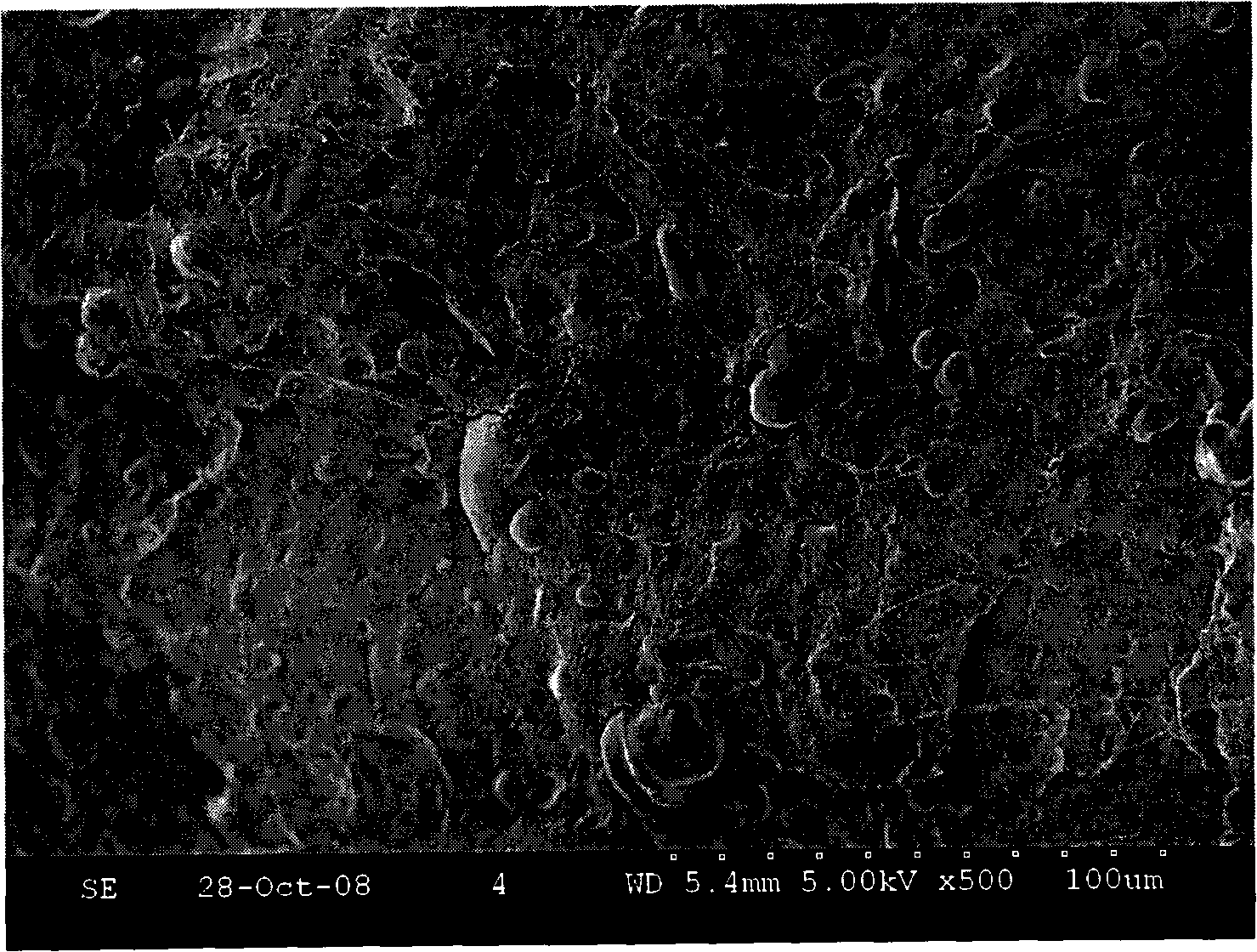

Embodiment 3

[0038] (1) Starch and polytetrahydrofuran (compatibilizer) were mixed for 15 minutes through a high-speed kneader (500rpm) at a mass ratio of 80:20;

[0039] (2) The above-mentioned powder, TDI and polylactic acid particles are mixed in a low-speed mixer (60rpm) at a mass ratio of 40:50:5, and are extruded and granulated by twin-screw blending. The blending temperature is 150-230°C, Form polylactic acid / starch blend modified resin particles;

[0040] (3) The above granules are injection molded into standard splines by an injection molding machine. The mechanical properties were tested by impact strength tester and universal testing machine.

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com