LCD

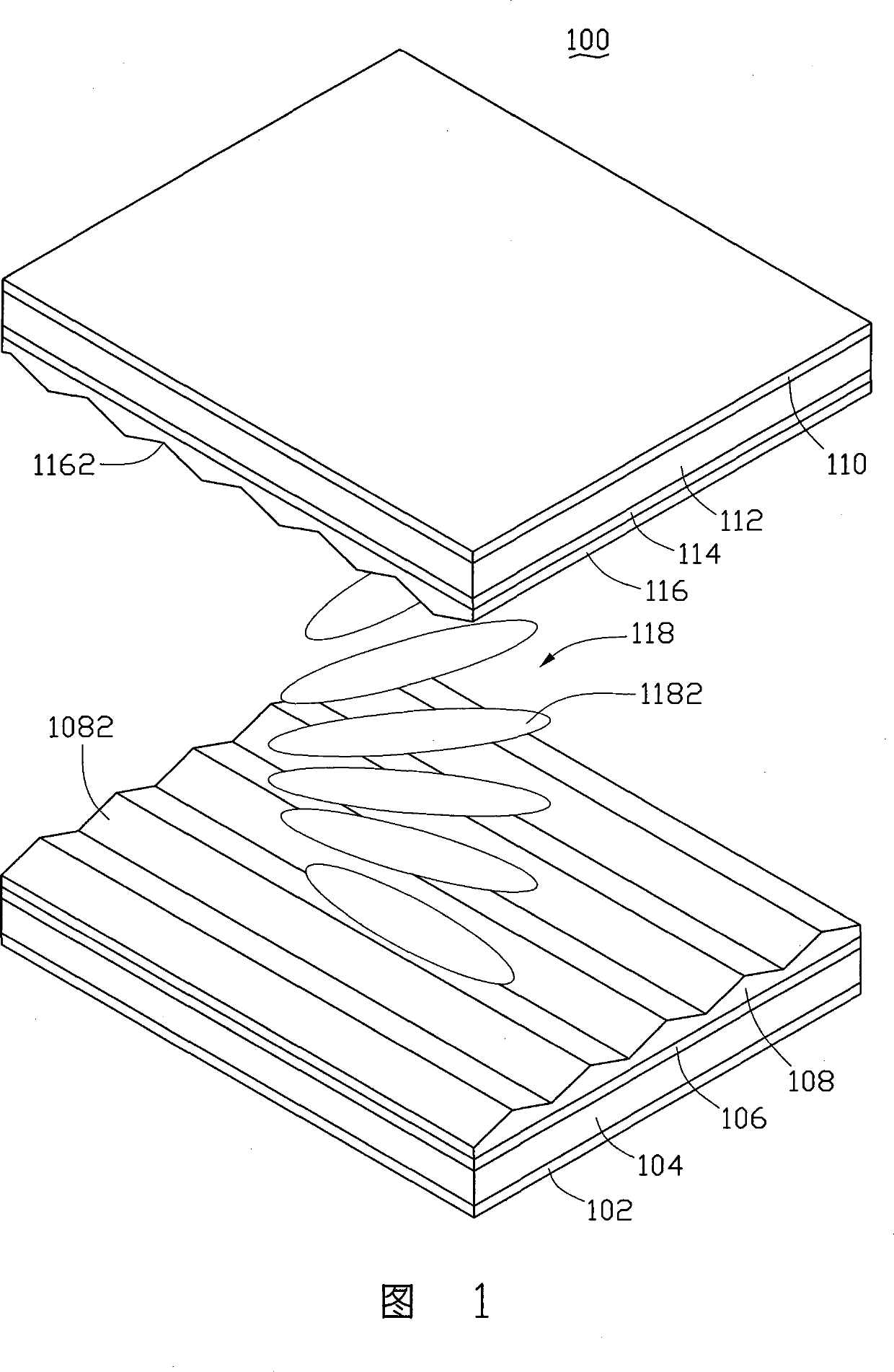

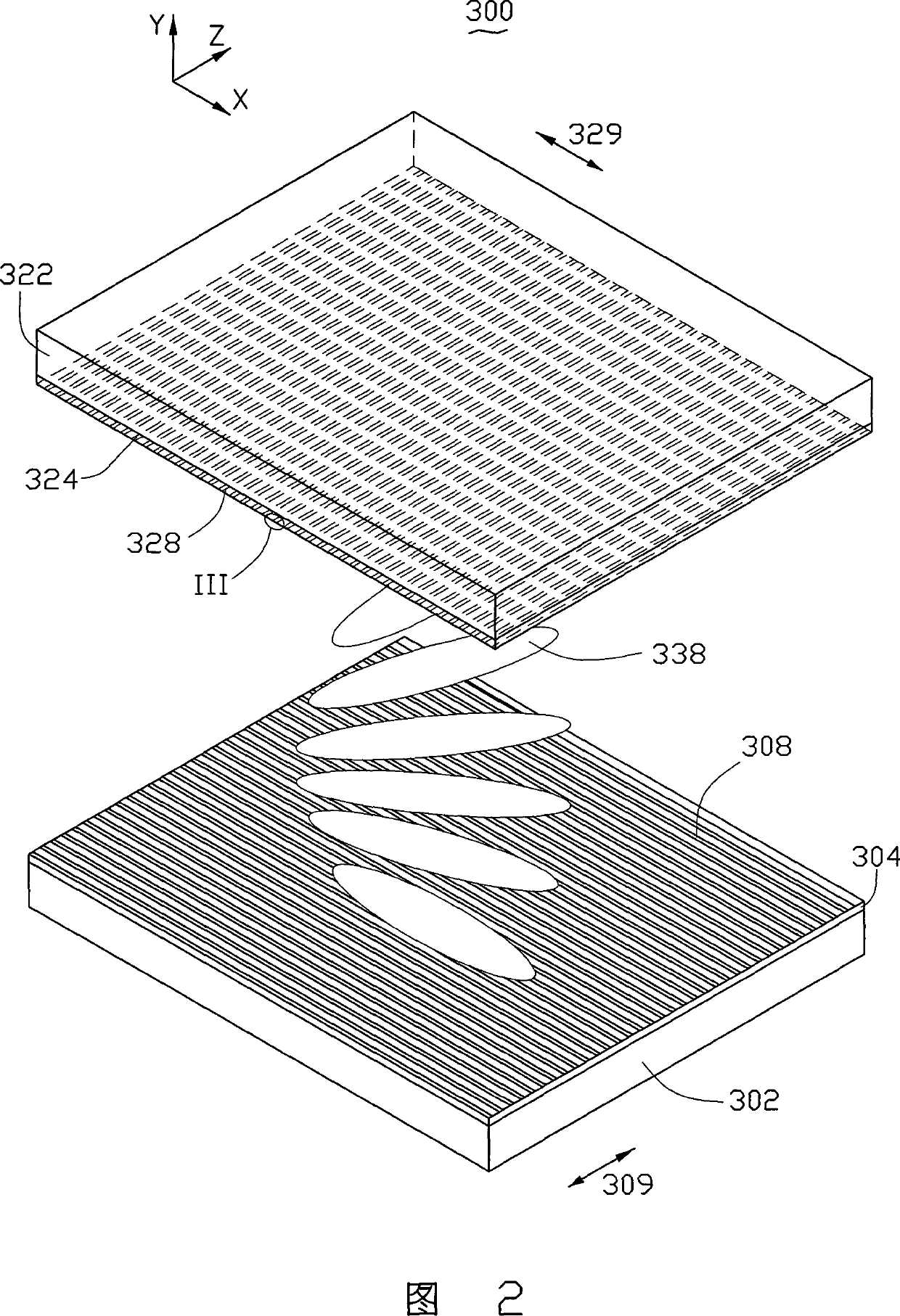

A liquid crystal display and liquid crystal layer technology, applied in optics, instruments, nonlinear optics, etc., can solve the problem of reducing the light transmittance of the backlight source, affecting the display quality, increasing the thickness of the liquid crystal display 100, complexity and manufacturing costs, etc. Problems, to achieve the best alignment quality, improve utilization, and improve the effect of display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

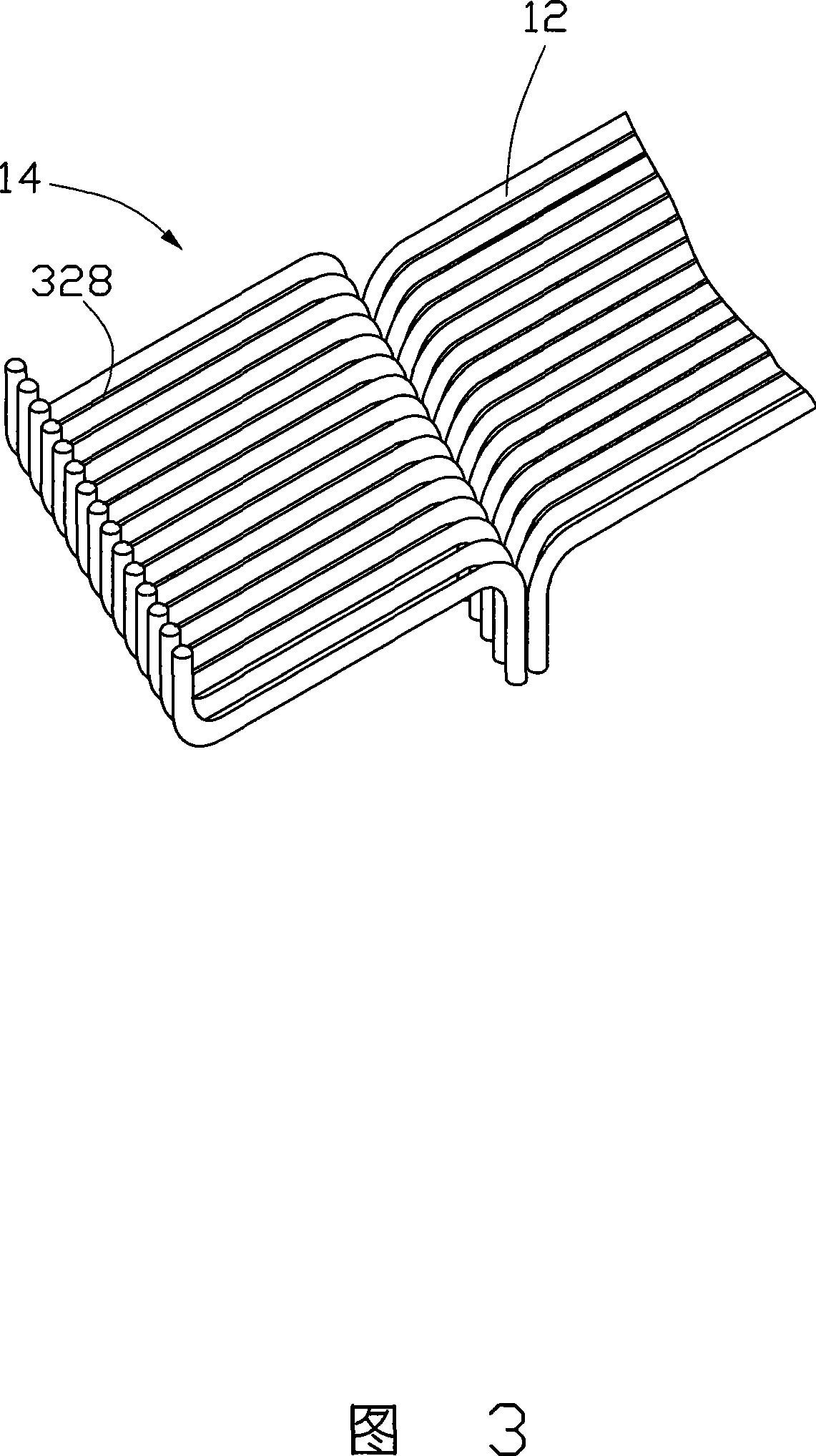

[0025] The preparation method of described carbon nanotube layer comprises the following steps:

[0026] Step 1: providing a carbon nanotube array, preferably, the array is a super-aligned carbon nanotube array.

[0027] The carbon nanotube array provided in the embodiment of the technical solution is a single-wall carbon nanotube array, a double-wall carbon nanotube array or a multi-wall carbon nanotube array. In this embodiment, the preparation method of the super-parallel carbon nanotube array adopts the chemical vapor deposition method, and the super-parallel carbon nanotube array is a pure carbon nanotube array formed by a plurality of carbon nanotubes parallel to each other and perpendicular to the substrate. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com