Preparation method and application of stainless steel slag water-seepage and expansion cooling column

A technology of expansion cooling and stainless steel slag, which is applied to clay preparation devices, chemical instruments and methods, and manufacturing tools, and can solve the problems of large land occupation, serious pollution of the surrounding environment, and waste of water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with accompanying drawing:

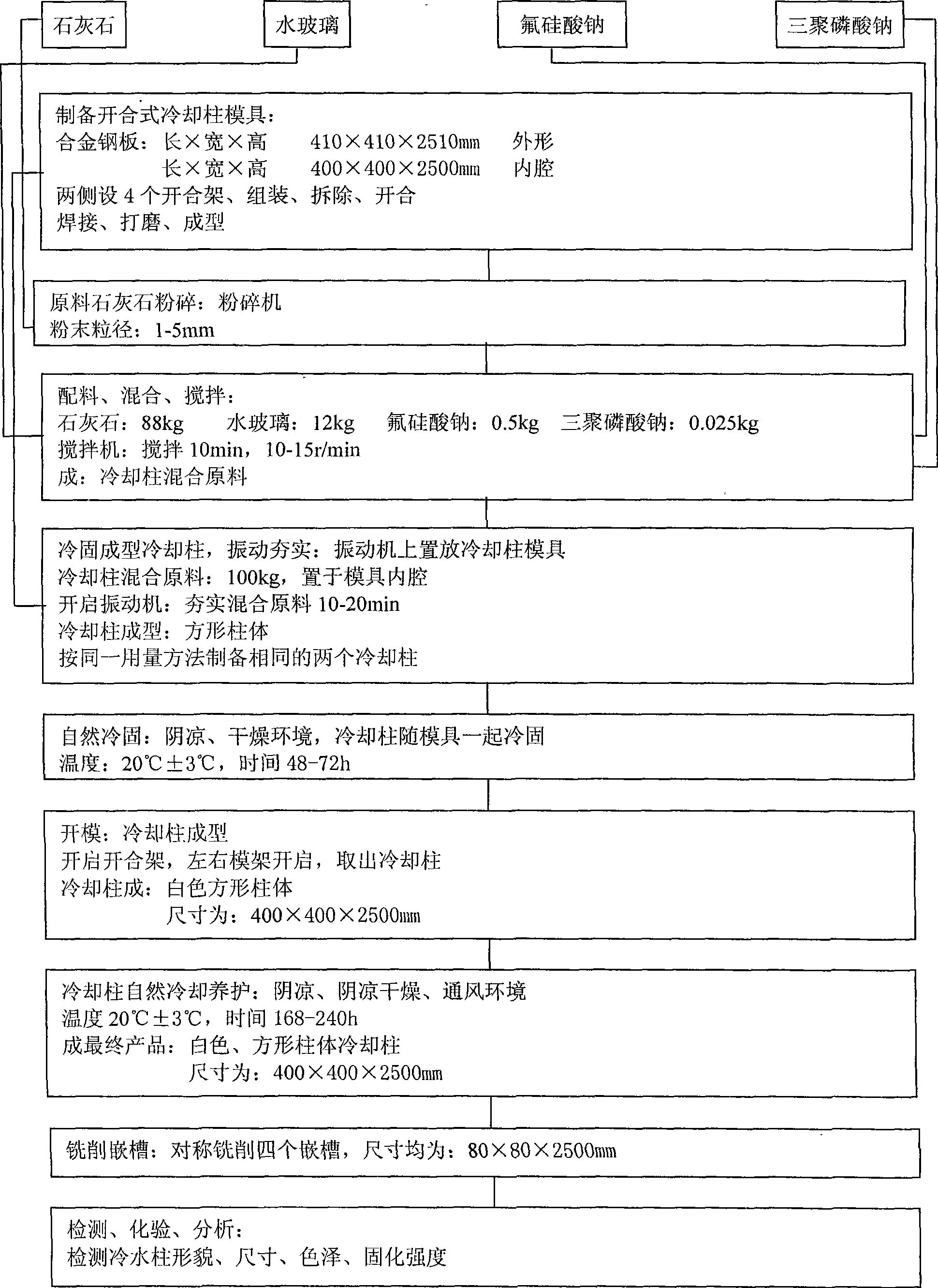

[0069] figure 1 Shown is the process flow chart for the preparation of stainless steel slag water seepage expansion cooling column.

[0070] The preparation of the water seepage expansion cooling column is calculated and designed based on the volume of a 32-ton stainless steel slag tank truck. The external dimensions and inner cavity volume are based on the 32-ton truck. is the unit of measurement.

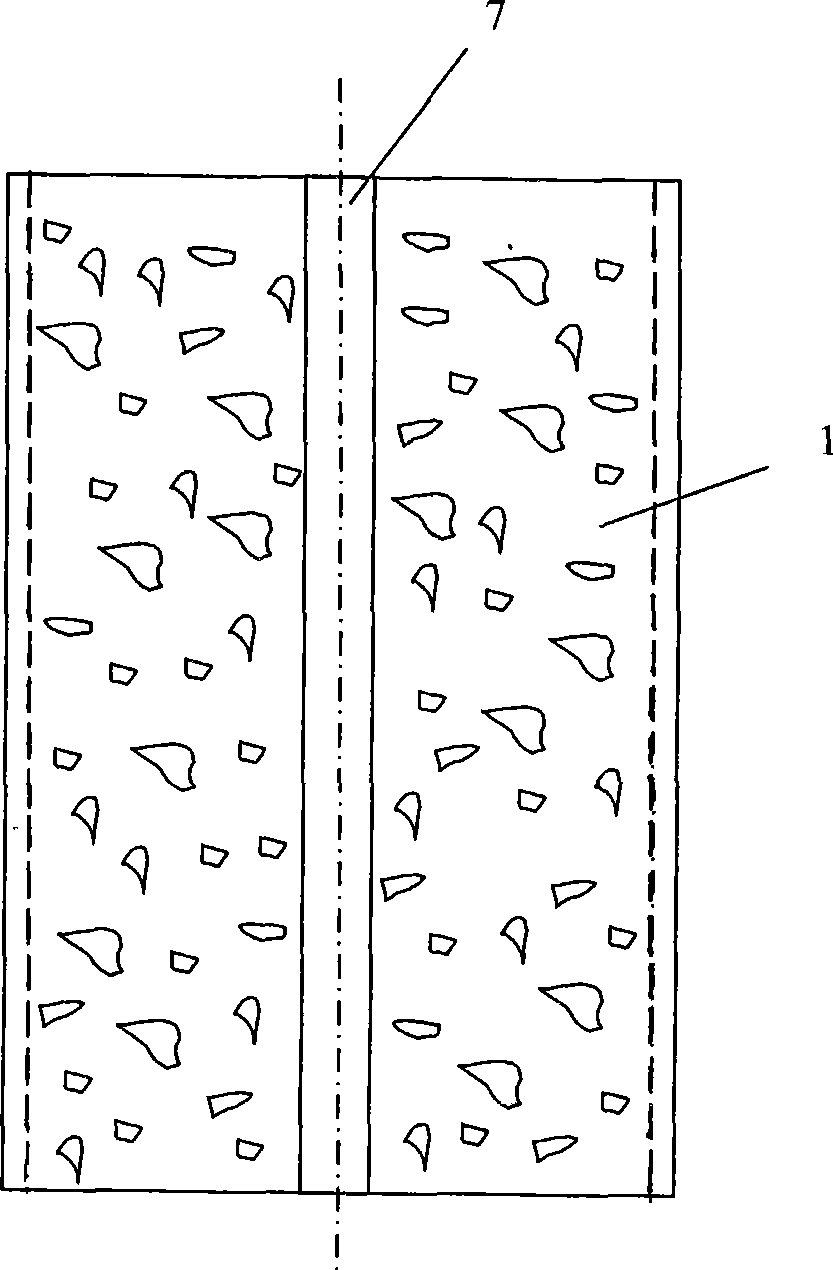

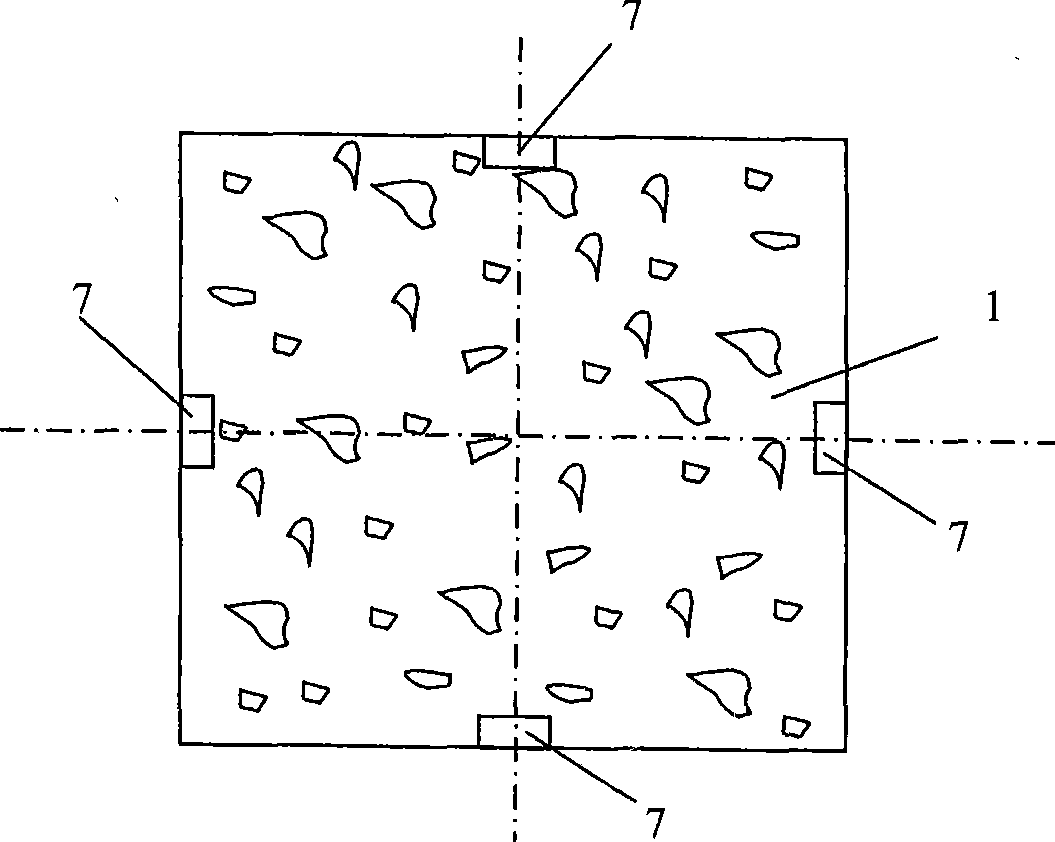

[0071] Prepare the cooling column mold first, then crush the limestone as the raw material of the cooling column, and the particle size of the powder is 1-5mm, then carry out batching, mixing, stirring, molding in the cooling column mold, and then vibrate and tamp, and finally make a square column The cooling column is naturally cooled and dried for 48-72 hours, then the mold is opened and demolded to form a cooling column, and then cooled in a cool and dry place for 168-240 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com