Multi-stage pulse sequence control method of pseudo-continuous working mode and apparatus thereof

A pseudo-continuous operation and mode switching technology, which is applied in the field of multi-level pulse sequence control of pseudo-continuous operation mode switching power supply and its devices, can solve the problems of large fluctuation of the output voltage of the converter and is not suitable for high-power occasions, and achieves widening Application-wide effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

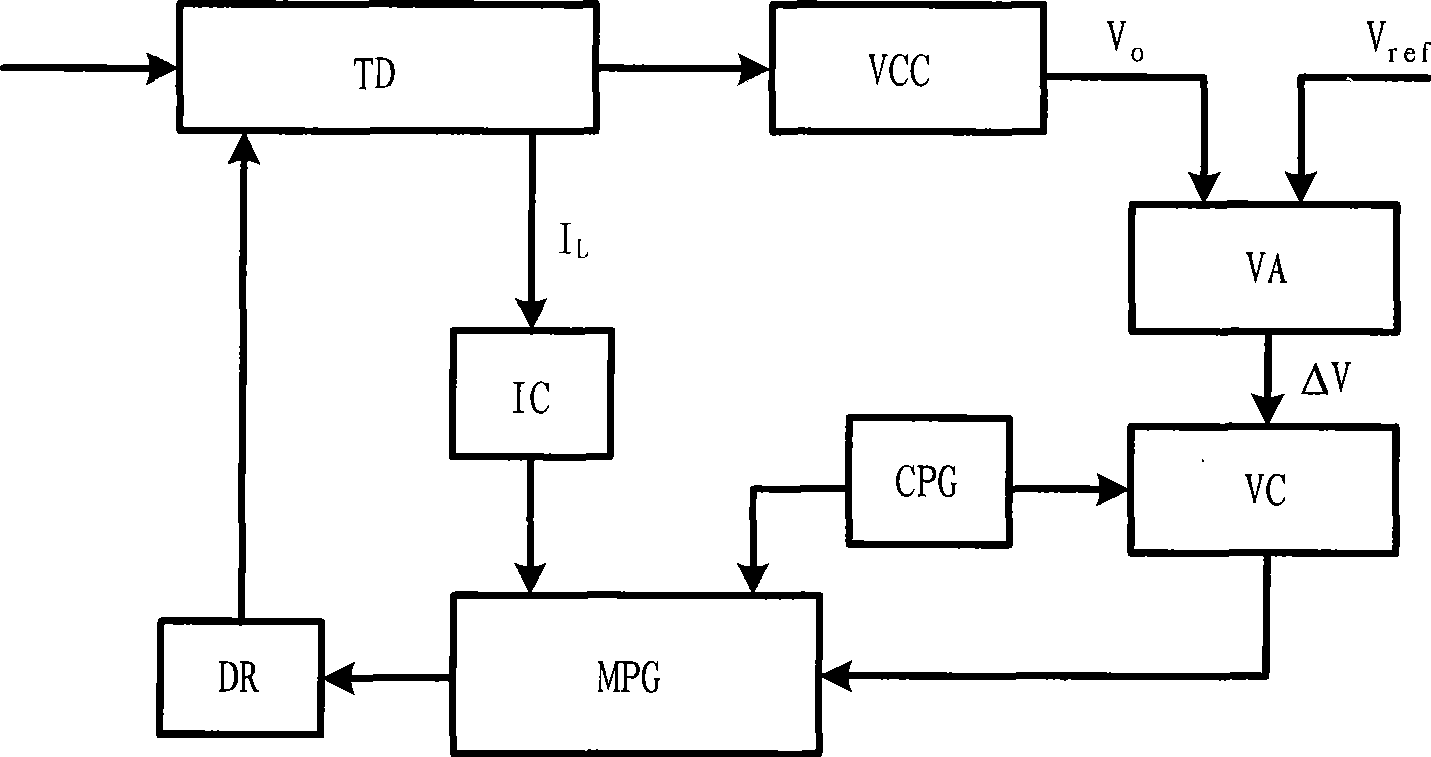

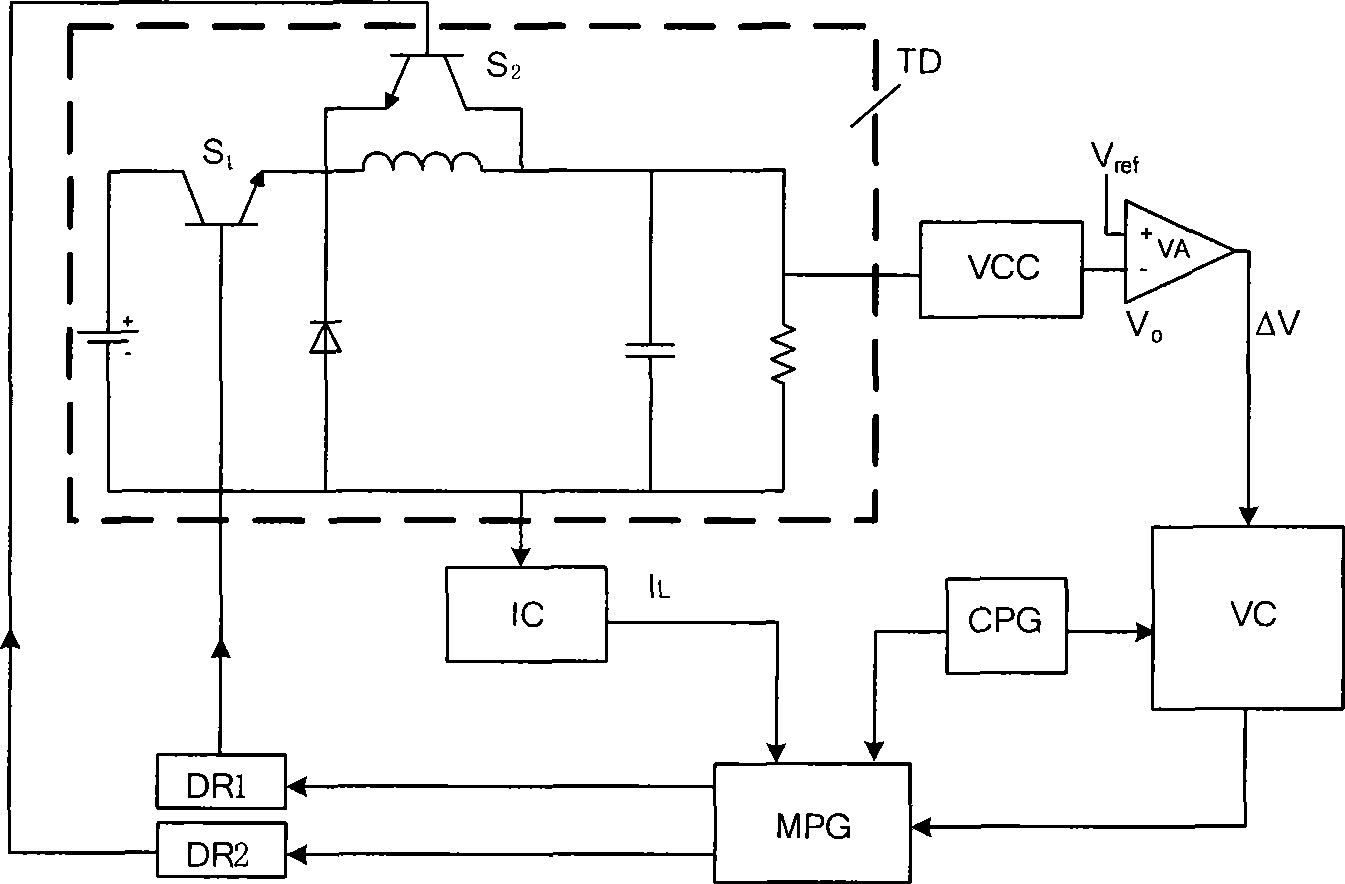

[0045] figure 1 It is shown that a specific embodiment of the present invention is a control method of a switching power supply, and its specific method is:

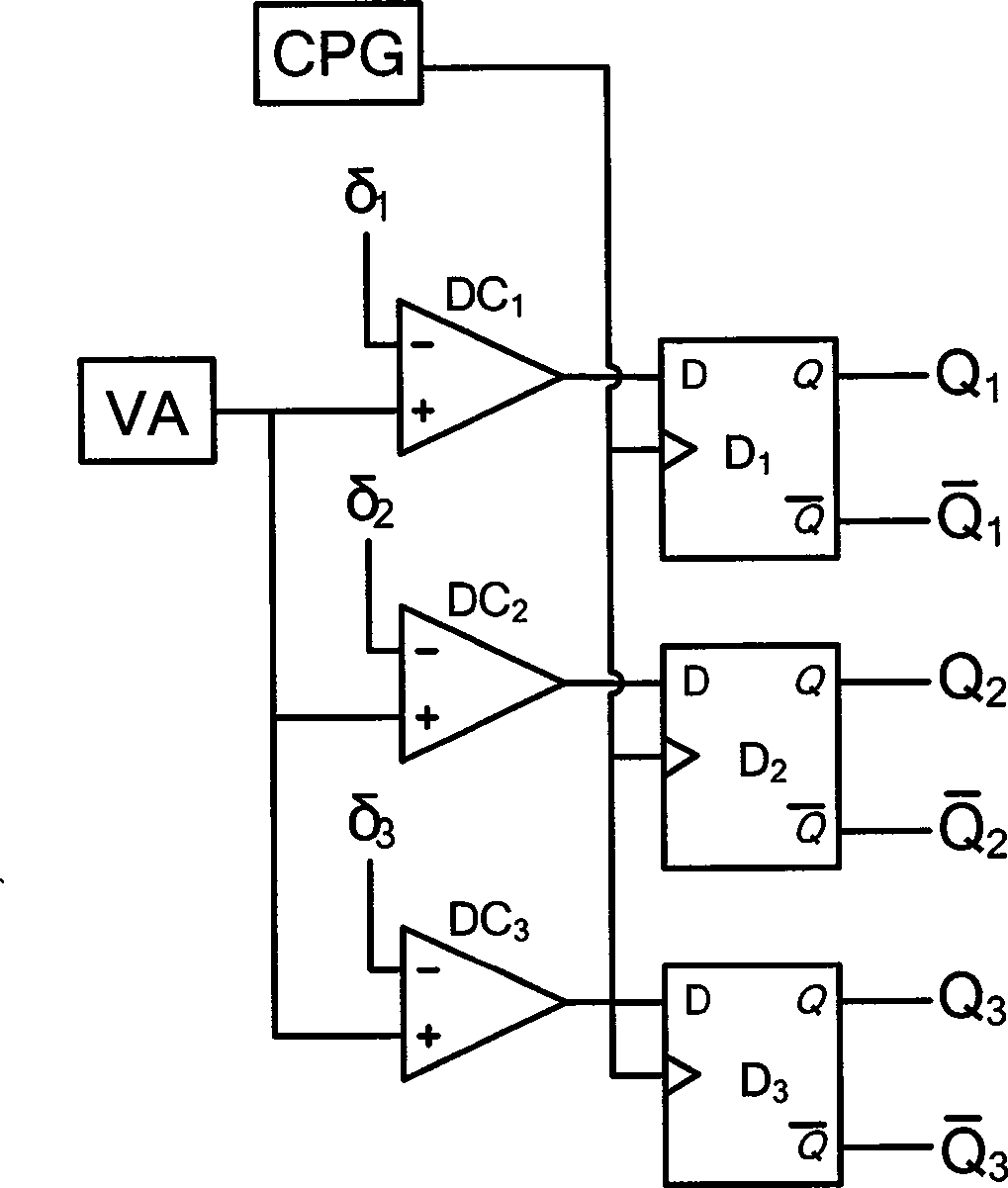

[0046] The voltage detection circuit VCC detects the output voltage V of the converter TD 0 , the error amplifier VA uses the output reference voltage V at the beginning of each switching cycle ref with the output voltage V 0 The error voltage value ΔV is generated by comparison; the error interval judger VC compares the error voltage value ΔV with the set N=3 output voltage error interval value δ n , n=1, 2, 3, compare, and output corresponding control pulse selection signals to the multi-level pulse generator MPG according to the comparison results, the comparison and selection rules are: when ΔV>δ 1 When , the output signal of the error interval judge VC makes the multi-level pulse generator MPG generate a control pulse P 11 and P 12 ; when δ 1 ≥ΔV>δ 2 When , the output signal makes the multi-stage pulse genera...

Embodiment 2

[0063] Figure 8 It shows that this example is basically the same as Embodiment 1, the difference is that: the number N of error interval values of the set output voltage is 4, and δ n , n=1, 2, 3, 4, the corresponding control pulse P n1 is five, namely P 11 ,P 21 ,P 31 ,P 41 ,P 51 . Multi-stage pulse generator MPG generates control pulse P n , the method of n=1, 2, 3, 4, 5 is: the multistage pulse generator (MPG) outputs P at the beginning of each switching cycle n1 is high level, P n2 is low, the inductor current I in the converter (TD) L start to rise;P n1 Continuous high level fixed time D n After T, it becomes low level; the current I L then begins to drop, when I L drops until the current valley I V , the control pulse P n2 From low level to high level, the diode is turned off, and the inductor current passes through the switch tube S 2 freewheel until the end of the switching cycle.

[0064] The converter TD of the switching power supply controlled in...

Embodiment 3

[0066] Figure 9 It shows that this example is basically the same as the first example, the difference is: the number N of error interval values of the set output voltage is 5, and δ n , n=1, 2, 3, 4, 5, the corresponding control pulse P n1 is six, namely P 11 ,P 21 ,P 31 ,P 41 ,P 51 ,P 61 . Multi-stage pulse generator MPG generates control pulse P n , the method of n=1, 2, 3, 4, 5, 6 is: the multistage pulse generator (MPG) outputs P at the beginning of each switching cycle n1 is high level, P n2 is low, the voltage V on the equivalent series resistance (ESR) of the capacitor in the converter (TD) ESR Start to rise; the voltage detection circuit (VCC') detects the voltage V synchronously ESR , the multistage pulse generator (MPG) takes the voltage signal V ESR with the period of the control pulse P n1 , n=1, 2,...N+1, the corresponding peak voltage V n , n=1, 2,...N+1, for comparison, when the voltage V ESR rises to the peak value corresponding to V n , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com