Gas drive membrane separation method and membrane separation device

A membrane separation and gas drive technology, which is applied in the field of fluid treatment and fluid separation, can solve the problems of continuous long-term operation of the membrane separation process, low cleaning efficiency, shortened service life, etc., to achieve continuous and stable operation, Effect of reducing membrane fouling and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

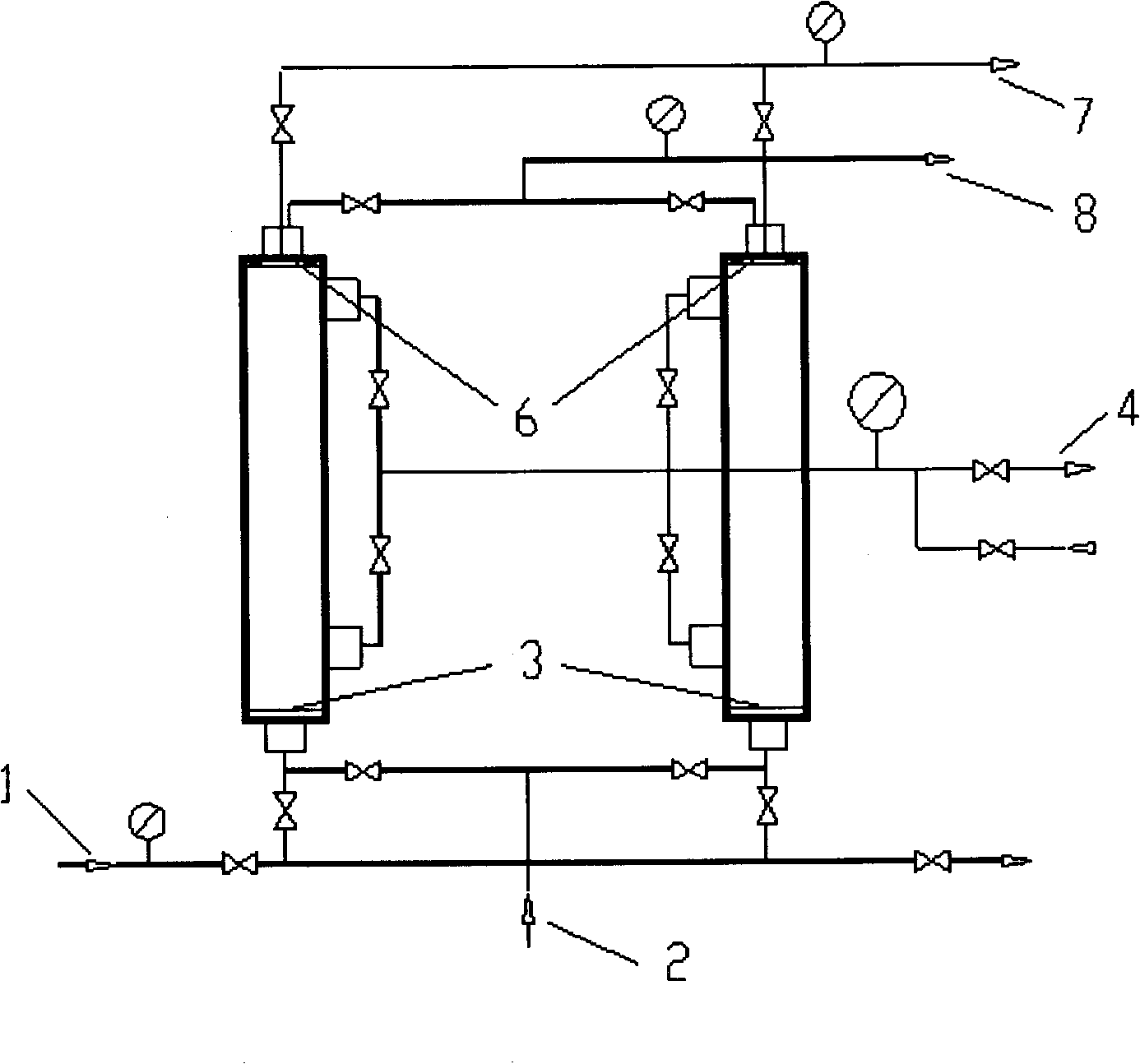

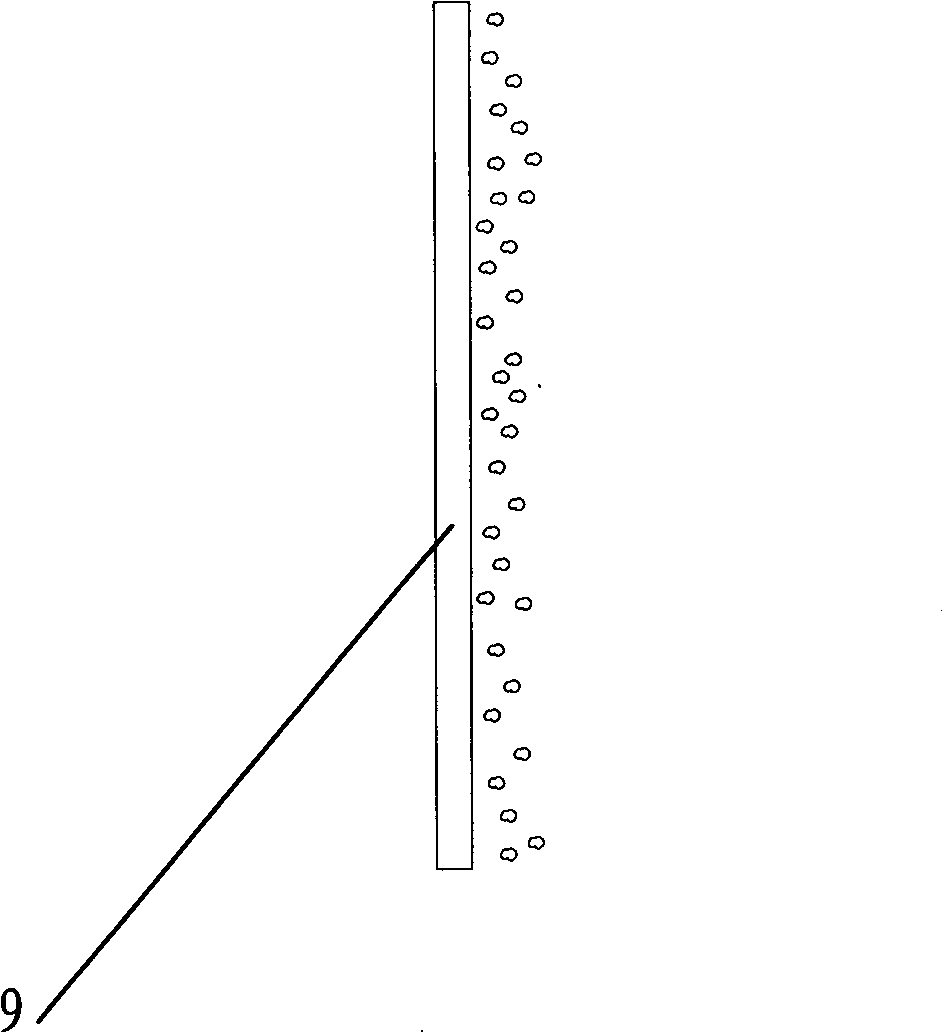

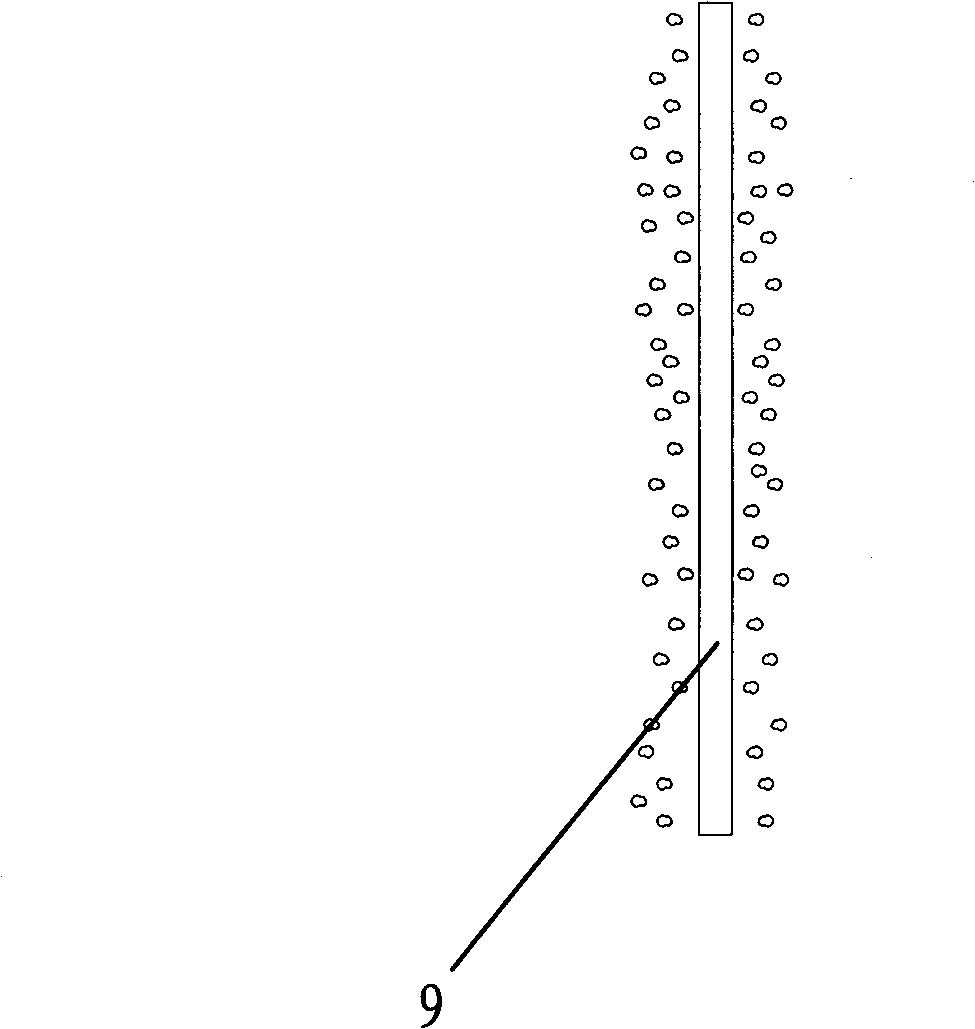

[0032] See figure 1 As shown, the main body of the membrane separation device 100 in the embodiment of the present invention is a hollow fiber membrane module 10, a hollow fiber membrane 11 is arranged in the hollow fiber membrane module 10, and a bubble generator is arranged at the bottom of the hollow fiber membrane module 10 3. The compressed air inlet 2 is connected to the bubble generator 3, and another bubble control device (not shown) is connected to the bubble generator 3 to control the bubble generator 3. The top of the hollow fiber membrane module 10 is also provided with a gas-water separator 6 connected to the gas-water separator is an exhaust port 7 .

[0033] The above-mentioned membrane separation device 100 is operated in this way. When the sewage enters the pipeline from the sewage inlet 1, it first enters the hollow fiber membrane module 10 from the bottom of the hollow fiber membrane module 10, and at the same time, the compressed air enters the bubble gene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com