Superimposition marker and method for producing the same

A manufacturing method and marking technology, which are used in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as defects in the active region, collapse of overlapping marks, etc., so as to avoid problems where the overlapping error value cannot be measured. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] To make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

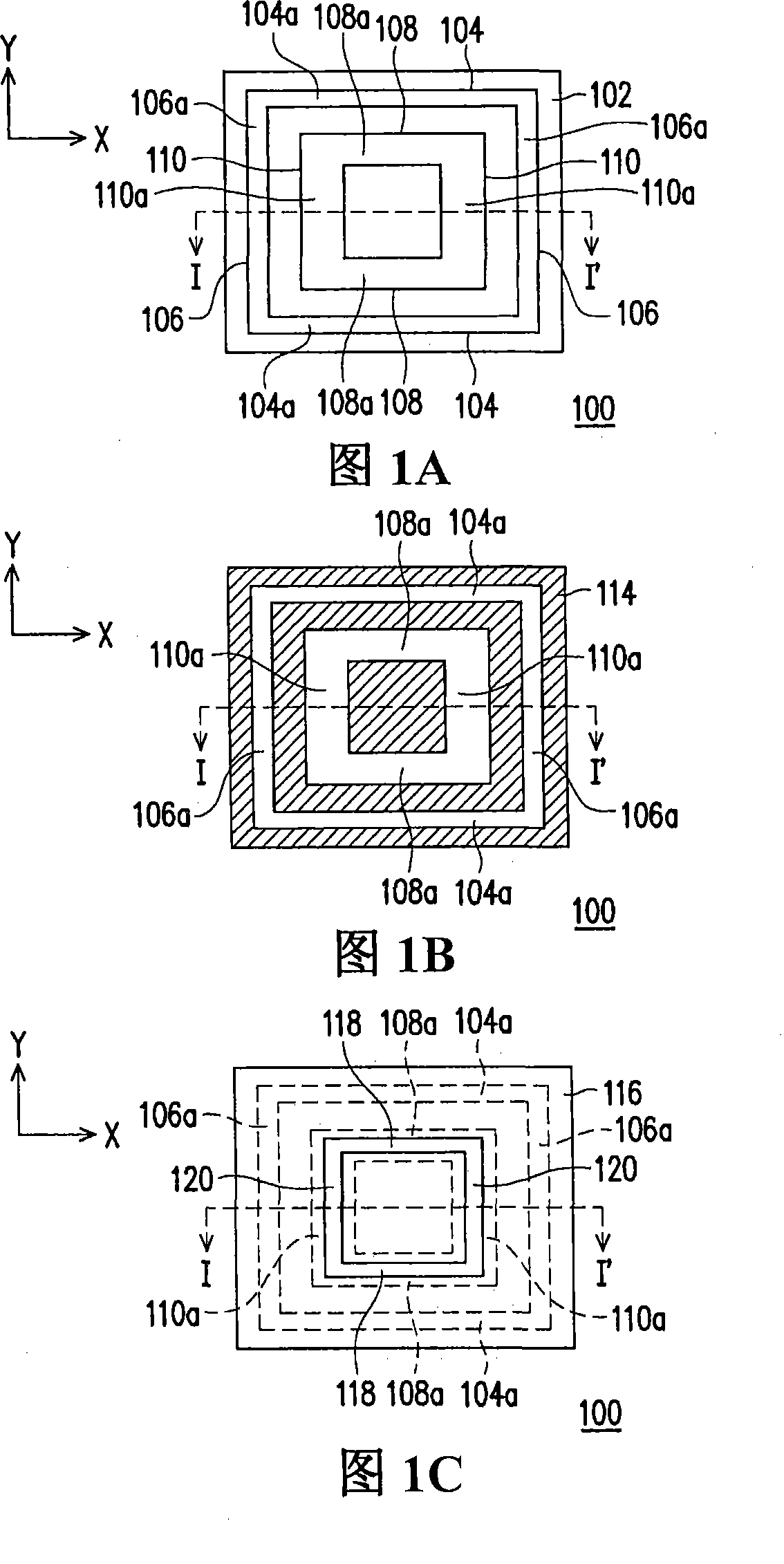

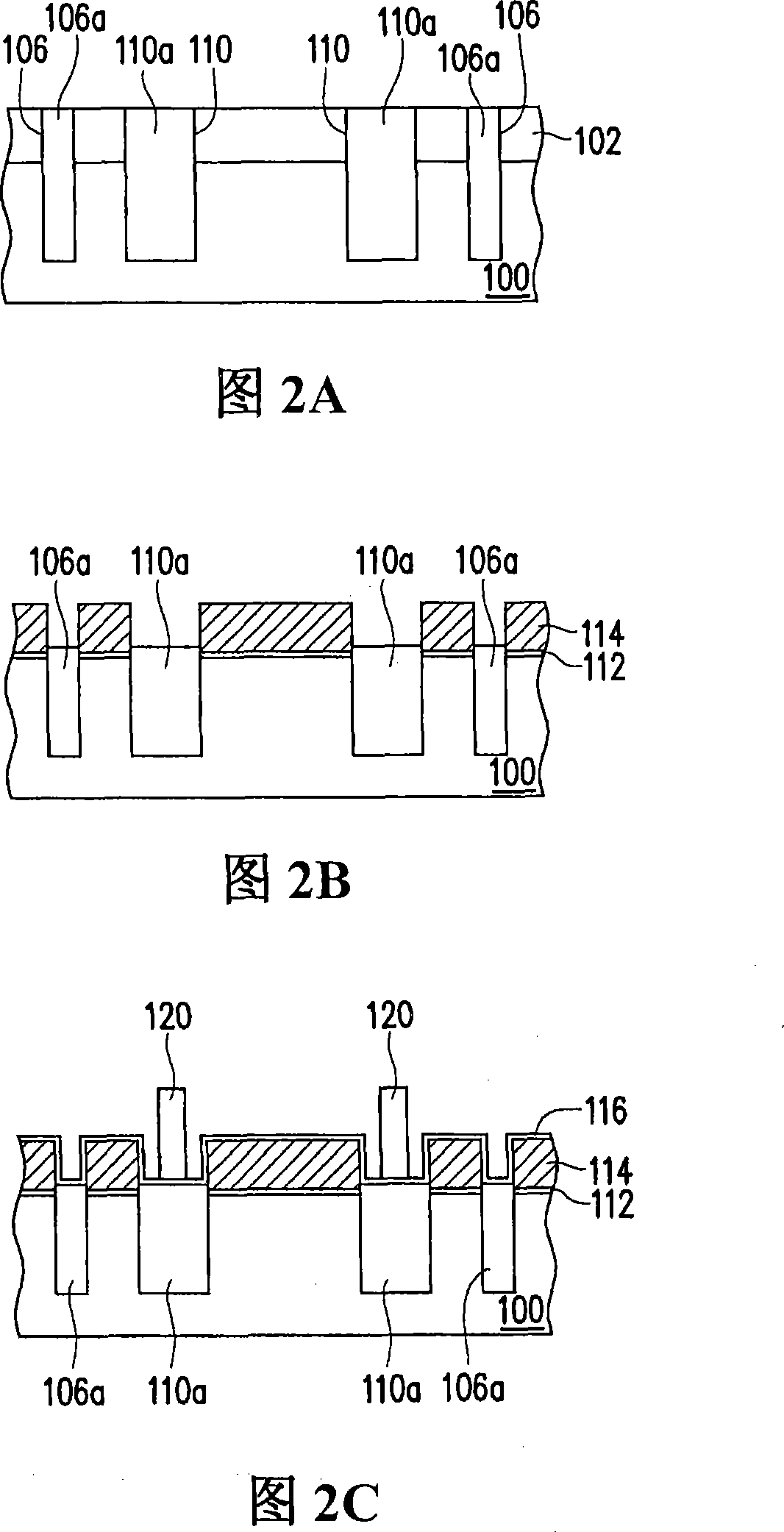

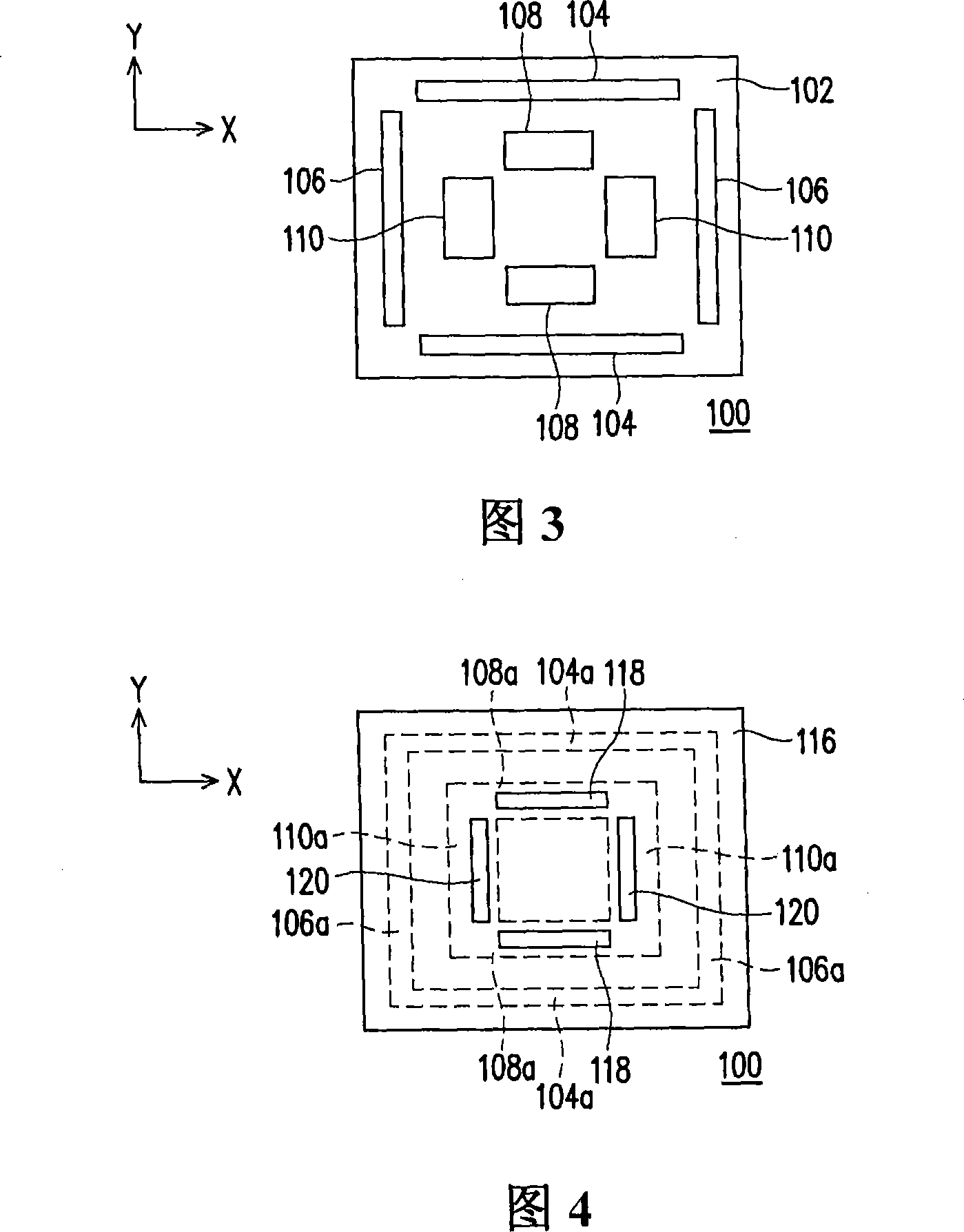

[0039] Figure 1A to Figure 1C It is a top view of the manufacturing process of the superposition mark according to the embodiment of the present invention. Figure 2A to Figure 2C According to Figure 1A to Figure 1C The cross-sectional view of the production process of the superimposed marker shown in the I-I section in . In particular, in the following description of the present invention, the film layers used to form the overlay mark in the peripheral area are all in the same process step as the film layers used to form the non-volatile memory in the component area. formed in.

[0040] First, referring to FIG. 1A and FIG. 2A simultaneously, a hard mask layer 102 is formed on the substrate 100 in the peripheral area. The substrate 100 is, for example, a silicon su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com