Novel biological contamination-resistant ultrathin compound film and preparation method thereof

A bio-resistant and composite membrane technology, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems such as the difficulty of obtaining p-benzenetriamine, achieve good antibacterial effect, high desalination performance, and convenient preparation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

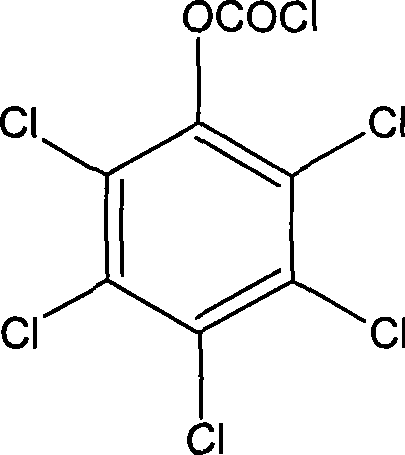

Image

Examples

Embodiment 1

[0025] Use 16% Udel P3500 polysulfone, 0.3% water and 0.1% nonylphenol polyoxyethyl ester phosphate dissolved in N,N-dimethylformamide, scrape on the polyester non-woven fabric, and then dip into After the solvent is removed from the water, a support membrane with a molecular weight cut-off of 20,000-30,000 is obtained, which is stored in a wet state for future use.

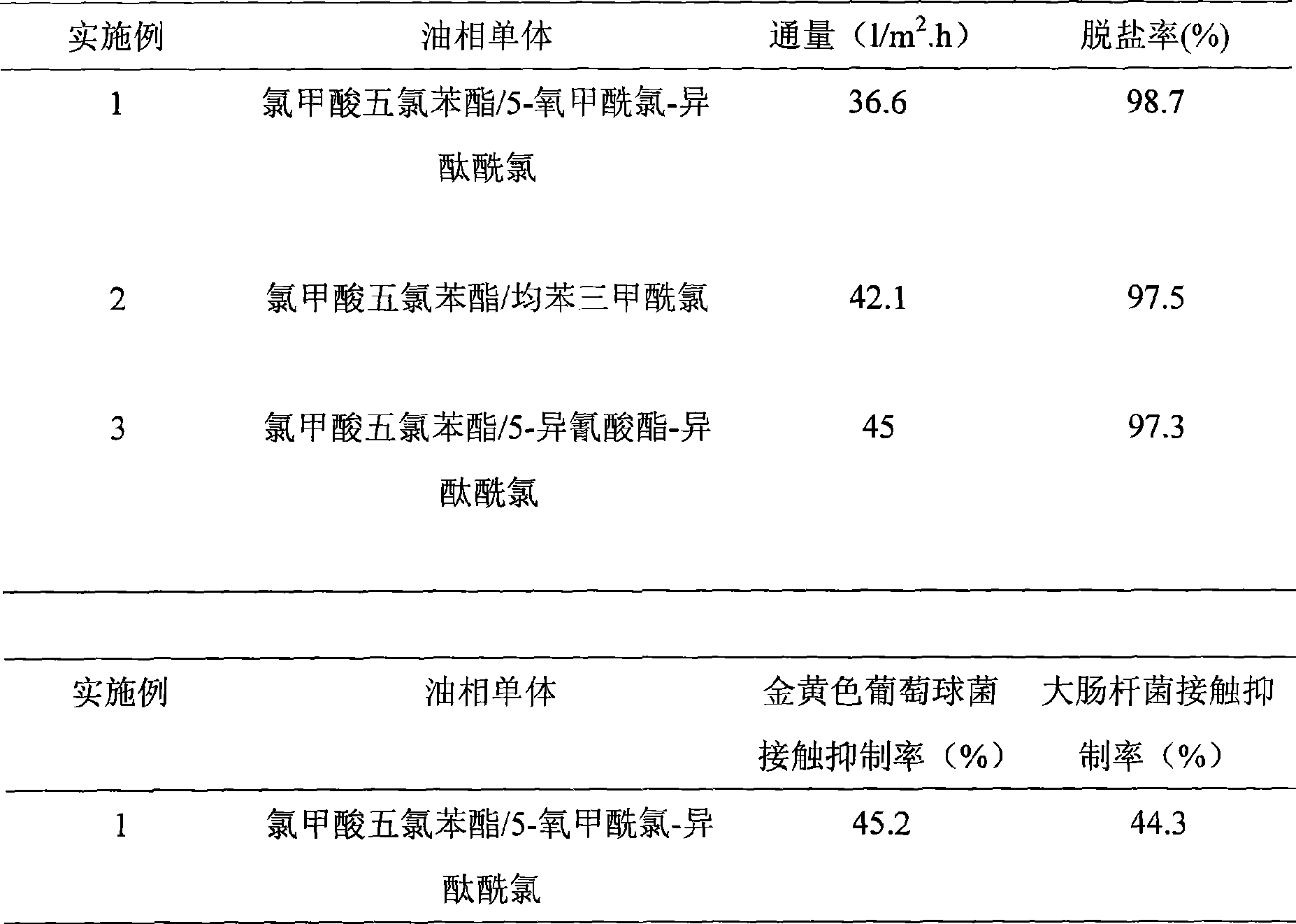

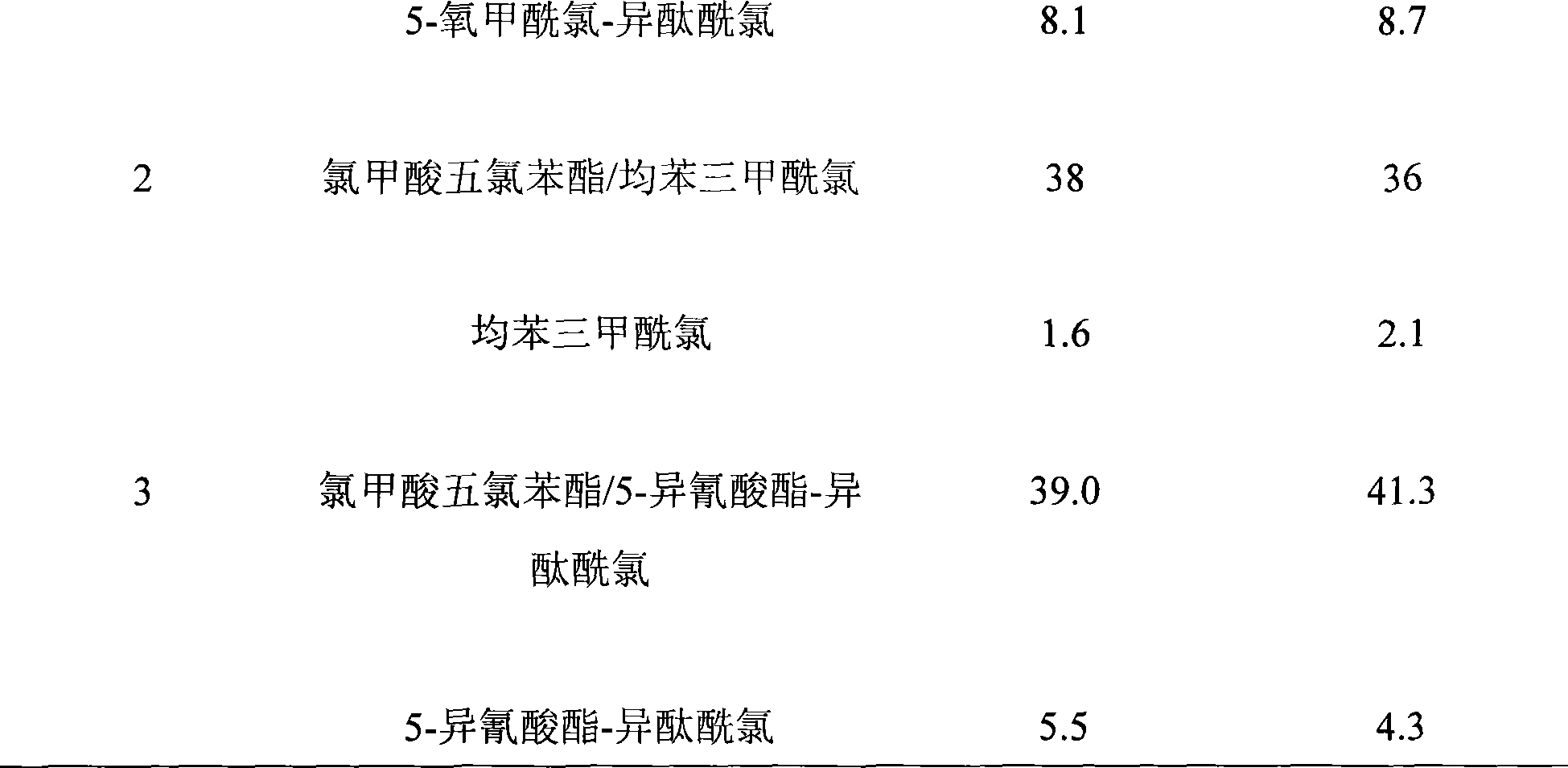

[0026] Immerse one side of the wet polysulfone support membrane in an aqueous solution with a weight ratio of m-phenylenediamine of 2% for 2 minutes, roll the surface of the support membrane with a rubber roller and squeeze it dry, and mix it with pentachlorophenyl chloroformate and 5-oxygen Formyl chloride-isophthaloyl chloride mixed in a weight ratio of 1:5, and a 0.12% by weight cyclohexane solution was contacted on one side to carry out interfacial polymerization for 30 seconds. The composite film was dried in the air for 2 minutes, and then treated at 40°C for 3 minutes. Then carry out two steps of rinsing ...

Embodiment 2

[0028] Use 16% Udel P3500 polysulfone, 0.3% water and 0.1% nonylphenol polyoxyethyl ester phosphate dissolved in N,N-dimethylformamide, scrape on the polyester non-woven fabric, and then dip into After the solvent is removed from the water, a support membrane with a molecular weight cut-off of 20,000-30,000 is obtained, which is stored in a wet state for future use.

[0029] Immerse one side of the wet polysulfone support membrane in an aqueous solution with a weight ratio of m-phenylenediamine of 2% for 4 minutes, roll the surface of the support membrane with a rubber roller and squeeze it dry, and mix it with pentachlorophenyl chloroformate and trimesin The weight ratio of acid chloride mixing is 1:5, and the cyclohexane solution with 0.12% by weight is contacted on one side to carry out interfacial polymerization reaction for 20 seconds. The composite film was dried in the air for 2 minutes, and then treated at 50°C for 5 minutes. Then carry out two steps of rinsing again:...

Embodiment 3

[0031] Use 16% Udel P3500 polysulfone, 0.3% water and 0.1% nonylphenol polyoxyethyl ester phosphate dissolved in N,N-dimethylformamide, scrape on the polyester non-woven fabric, and then dip into After the solvent is removed from the water, a support membrane with a molecular weight cut-off of 20,000-30,000 is obtained, which is stored in a wet state for future use.

[0032]Immerse one side of the wet polysulfone support membrane in an aqueous solution with a weight ratio of m-phenylenediamine of 2% for 5 minutes, roll the surface of the support membrane with a rubber roller and squeeze it dry, and mix it with pentachlorophenyl chloroformate / 5-oxygen The mixing ratio of formyl chloride-isophthaloyl chloride or trimesoyl chloride or 5-isocyanate-isophthaloyl chloride is 1:5, and the cyclohexane solution with 0.12% by weight is contacted on one side for interfacial polymerization reaction for 40 seconds. The composite film was dried in the air for 2 minutes, and then treated at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com