High-strength flame resistant magnesium alloy

A magnesium alloy, flame-retardant technology, applied in the field of high-strength flame-retardant magnesium alloy, can solve the problems of low absolute strength, easy to ignite, light weight, low cushioning properties, etc., and achieve the effect of high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

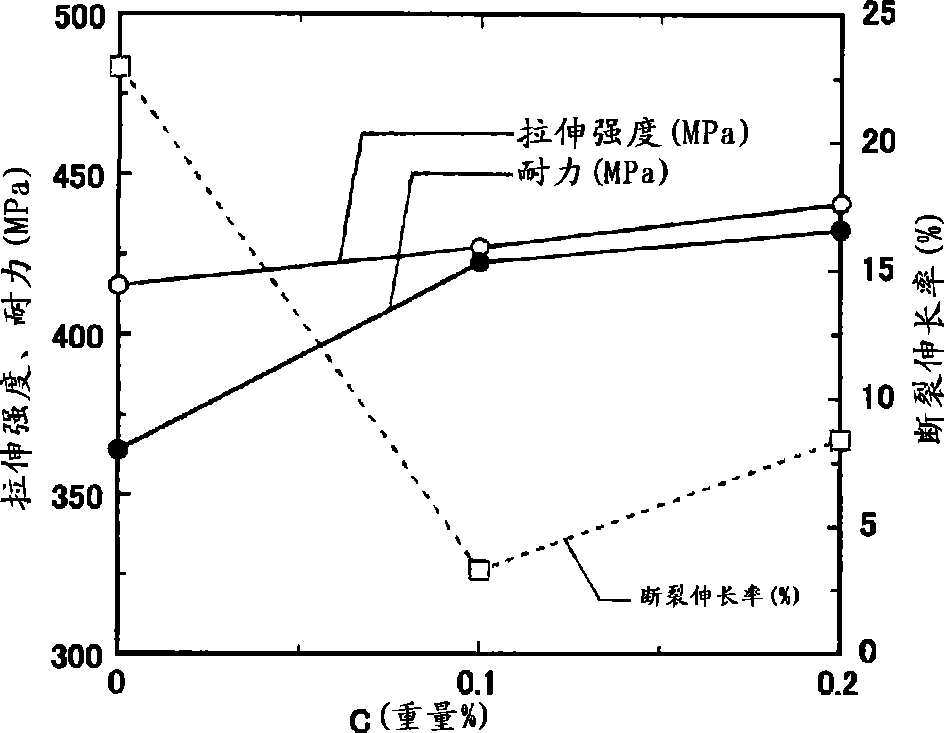

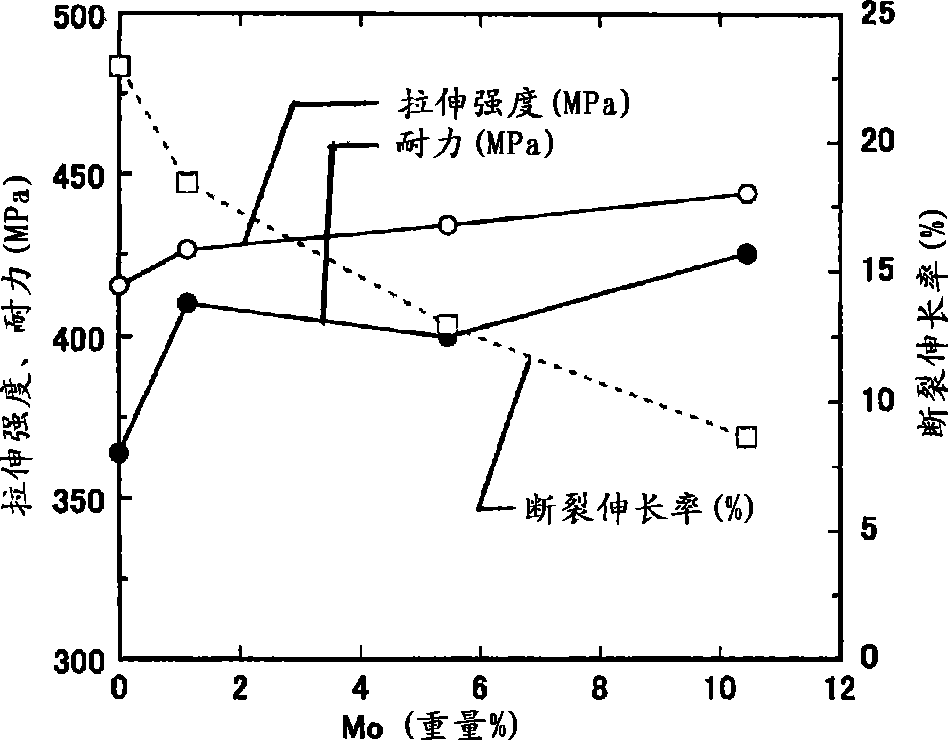

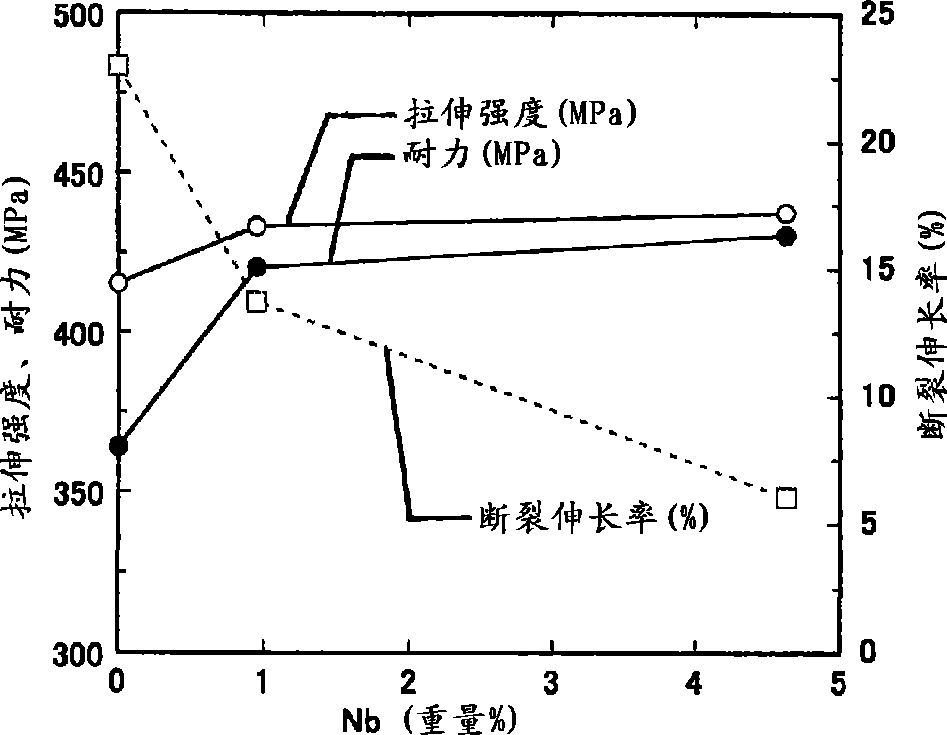

[0081] The alloy of this example is based on a flame-retardant magnesium alloy "AM60B+2Ca" to which 2.0% by mass of Ca is added to impart flame retardancy to the AM60B alloy. C, Mo, Nb, Si, W, Al were added as additional additives so as to achieve the composition shown in Table 1 2 o 3 , Mg 2 Si, SiC element or compound. In the present example, cutting chips belonging to turning chips were used as flake-like lumps of the alloy. The cutting chips were pulverized with a ball mill to obtain a pulverized product. At this time, additional additives are also added at the same time, and the additives are homogeneously dispersed and compounded.

[0082] Next, the pulverized material of the flame-retardant magnesium alloy prepared by the ball mill was solidified in the air at a sintering temperature of 480° C. for 20 minutes by a pulse current sintering method. Next, hot extrusion processing was performed using this as a billet at an extrusion ratio of 110 and an extrusion tempera...

Embodiment 2

[0097] This example shows that the Figure 1 to Figure 8 Joining results when the shown high-strength flame-retardant magnesium alloy is used as a welding wire of a solder for magnesium alloy welding. For the workpiece to be welded, an extruded sheet (2 mm in thickness) of a flame-retardant magnesium alloy "AM60B+2Ca alloy" to which 2% by mass of calcium was added to AM60B magnesium alloy for imparting flame retardancy was used. Welding by TIG method. The main welding conditions are as follows.

[0098] That is, a pure tungsten electrode with a diameter of 2.4mm is used, the distance between the electrode and the base metal is 2mm, the alternating current is 100A, the welding speed is 200mm / min, the inert gas is argon, and the flow rate is 12L / min. After welding, excess welding was removed to form a test piece shape, and a tensile strength test was performed to confirm the joint strength. This tensile strength test result is shown in table 3, Figure 9 and Figure 10 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com