High-efficient trapping system for micro-nano powder dust in air

A medium, micro, nano, and air technology, which is applied in the field of wet high-efficiency capture systems, can solve problems such as difficulties in nano-scale particles, low capture efficiency of nano-dust, affecting capture efficiency and test accuracy, and achieve high-efficiency capture , The effect of high-efficiency capture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

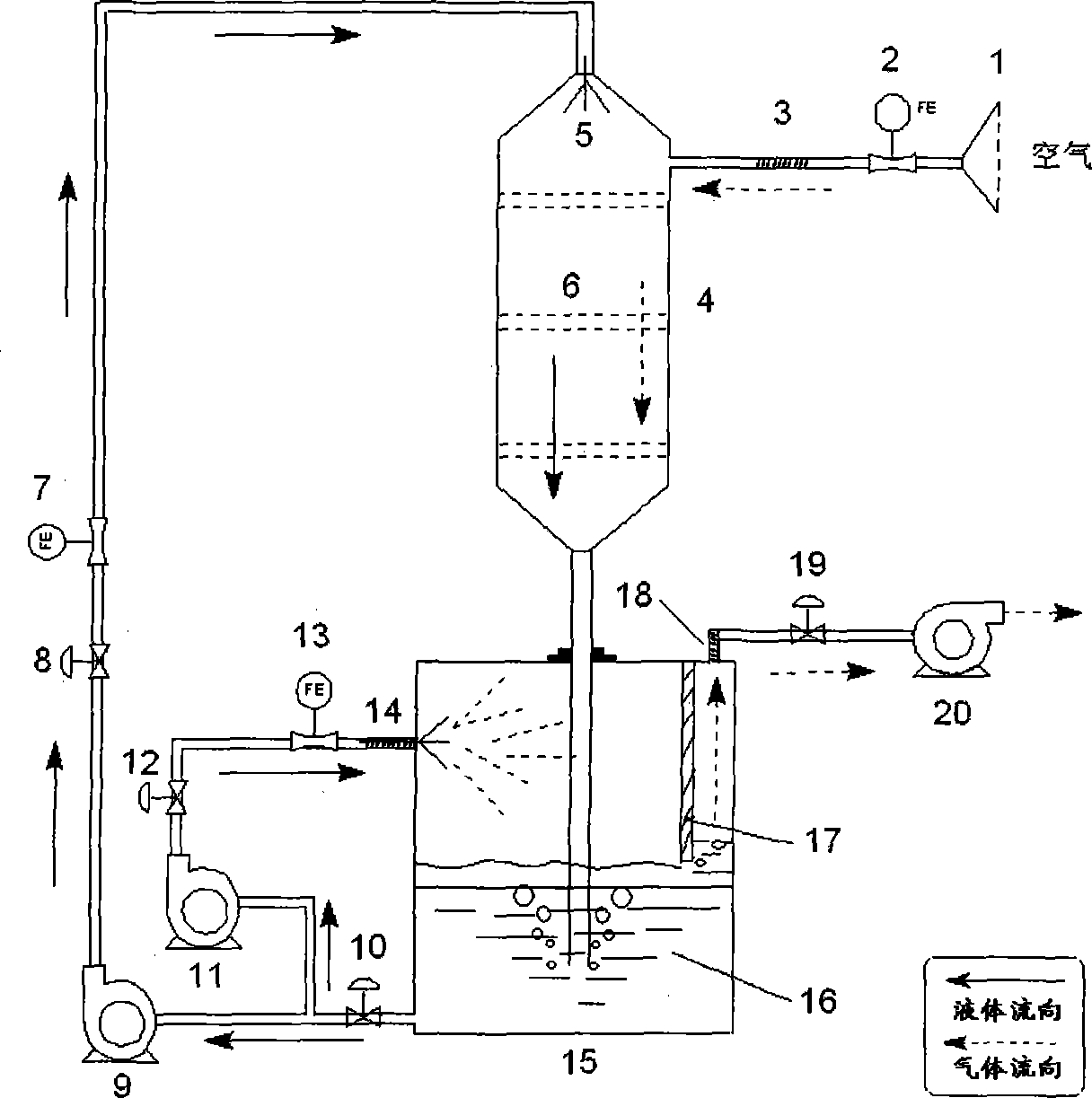

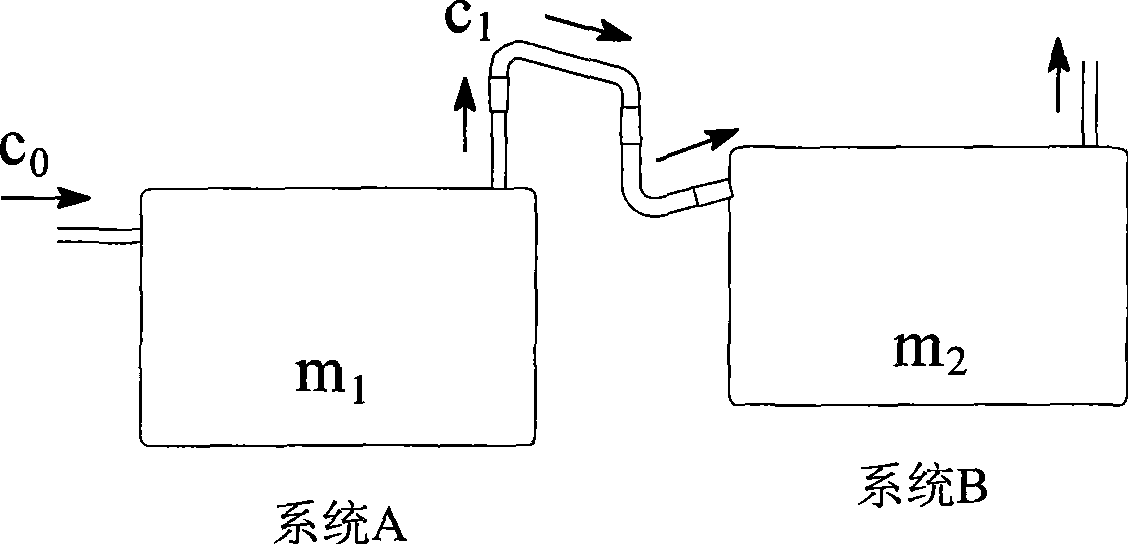

[0029] Under normal temperature and pressure, the components of the system are figure 1 The structure is assembled and connected. Accurately inject 8.0L of deionized water into the liquid storage chamber 15 as the trapping liquid, and then test the airtightness of the system. After closing the gas flow meter 2, fully open the large flow liquid flow meter 7, the large flow liquid valve 8, the liquid main valve 10, the small flow liquid valve 12, the small flow liquid flow meter 13 and the gas valve 19, turn on the vacuum pump 20 and run After 10 minutes, no air bubbles are generated in the liquid storage chamber 15, which means the airtightness is qualified.

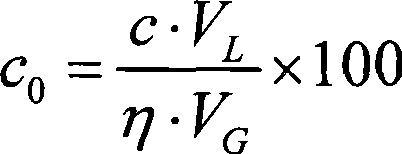

[0030] Place the system that has been assembled and passed the air tightness test in the hydrophilic nano-titanium dioxide powder production workshop, fix the trapping port 1, and make it face the direction of the main dust generation point or face the dust-laden airflow (if there is an obvious air flow). First open th...

Embodiment 2

[0039] According to the method of Example 1, the trapping solution 16 was replaced with low-volatility cyclohexanone to trap the nano-dust in the air of the lipophilic nano-titanium dioxide powder production workshop. The calculation method of the dust concentration in the air is the same as in Example 1.

Embodiment 3

[0041] According to the method of Example 1, the nano-dust in the air of the hydrophilic nano-silica powder (fumed silica) production workshop was collected. The calculation method of the dust concentration in the air is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com