Crushing device and crushing method for preparing suspended polytetrafluoroethylene (PTFE) resin

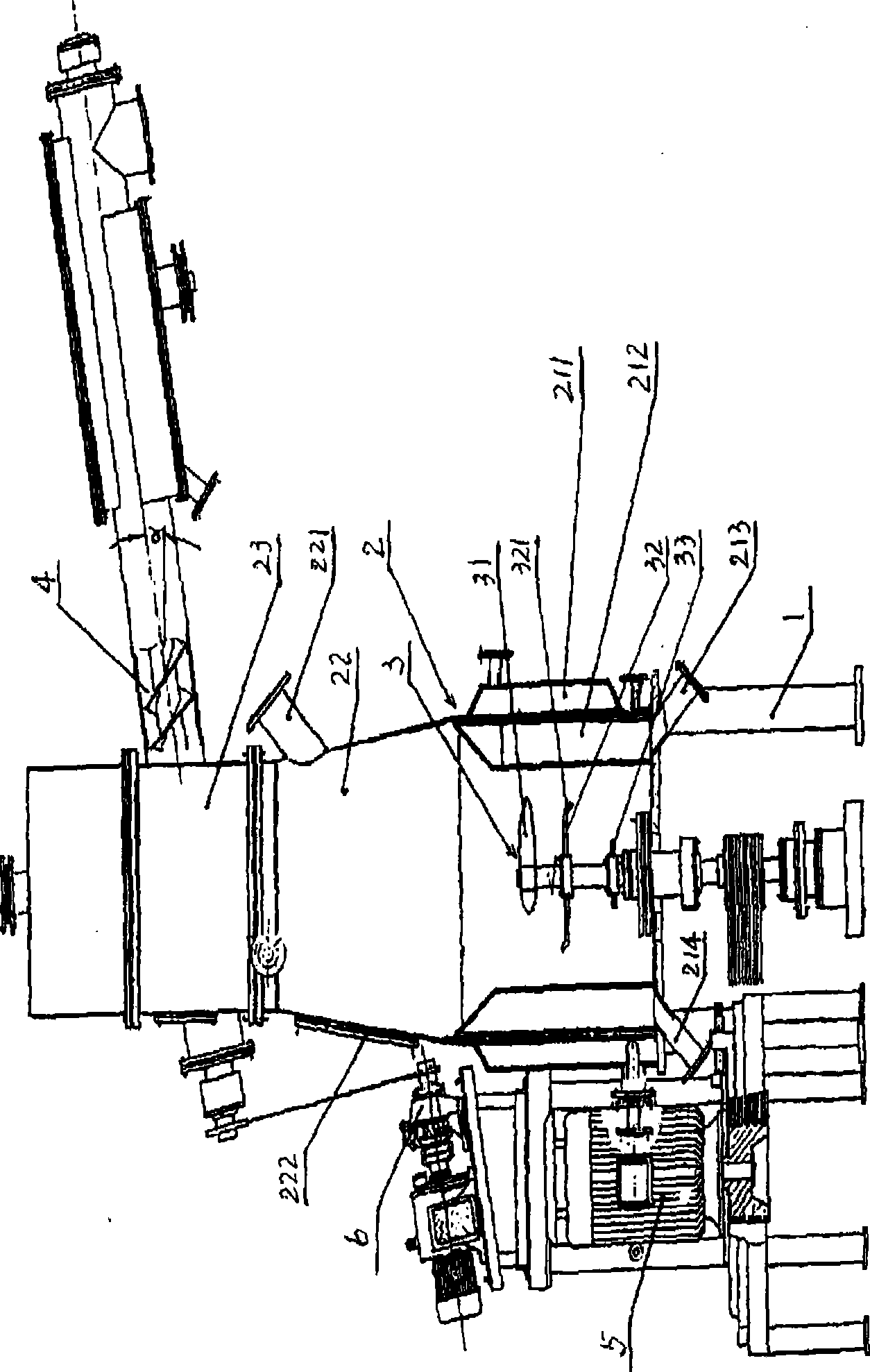

A technology of polytetrafluoroethylene and suspension method, which is applied in the direction of grain processing, etc., can solve the problems of complicated process equipment and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

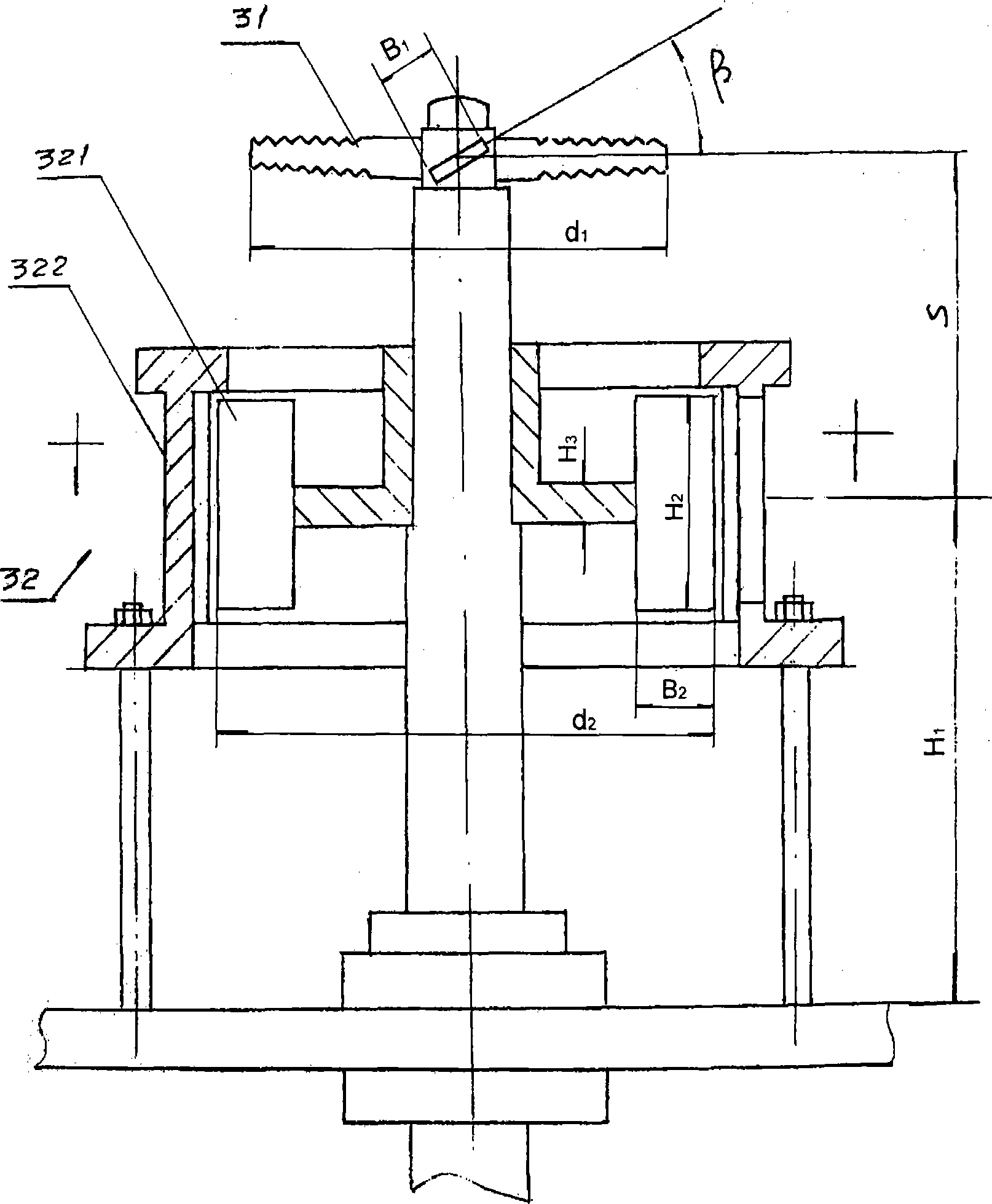

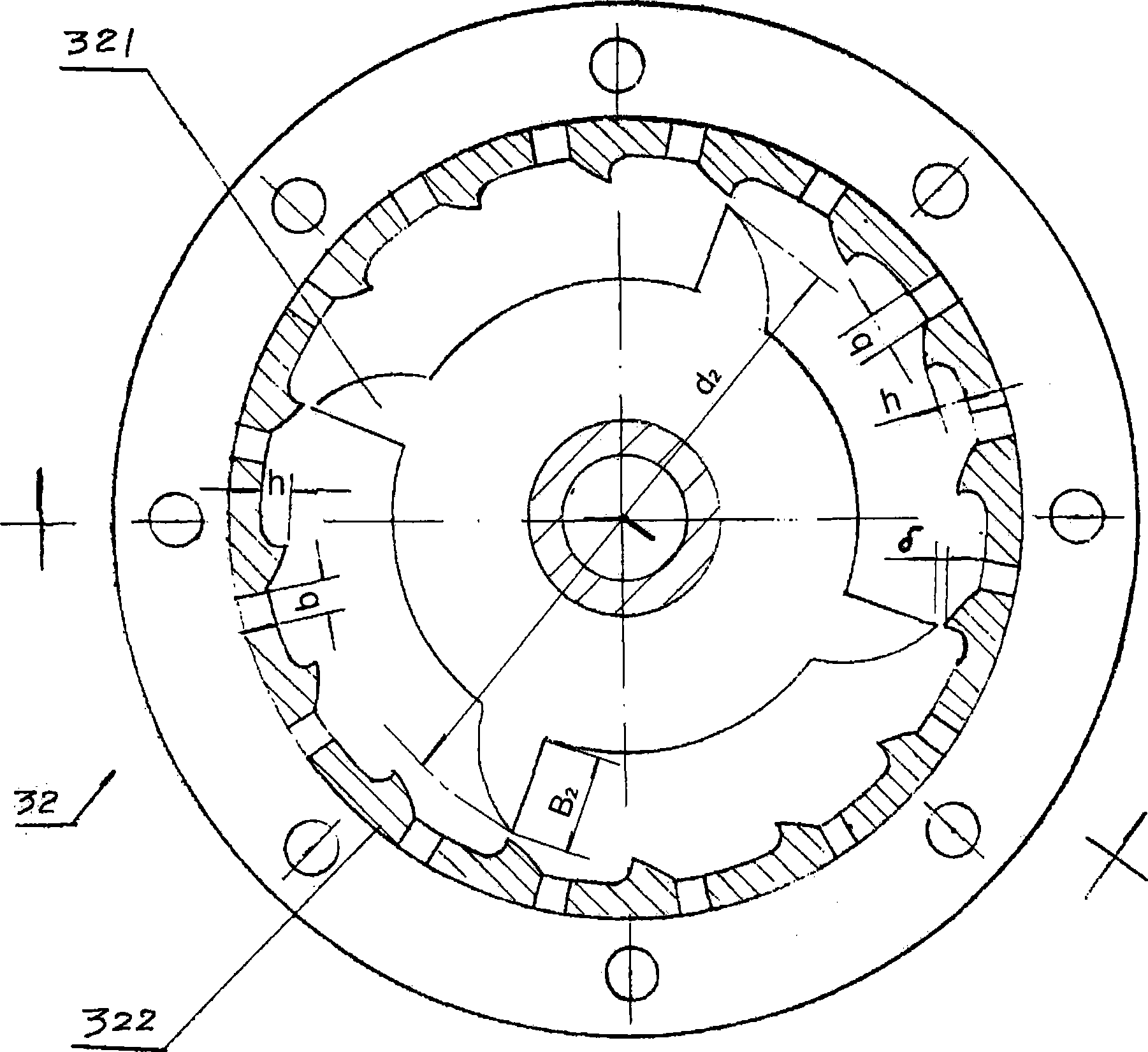

[0060] The polytetrafluoroethylene material and mother liquor after polymerization and high-pressure reaction enter the crushing barrel of the present invention through the discharge pipe, and most of the fibrous PTFE of about 5 mm and some agglomerated materials of about 80 mm sink at the bottom of the crushing barrel. Turn on the water pump, drain the mother liquor from the inlet and outlet pipes through the filter, stop the water pump, and add an appropriate amount of ion-free water so that the distance between the surface of the ion-free water and the oblique blades of the upper layer is 350mm. The height of the lower impingement blade in the bucket from the bottom of the barrel is 300mm, the distance between the beveled blade and the impacting blade is 250mm, the diameter of the beveled blade is φ350mm, the width of the beveled blade is 52mm, and the angle between the plane of the beveled blade and the horizontal plane is . The diameter of the rotary knife impacting the ...

Embodiment 2

[0062] The PTFE material and mother liquor after polymerization and high-pressure reaction enter the crushing barrel through the discharge pipe, and most of the fibrous PTFE of about 5mm and some agglomerated materials of about 80mm sink to the bottom of the crushing barrel. Turn on the water pump, drain the mother liquor from the inlet and outlet pipes through the filter, stop the water pump, and add an appropriate amount of ion-free water so that the distance between the surface of the ion-free water and the oblique blades of the upper layer is 350mm. The height of the impact paddle in the lower layer of the barrel from the bottom of the bucket is 300mm, the distance between the beveled blade and the impact blade is 250mm, the diameter of the beveled blade is φ350mm, the width of the beveled blade is 55mm, and the angle between the beveled blade and the horizontal plane is . The diameter of the rotary knife impacting the paddle is φ260mm, the rotary knife has 4 blades, the ...

Embodiment 3

[0064] The PTFE material and mother liquor after polymerization and high-pressure reaction enter the crushing barrel through the discharge pipe, and most of the fibrous PTFE of about 5mm and some agglomerated materials of about 80mm sink to the bottom of the crushing barrel. Turn on the water pump, drain the mother liquor from the inlet and outlet pipes through the filter, stop the water pump, and add an appropriate amount of ion-free water so that the distance between the surface of the ion-free water and the oblique blades of the upper layer is 450mm. The height of the impact paddle in the lower layer of the barrel from the bottom of the bucket is 300mm, the distance between the beveled blade and the impact blade is 250mm, the diameter of the beveled blade is φ370mm, the width of the beveled blade is 60mm, and the angle between the beveled blade and the horizontal plane is . The diameter of the rotary knife impacting the paddle is φ260mm, the rotary knife has 4 blades, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com