Resin composition, method for producing the same and molded article

A resin composition, the technology of the composition, applied in the field of resin composition, can solve the problems such as no disclosure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0272] (Preparation method of resin composition)

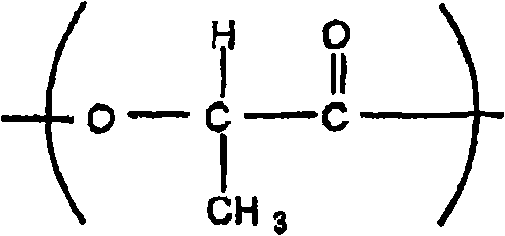

[0273] The resin composition of the present invention can be prepared by mixing aromatic polyester (component A), polylactic acid (component B), and other components as necessary. It is preferable that the carboxyl group concentration of B component is 15 eq / ton or less. Furthermore, it is preferable that the lactide content of B component is 0-700 weight ppm.

[0274] The mixing of the A component and the B component can be performed by melt mixing, solution mixing, or the like. The mixing is preferably kneaded in a molten state in a kneader, a one-shaft kneader, a two-shaft kneader, a melting reactor, or the like.

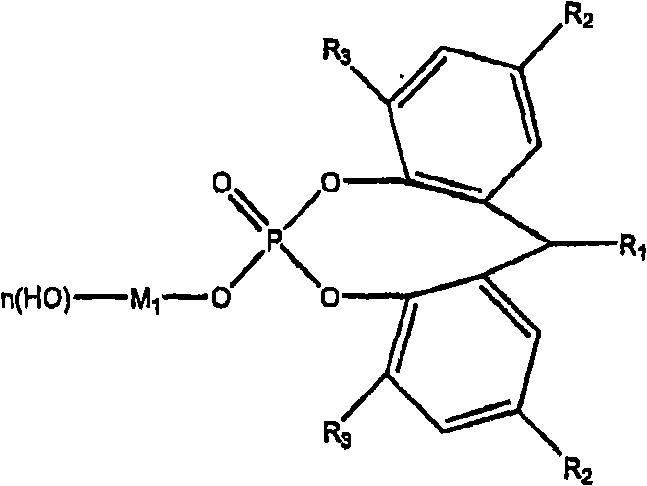

[0275] The kneading temperature may be any temperature as long as the two components are melted, but considering the stability of the resin, etc., it is preferably kneaded in the range of 230 to 280°C, more preferably in the range of 230 to 260°C. When kneading, it is preferable to use a solubilizer (compatibi...

Embodiment

[0283] The present invention will be further specifically described below through examples, but the present invention is not limited thereto.

[0284] 1. Resin

[0285] As PBT, use ゥィンテ ッ コポリマ Co., Ltd. "ji ュ Lane ッ クス2002".

[0286] 2. The physical properties of polylactic acid were measured by the following methods.

[0287] (1) Melting point (Tm), glass transition point (Tg)

[0288] In the present invention, the melting point (Tm) and glass transition temperature (Tg) are measured using DSC (manufactured by TA Instruments Co., Ltd., TA-2920) to measure the melting peak and the inflection point of heat capacity when the temperature is raised at 20°C / min.

[0289] (2) Weight average molecular weight (Mw)

[0290] The weight-average molecular weight (Mw) was measured by packing a Shodex column GPC-804L in a GPC device Alliance manufactured by Waters, dissolving 50 mg of a sample in 5 ml of a mixed solvent of chloroform and HFIP, and developing with chloroform at 40°C. ...

manufacture example 1 and 2

[0364] Production examples 1 and 2 (preparation of poly-L-lactic acid: PLLA1, 2)

[0365] Add 0.005 parts by weight of tin octoate to 100 parts by weight of L-lactide (manufactured by Musashino Chemical Research Institute Co., Ltd., optical purity 100%), and in a nitrogen atmosphere, in a reactor with stirring blades, at 180 ° C React for 2 hours. Thereafter, the remaining lactide was removed at 13.3 kPa to fragment it to obtain poly-L-lactic acid. Table 1 shows the physical properties of the obtained poly-L-lactic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com