Polycarbonate resin composition with superior appearance

A technology of polycarbonate resin and resin composition, applied in the field of polycarbonate resin composition and its molded products, can solve problems such as poor appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

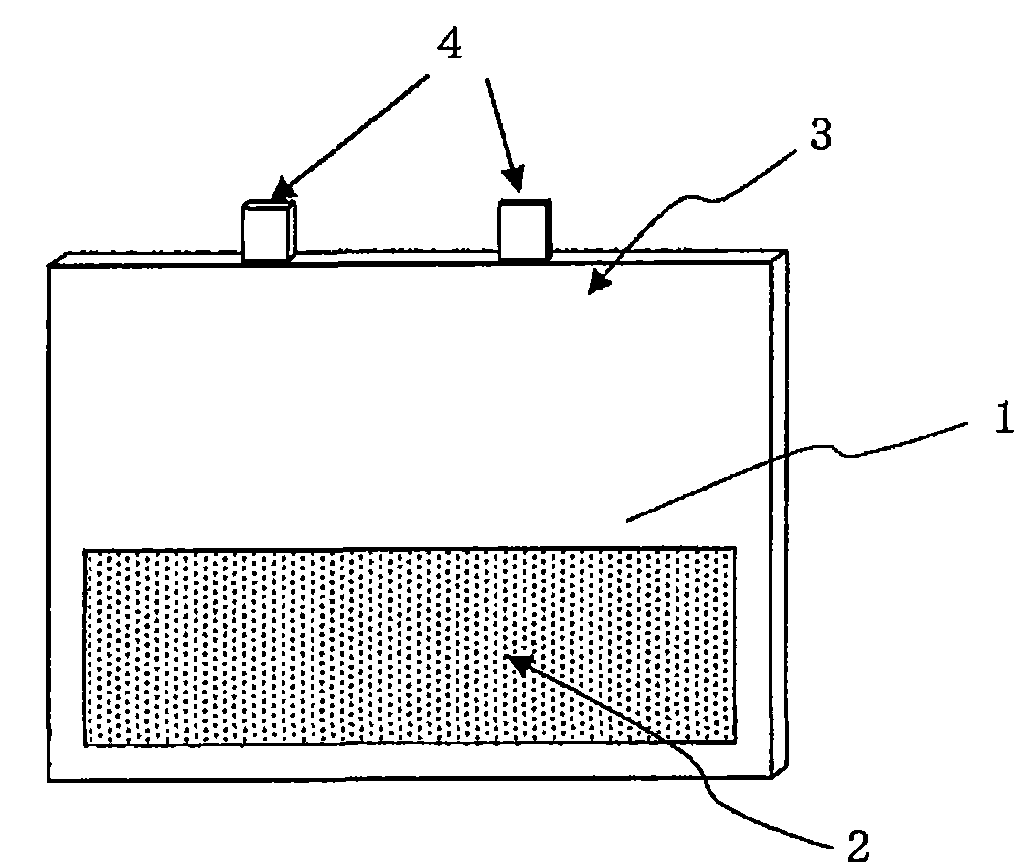

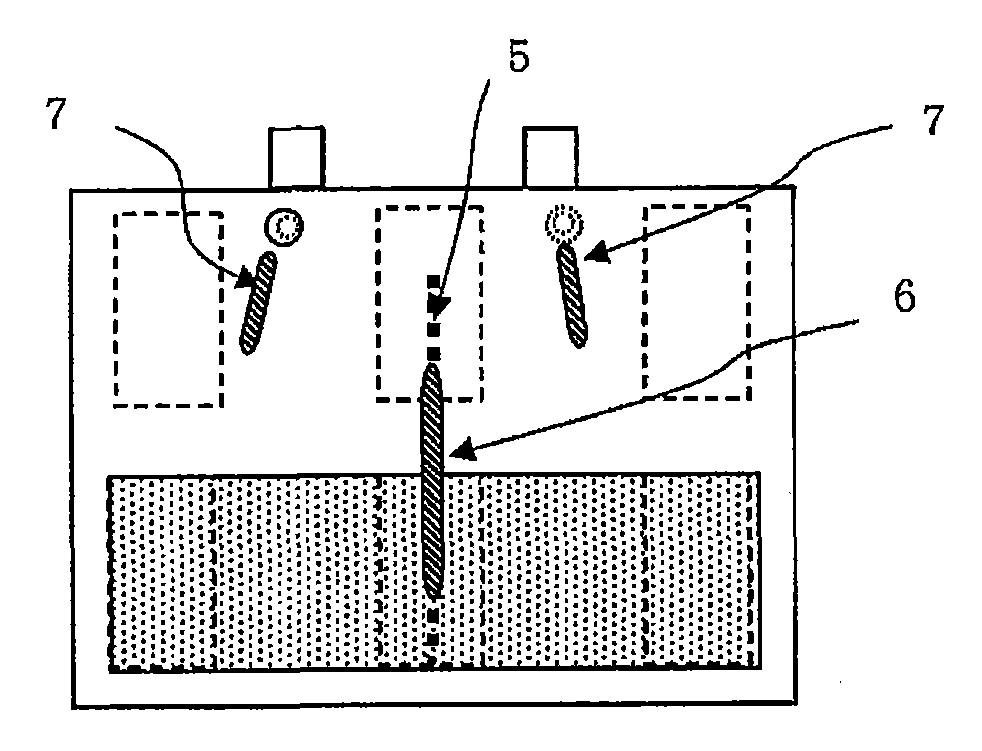

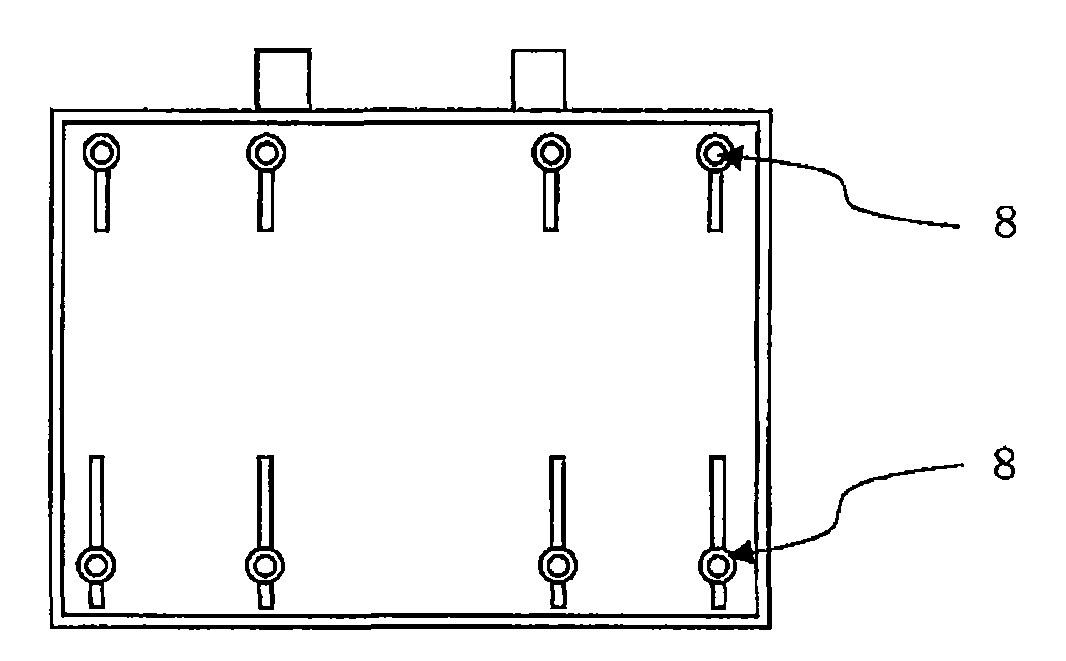

Image

Examples

Embodiment 1~19

[0246] Examples 1-19, Comparative Examples 1-10

[0247] According to the compositions shown in Table 1 to Table 3, the mixture is supplied from the first supply port of the extruder, and the mixture is composed of FR-1 (phosphate ester) except E component, D component (reinforcing filler) and B component (ABS- 1. Ingredients other than ABS-2, ABS-3, ABS-4). The mixture is obtained by mixing the following premix of (i) and other ingredients in a V-blender. That is, (i) is a mixture of component F (fluorine-containing anti-dripping agent) and an aromatic polycarbonate component A, wherein the components F and A are added so that the component F content becomes 2.5% by weight Put the mixture in a polyethylene bag and shake the bag as a whole to mix it evenly. When component B (ABS-1, ABS-2, ABS-3, ABS-4) and component D (reinforcing filler) are contained, use a side feeder and supply from the second supply port. Furthermore, when adding FR-1 of E component, in the state of he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com