Wool shrinkproof mercerization method

A mercerizing and wool technology, applied in the field of wool processing, can solve the problems of poor dyeing performance, uneven chlorination penetration of wool fiber tissue, poor spinnability, etc., to extend the wearing life, improve dyeing stability, prevent Excellent shrinkage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

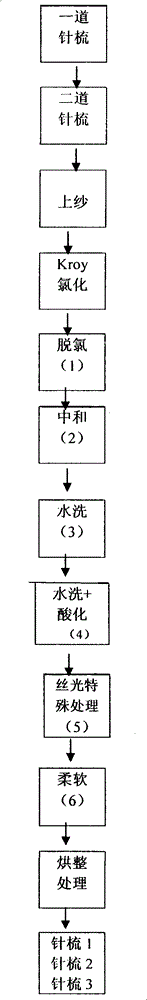

[0026] Such as figure 1 As shown, a kind of wool anti-shrinkage mercerizing treatment method described in this embodiment, its technical process is as follows:

[0027] 1. Add two needle combs to the front, and the first needle comb to card and open the wool and add a wetting agent for chemical pretreatment to ensure the uniformity of wool chlorination;

[0028] 2. In the second needle combing process, the wool is combed and mixed evenly. After 2 hours of storage, the additives sprayed in the first pass are fully reacted in the wool layer;

[0029] 3. Before entering the KROY equipment, the hair balls are unrolled into parallel strips to ensure that each wool top has no tension and no twist, and the chlorinated solution is sprayed on the wool at an even speed;

[0030] 4. The chlorination solution can be obtained by the action of chlorine gas and ice water to produce hypochlorous acid, and the surface of the wool fiber is uniformly chlorinated to eliminate fiber scales to ach...

Embodiment 2

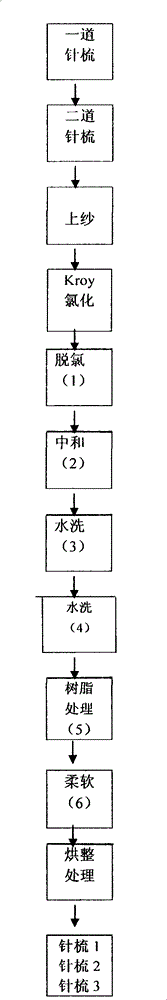

[0040] Such as figure 2 As shown, what this embodiment provides is that the new technology operation process of anti-shrinkage treatment is as follows:

[0041] 1. Add two needle combs to the wool sliver in the front, and the first needle comb to comb and loosen the wool and spray wetting agent for chemical pretreatment to ensure the uniformity of wool chlorination;

[0042] 2. In the second needle combing process, the wool is combed and mixed evenly. After 2 hours of storage, the wetting agent added in the first process is fully reacted in the wool layer;

[0043] 3. Before entering the KROY, the hair balls are unrolled into parallel strips to ensure that each wool top has no tension and no twist, and the chlorinated solution is sprayed on the wool at an even speed;

[0044] 4. The action of chlorine gas and ice water produces hypochlorous acid, which chlorinates the surface of wool fiber evenly, eliminates fiber scales and achieves a glossy effect. Add frequency conversio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com