Amino multisection counterflow exhaust smoke processing device and method

A processing device and countercurrent technology, which is applied in the field of flue gas desulfurization devices, flue gas treatment or flue gas purification devices, can solve problems such as complex structure, easy waste of raw material ammonia, and difficult operation of desulfurization devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technology of the present invention will be described in more detail below with reference to the accompanying drawings for the flue gas of a coal-fired power generation boiler.

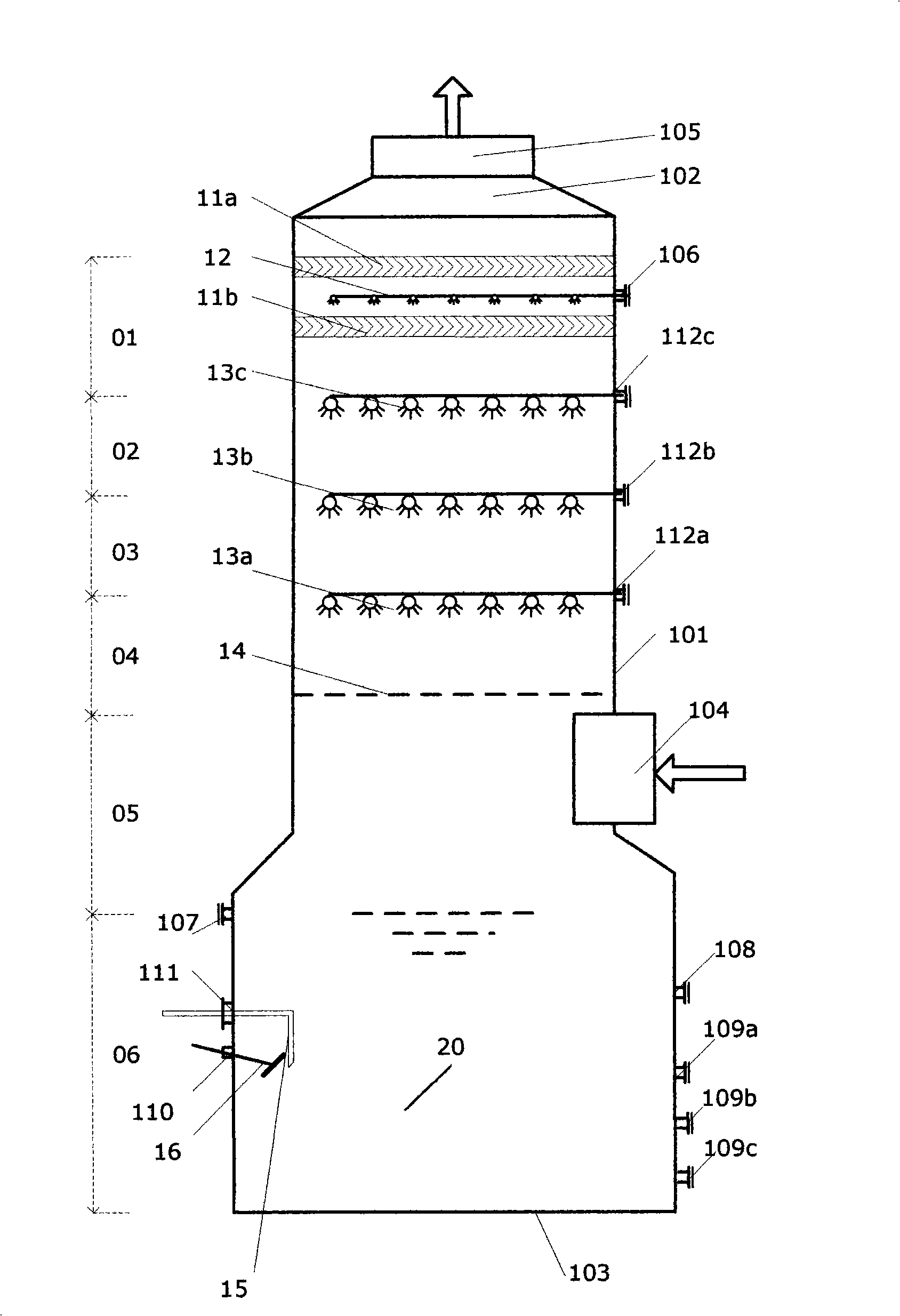

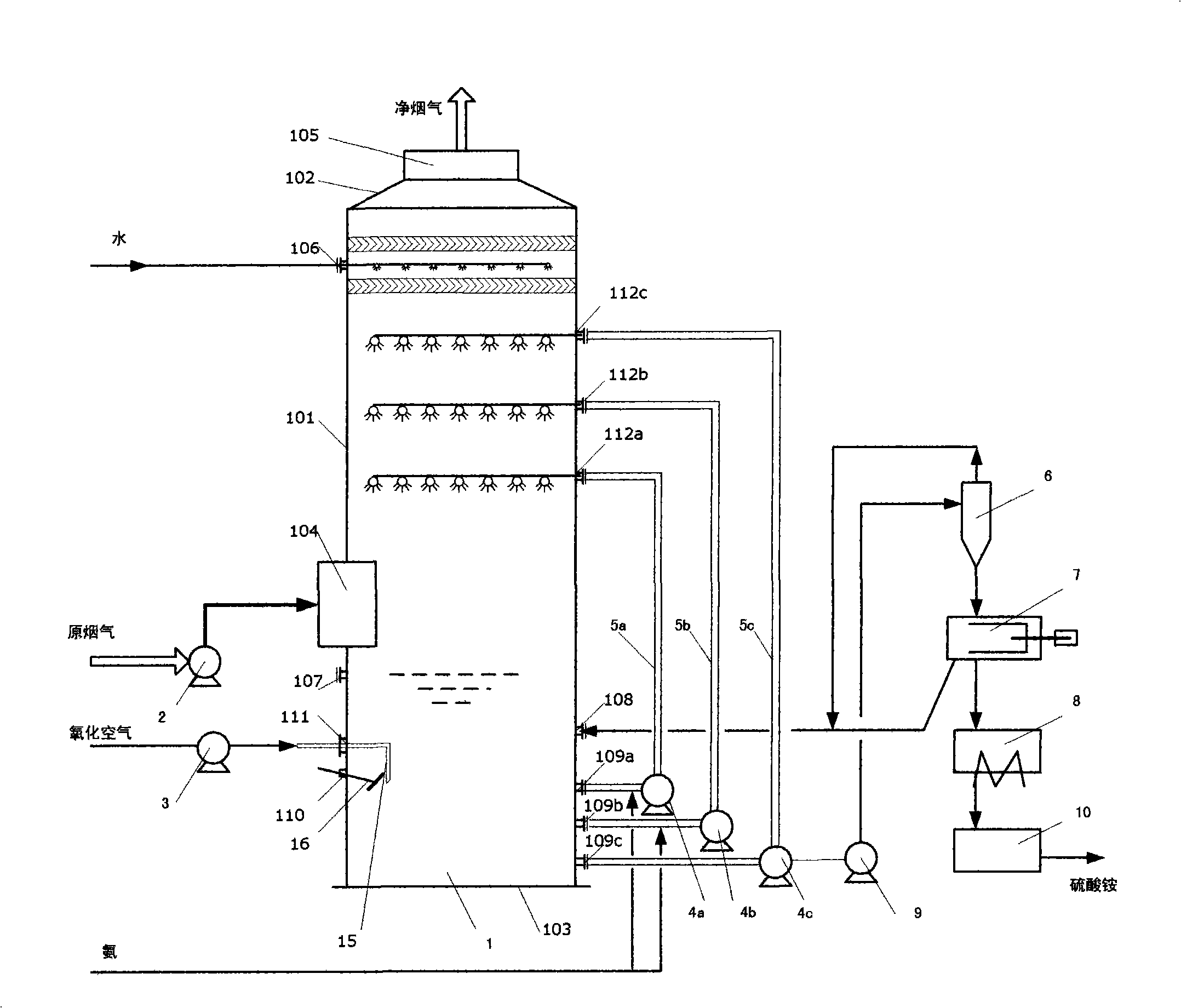

[0046] see figure 1 and figure 2 , an amino multi-stage countercurrent smoke exhaust treatment device of the present invention includes a desulfurization tower 1, and a flue gas outlet connecting pipe 105 is arranged on its top 102 or upper tower body 101; below the flue gas outlet connecting pipe 105, there are successively from top to bottom Gas-liquid separator 11, upper absorber 13c, middle absorber 13b, lower absorber 13a, flue gas homogenizer 14 and oxidizer 20, and flue gas is arranged between flue gas homogenizer 14 and oxidizer 20 Import takes over 104. Designed in this way, from the tower top 102 to the tower bottom 103, it is divided into gas-liquid separation section 01, deamination section 02, deamination and desulfurization section 03, desulfurization section 04, flue gas u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com