Method for plating tantalum on TiNi alloy surface

A technology of alloy and coating machine, which is applied in the field of tantalum plating on the surface of alloys, and can solve problems such as poor corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

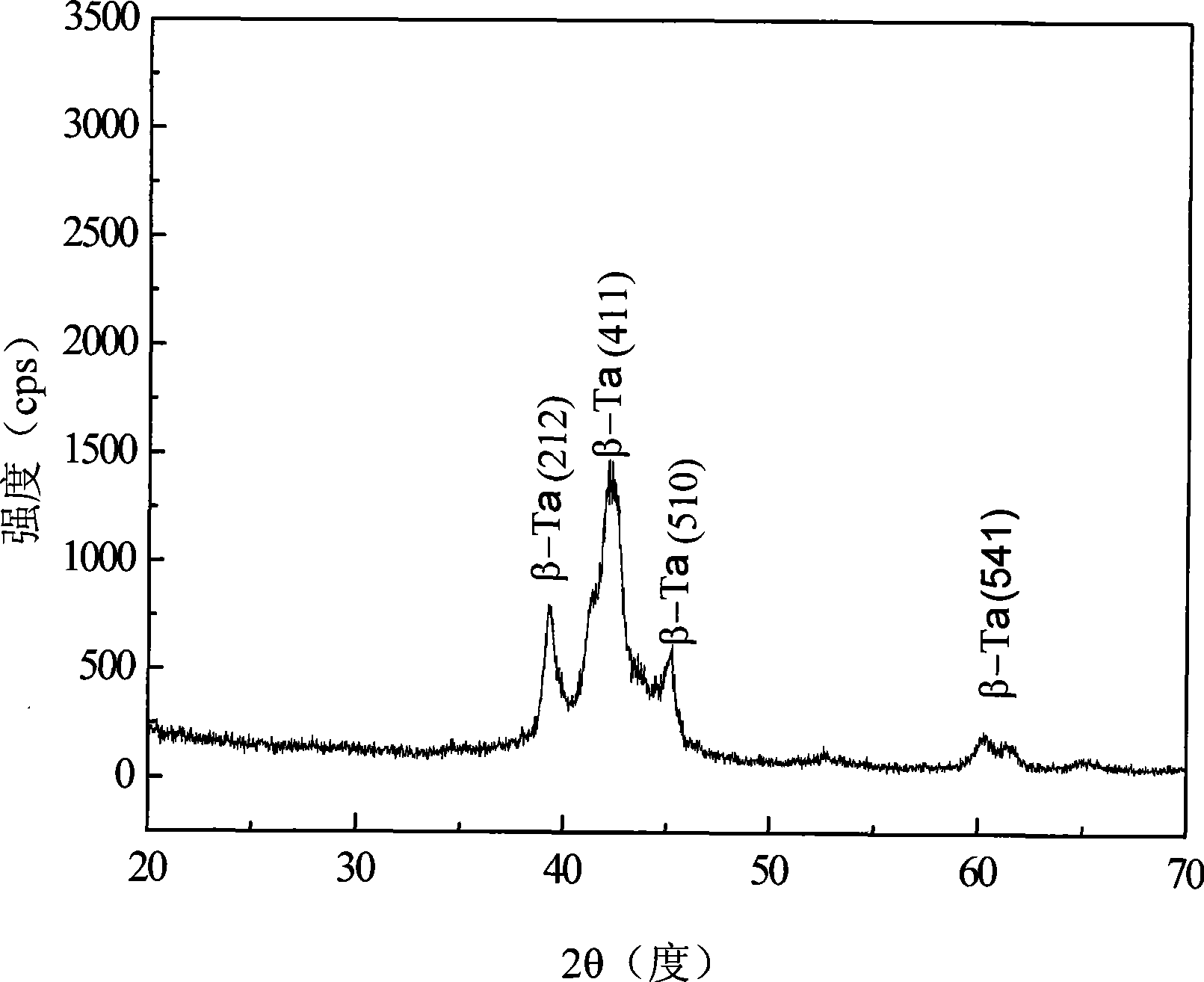

[0008] Specific Embodiment 1: The method for plating tantalum on the surface of TiNi alloy in this embodiment is realized according to the following steps: 1. Mechanically polish the TiNi alloy, then put it into acetone for ultrasonic cleaning for 20-60 minutes, and then dry it; 2. TiNi after drying The alloy is put into the multi-arc ion coating machine, and the vacuum is evacuated until the pressure of the multi-arc ion coating machine is 10 -4 ~10 -5 Pa, and then introduce argon gas until the pressure in the furnace is 0.2-0.3Pa, apply a negative bias voltage of 800-1100V to the TiNi alloy, and perform sputtering cleaning until the TiNi alloy reaches 300-400°C; Under the conditions of 70-80A and negative bias of 100-500V, bombard the TiNi alloy treated in step 2 with tantalum ions and deposit it. The deposition time is 30-160min, and then cool to room temperature; 4. Vacuum at 800-1000°C Anneal for 30 to 90 minutes to obtain a tantalum-plated TiNi alloy.

specific Embodiment approach 2

[0009] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 1, ultrasonic cleaning is performed for 30-50 minutes. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Embodiment 3: The difference between this embodiment and Embodiment 1 is that in step 1, ultrasonic cleaning is performed for 40 minutes. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com