Reinforced electric repair method of heavy metal polluted soil using anode liquor as eluant

A technology of polluted soil and electric restoration, applied in the restoration of polluted soil, etc., can solve the problem of blocking soil pores and achieve the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

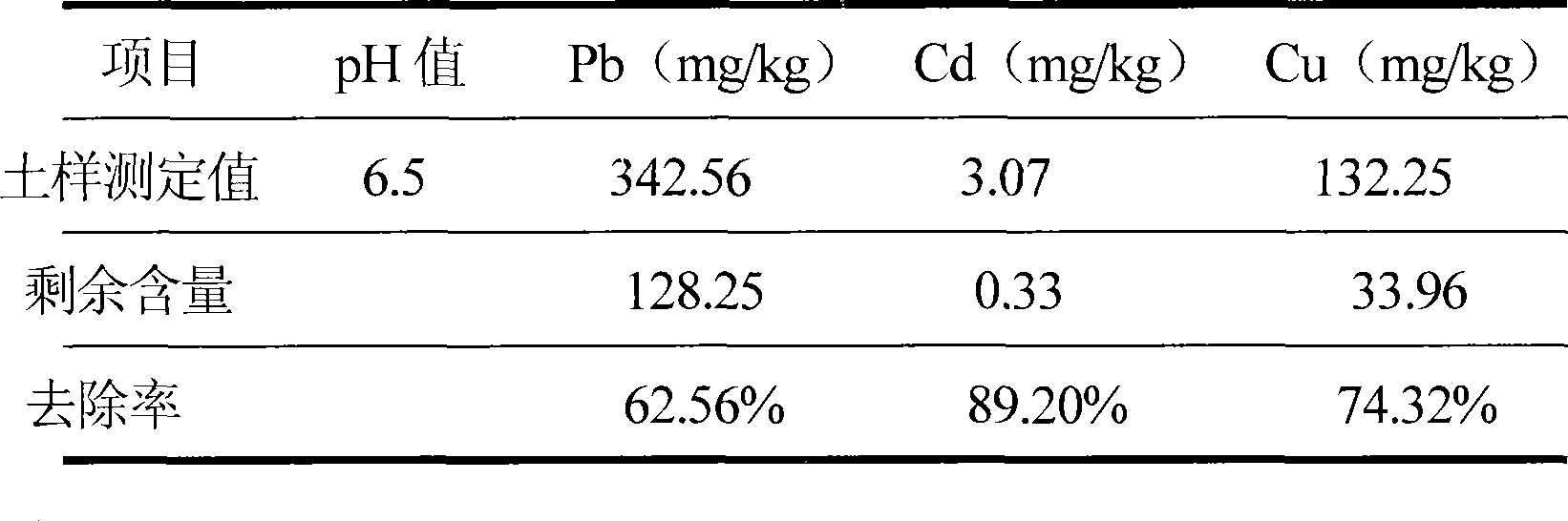

[0021] The experimental soil was collected from the abandoned lead-zinc mine in Lanping, Yunnan, with a buried depth of 0-30 cm. The soil samples were air-dried and passed through a 2mm sieve. The contents of heavy metals Pb, Cd, and Cu in the soil samples were determined by atomic absorption spectrophotometer, as shown in Table 1.

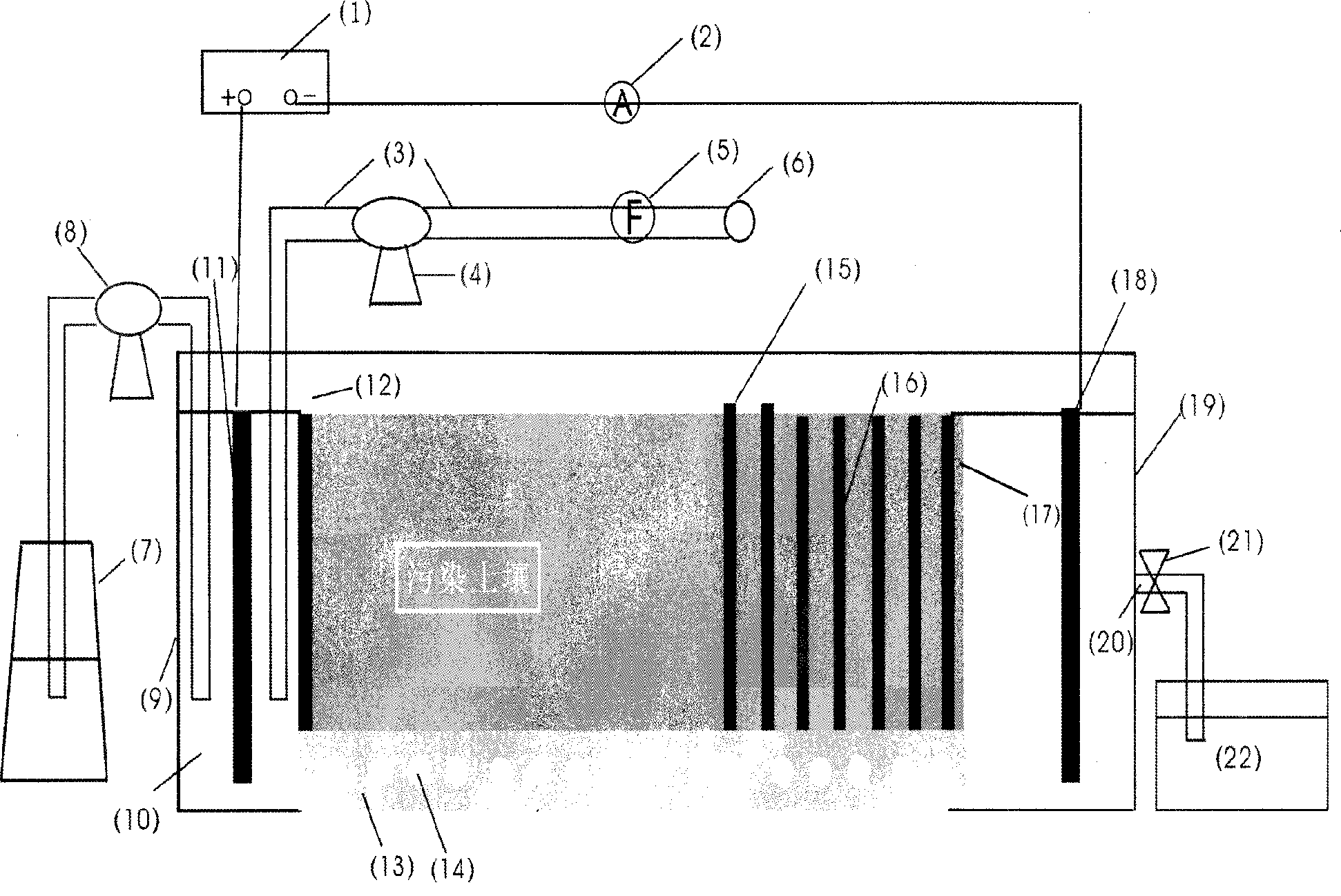

[0022] Using polluted soil anolyte leaching to strengthen electrokinetic remediation process methods such as figure 1 The device is repaired, and the whole repair device is 10 cm wide and 16 cm high. The lengths of the anode electrolysis chamber 9, the processing soil, and the cathode electrolysis chamber 19 are 5 cm, 50 cm, and 8 cm, respectively. Add 0.3mol / l tartaric acid solution in the anode electrolysis chamber 9, and 0.05mol / l KNO in the cathode electrolysis chamber 19 3 solution. From the cathode electrolysis chamber 19, 6 coarse gravels with a particle size of 1.2 mm at intervals of 3 cm are used to wash and infiltrate the thin layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com