Biomass high temperature pyrolysis and gasification power generation system

A technology of pyrolysis gasification and biomass gas, which is applied in the direction of gas dust removal, chemical industry, and the manufacture of combustible gas. It can solve problems such as plugging spark plugs or gas holes, power generation and gas supply cannot operate normally, and pollutes cylinders to achieve thermal efficiency. High, easy to operate, control and maintain, low heat generation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

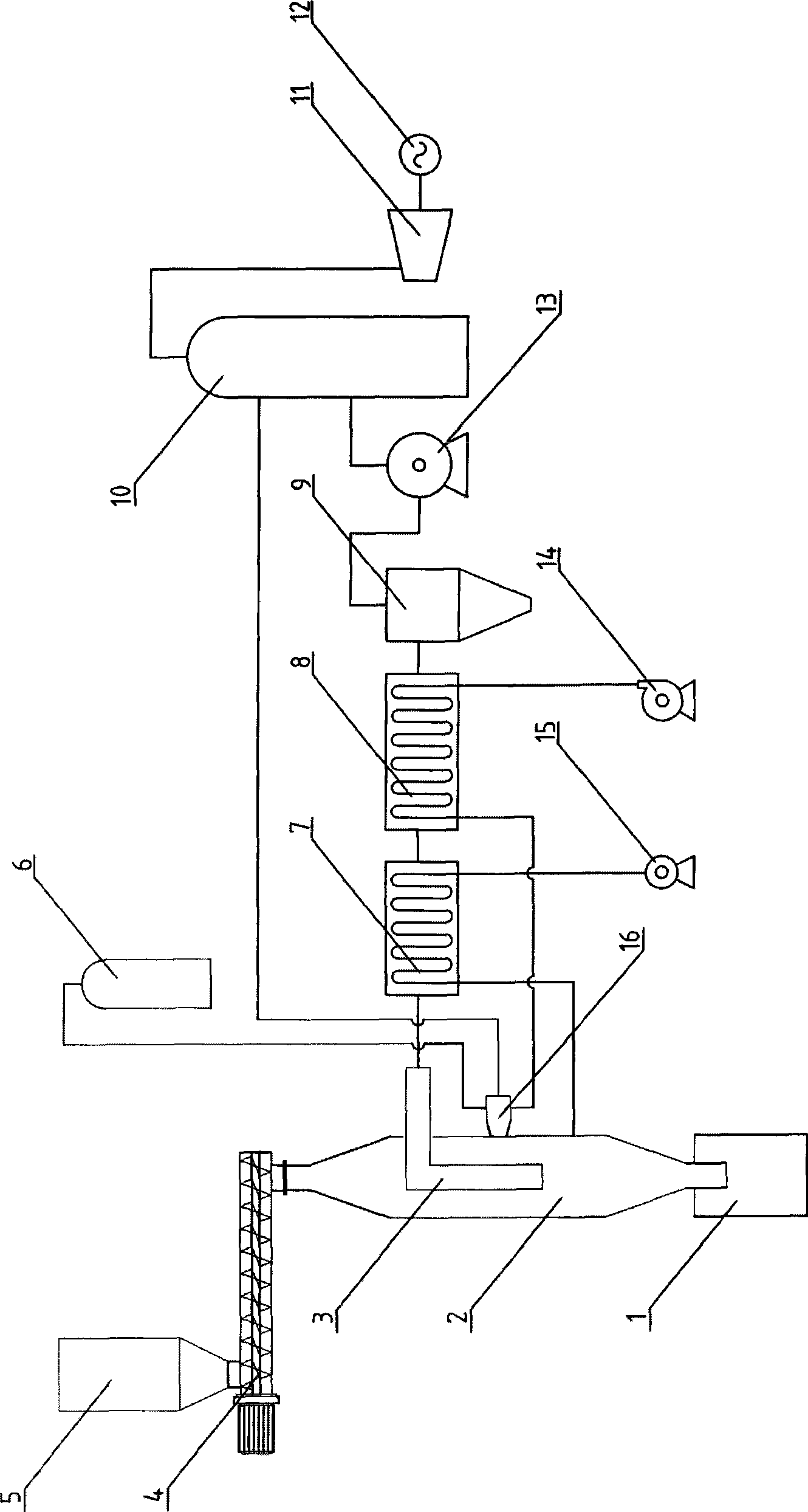

[0025] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A biomass high-temperature pyrolysis gasification power generation system includes a biomass cyclone pyrolysis gasification furnace chamber 2, a biomass material bin 5 arranged on the upper part, an ash pool 1 arranged on the lower part, and a biomass gas discharge chamber arranged inside it. Pipe 3, and biomass gas waste heat utilization steam generator 7, biomass gas waste heat utilization air heater 8, biomass gas dust collector 9, water ring vacuum pump 13, biomass gas storage gas set according to the main process of biomass gas Tank 10 and internal combustion engine 11 connected to generator 12 . In addition, the high-velocity gas fuel burner 16 respectively connected to the fuel gas tank 6 and the biomass gas storage tank 10 at the start-up stage is arranged outside the biomass cyclone pyrolysis gasifier chamber 2 and communicates with it.

[0026...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com