Glipizide enteric-coated formulation composition and method for preparing the same

A technology of glipizide enteric and glipizide, which is applied in the field of medicine, can solve problems such as no reports of glipizide enteric-coated capsules and enteric-coated granules, and achieve controllability and good stability of the preparation process quality , to avoid the nauseating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Enteric-coated capsules

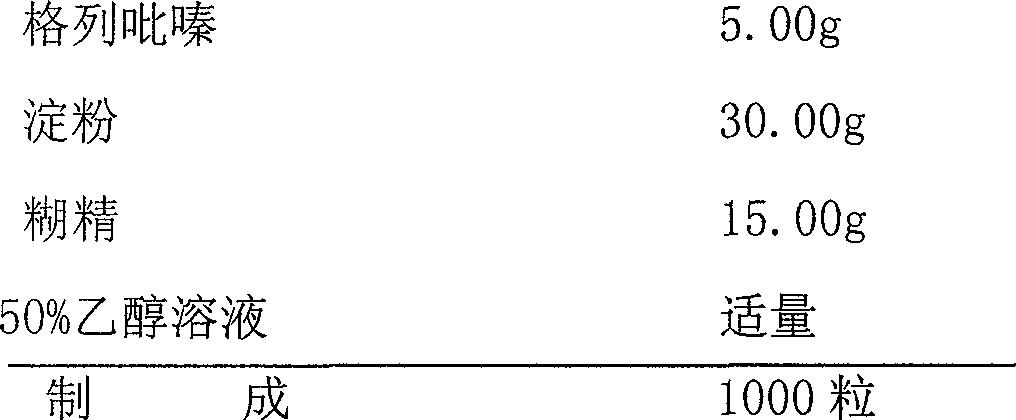

[0025] prescription:

[0026]

[0027] Preparation Process:

[0028] Pass glipizide, starch and dextrin through 80-mesh sieve respectively, weigh starch and dextrin according to the prescription amount, put them in a mixer and mix them with glipizide in equal increments, add 50% ethanol solution Appropriate amount of soft material is prepared, granulated in a granulator, and the granules are dried at 45°C for 30 minutes, then passed through a swing granulator, and sized with a 20-mesh sieve. The content of the mixed granules is determined, and the filling capacity of the enteric-coated capsule shell is determined. After passing the inspection, pack.

[0029] The glipizide enteric-coated capsules prepared by the above-mentioned method meet the requirements of the relevant testing items stipulated in the "General Rules of Preparations" of the "Chinese Pharmacopoeia 2005 Edition Part II".

Embodiment 2

[0031] Enteric-coated pellets and capsules

[0032] Prescription: Su Micropills

[0033] Glipizide 1.00g

[0034] Xylose 15.00g

[0035] Microcrystalline Cellulose 25.00g

[0036] Magnesium stearate 0.50g

[0037] 50% ethanol solution appropriate amount

[0038] Makes 1000 capsules

[0039] Prescription: enteric coating solution

[0040] 4 parts talcum powder

[0041] Titanium dioxide 6 parts

[0042] Polyacrylic resin II 20 parts

[0043] Polyacrylic resin III 10 parts

[0044] Tween 80 1.5 parts

[0045] 3 parts propylene glycol

[0046] 50% ethanol solution appropriate amount

[0047] Preparation Process:

[0048] Pass the glipizide, xylose, microcrystalline cellulose, and magnesium stearate through a 120-mesh sieve respectively, weigh the xylose, microcrystalline cellulose, and magnesium stearate according to the prescription amount of the plain pellets, put them in a mixer and mix them Then mix it with glipizide in equal increments, place it in a centrifugal...

Embodiment 3

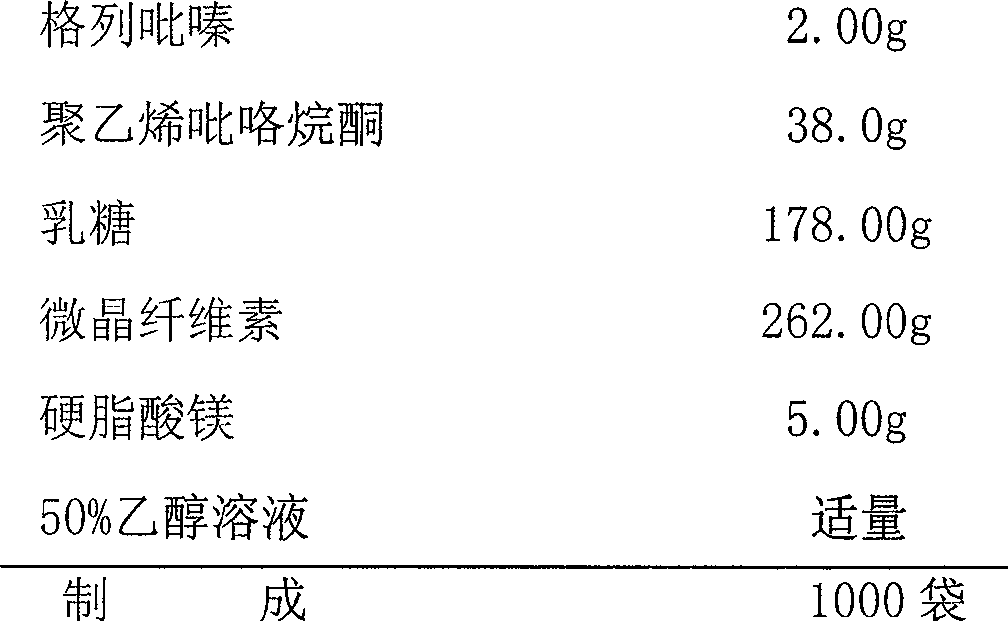

[0051] Enteric-coated granules

[0052] Prescription: vegetarian granules

[0053]

[0054] Prescription: enteric coating solution

[0055] 4 parts talcum powder

[0056] Titanium dioxide 6 parts

[0057] Hypromellose Phthalate 35 parts

[0058] Tween 80 1 serving

[0059] 3 parts propylene glycol

[0060] 50% ethanol solution appropriate amount

[0061] Preparation Process:

[0062] Glipizide, polyvinylpyrrolidone, lactose, microcrystalline cellulose, and magnesium stearate were passed through a 120-mesh sieve respectively, and polyvinylpyrrolidone, lactose, microcrystalline cellulose, and magnesium stearate were weighed according to the prescription amount of plain granules. After mixing in a mixer, mix with glipizide in equal increments, place in a centrifugal granulator, spray an appropriate amount of 50% ethanol solution to prepare the granules, and prepare the coating solution for the granules according to the prescription of the enteric coating solution. The gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com