Grate production process for steel mill sintering apparatus

A production process and sintering equipment technology, applied in the production process of high-chromium heat-resistant castings, can solve the problems of loss of market competitiveness, long production cycle, energy consumption, etc., and achieve high-efficiency production, short production cycle, and fewer processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

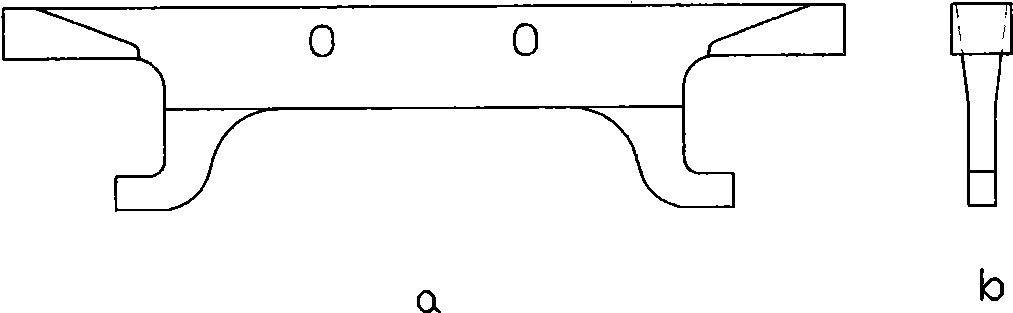

Image

Examples

Embodiment Construction

[0034] Fig. 3 has shown technological process of the present invention:

[0035] a) Mixed molding sand

[0036] After a large number of tests, we selected the following two kinds of raw sand and two kinds of modified water glass binders as the raw and auxiliary materials of the present invention, and carried out performance comparison tests to select raw materials with less binder addition and better strength properties. sand and binder.

[0037] Among them, raw sand index

[0038] Mud content (%): sea sand 0.40; quartz sand 0.34

[0039] SiO 2 Content (%): sea sand 97.8; quartz sand 98.9

[0040] The modified water glass binder is selected from the 433 and 466 water glass binders publicly sold by the Foundry Branch of Shanghai Machinery Manufacturing Technology Research Institute Co., Ltd., and its physical properties are shown in Table 1.

[0041] Table 1: Physical properties of two kinds of modified water glass binders

[0042] proportion Viscosity(20℃)m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com