Methane chlorides production process utilizing chlorination reaction heat

A methane chloride, production process technology, applied in chemical recovery, organic chemistry, chemical instruments and methods, etc., can solve problems such as energy waste, achieve the effects of reducing production costs, saving energy, and reducing steam consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

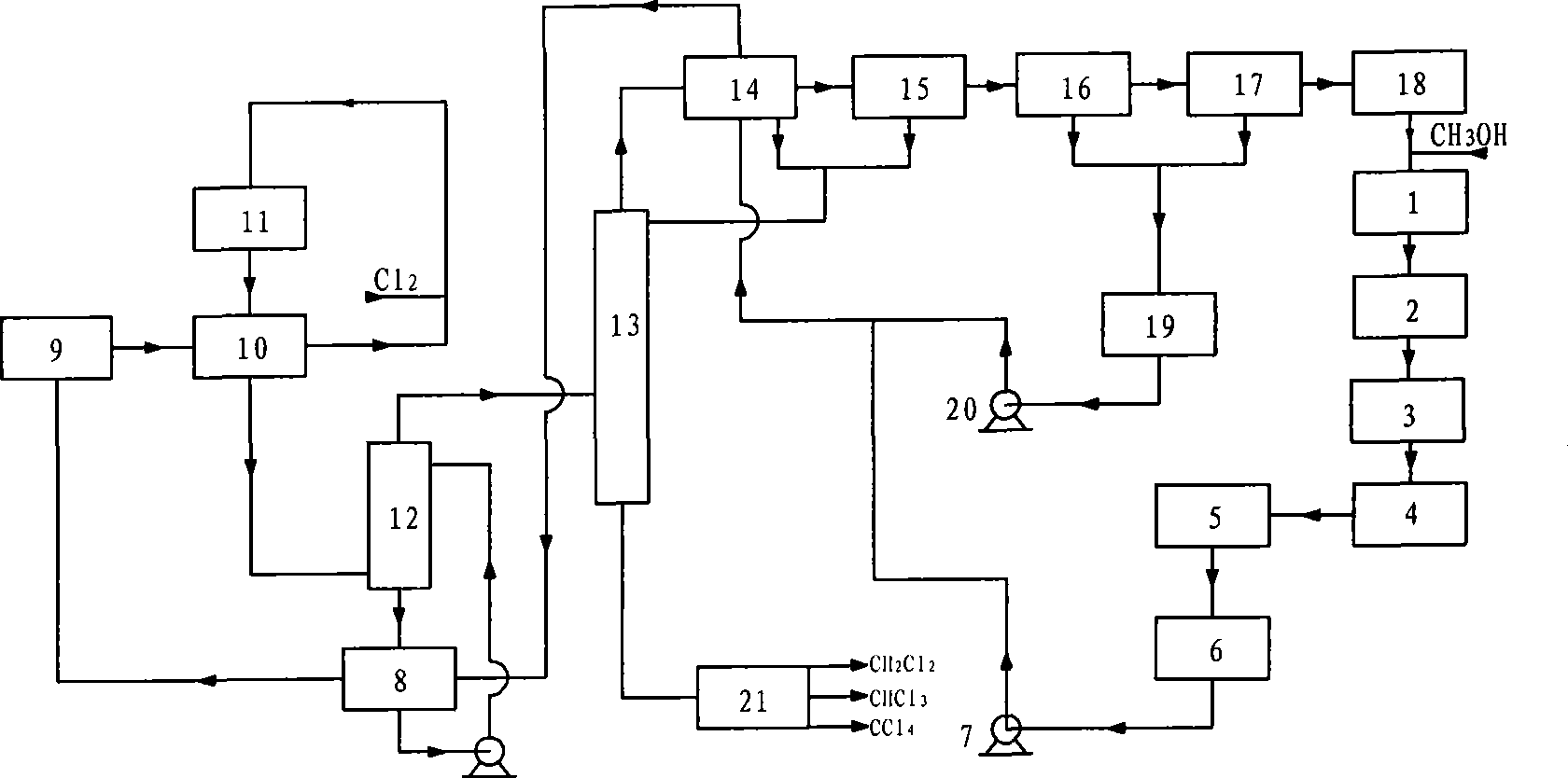

[0021] Such as figure 1 As shown, the methane chloride production process utilizing the heat of chlorination reaction in this embodiment includes a hydrochlorination process and a chlorination process:

[0022] Hydrochlorination process: Mix methanol gas and hydrogen chloride gas and pass them into hydrochlorination reactor 1 for reaction. The reaction mixture is cooled by cooling device 2, absorbing device 3 removes unreacted hydrogen chloride, and sulfuric acid drying device 4 removes the generated water. The monochloromethane gas is obtained, and then under the self-pressure of the hydrochlorination reaction system of 0.4-0.8Mpa, it is condensed through the condenser 5 with a refrigerant temperature of -20-10°C to obtain the monochloromethane liquid, which enters the monochloromethane storage tank 6 for standby ;

[0023] Chlorination process: the monochloromethane liquid obtained in the hydrochlorination process and the low-chloride liquid separated from the chlorination ...

Embodiment 2

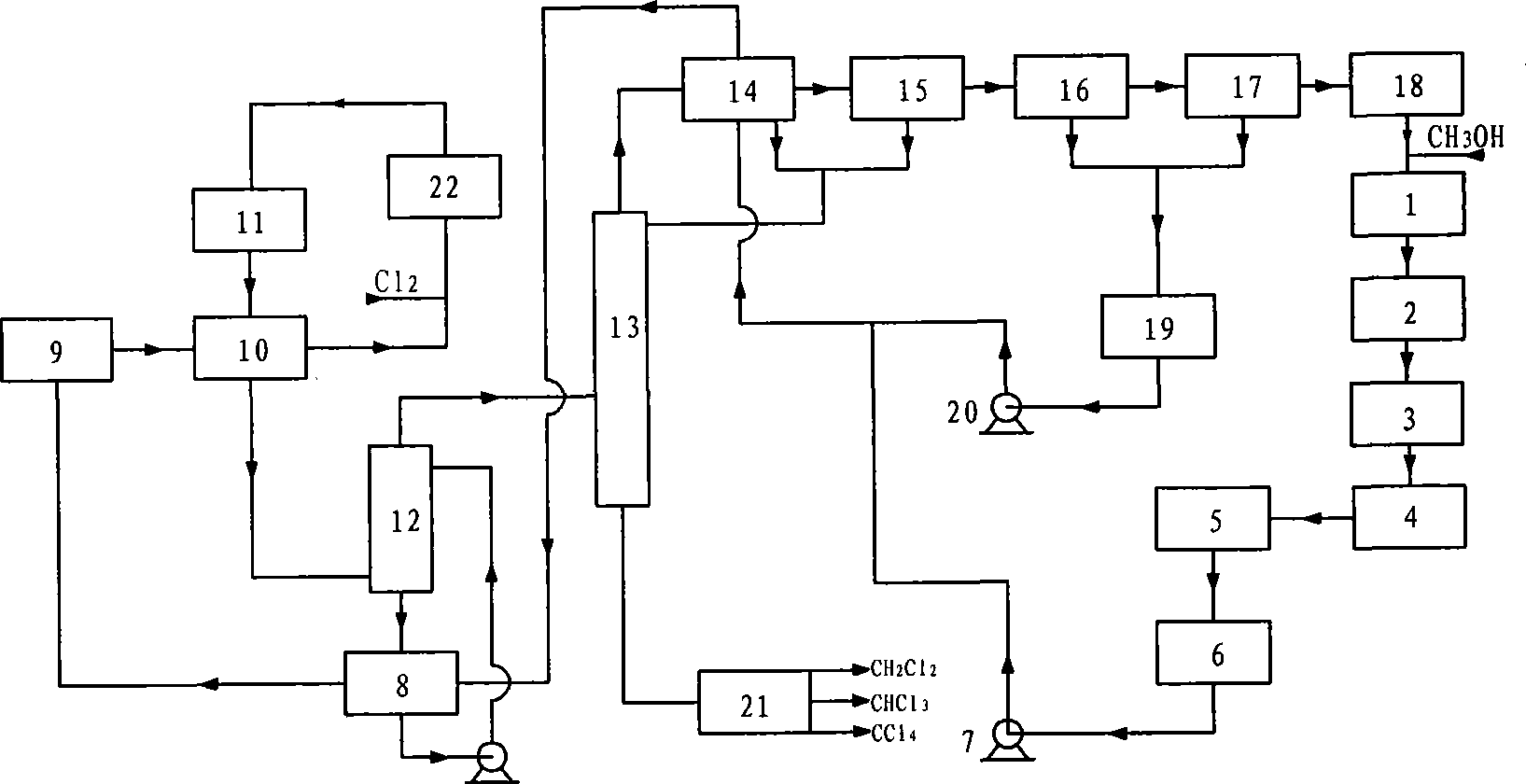

[0026] Such as figure 2 As shown, the difference between the methane chloride production process utilizing the heat of chlorination reaction of the present embodiment and the first embodiment is that an improved chlorination reactor is adopted and between the three-stage heat exchanger 10 and the chlorination reactor 11 Added heater 22 between.

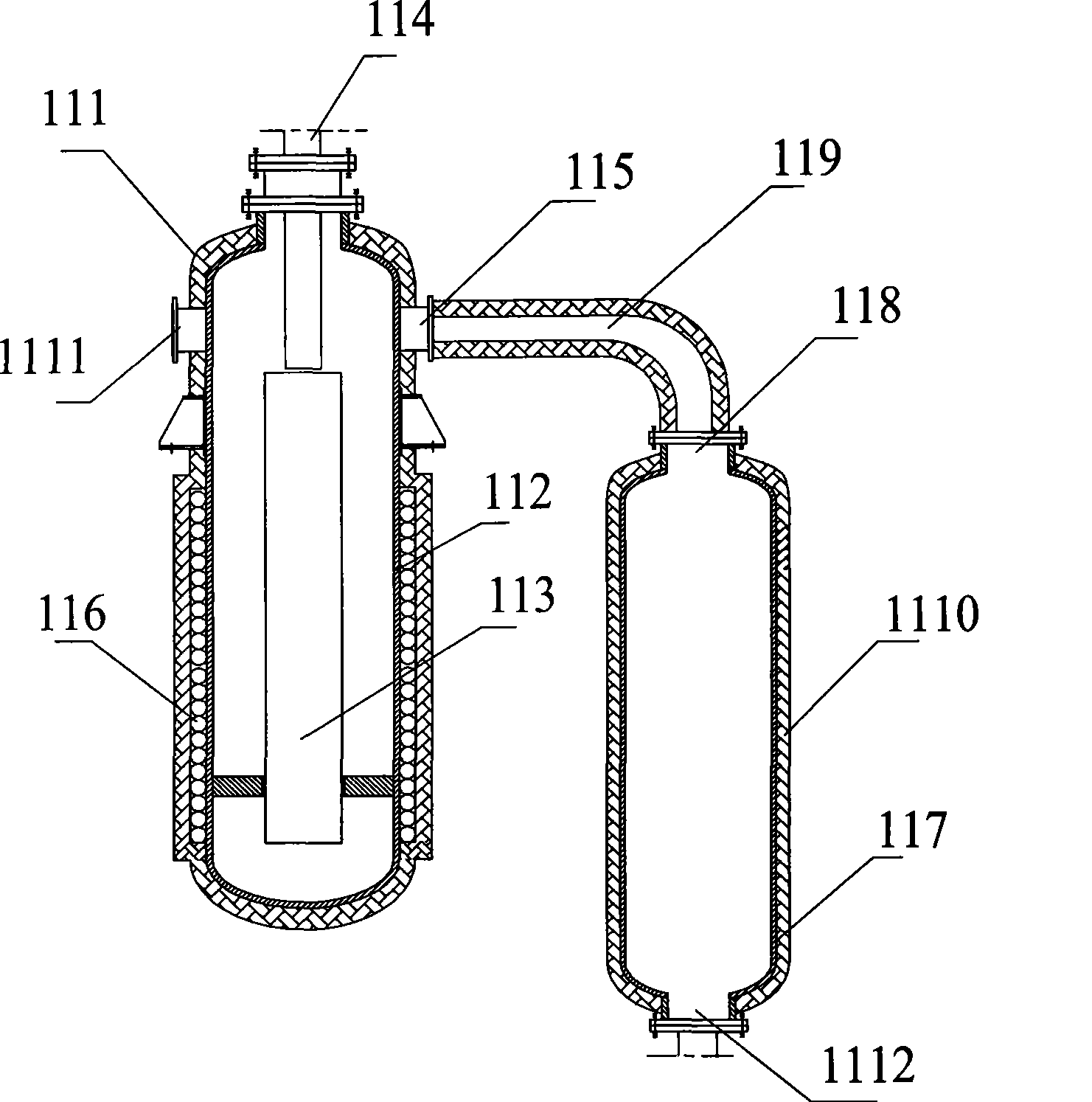

[0027] Such as image 3 As shown, the improved chlorination reactor includes a primary reaction device 111 and a secondary reaction device 117, and the primary reaction device 111 includes a reaction cylinder 112, an inlet preheating conduit 113, an air inlet pipe 114, and is arranged on the reaction cylinder 112. The air outlet 115 and the heating and heat preservation device 116 on the top, the intake preheating conduit 113 are longitudinally arranged in the reaction cylinder 112, and the inlet of the intake preheating conduit 113 is arranged correspondingly to the inlet of the reaction cylinder 112; the secondary reaction device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com