Coal-firing agricultural soil hot water sterilization machine

A coal-burning and hot-water technology, applied in the field of coal-fired soil hot water sterilizers, can solve problems such as high cost, high application cost, and high toxicity, and achieve soil fertility restoration, high coal-burning efficiency, and high heat utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

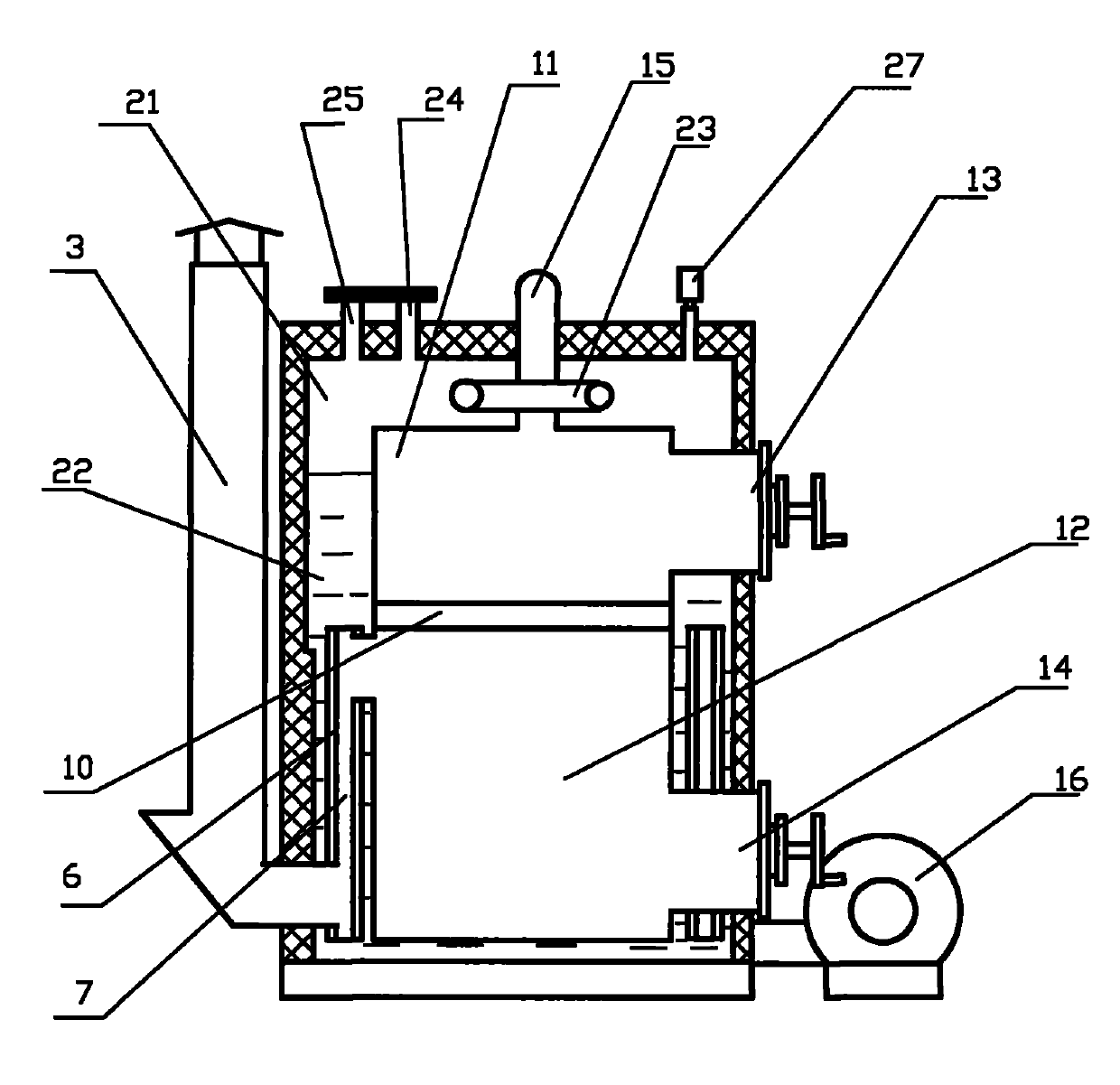

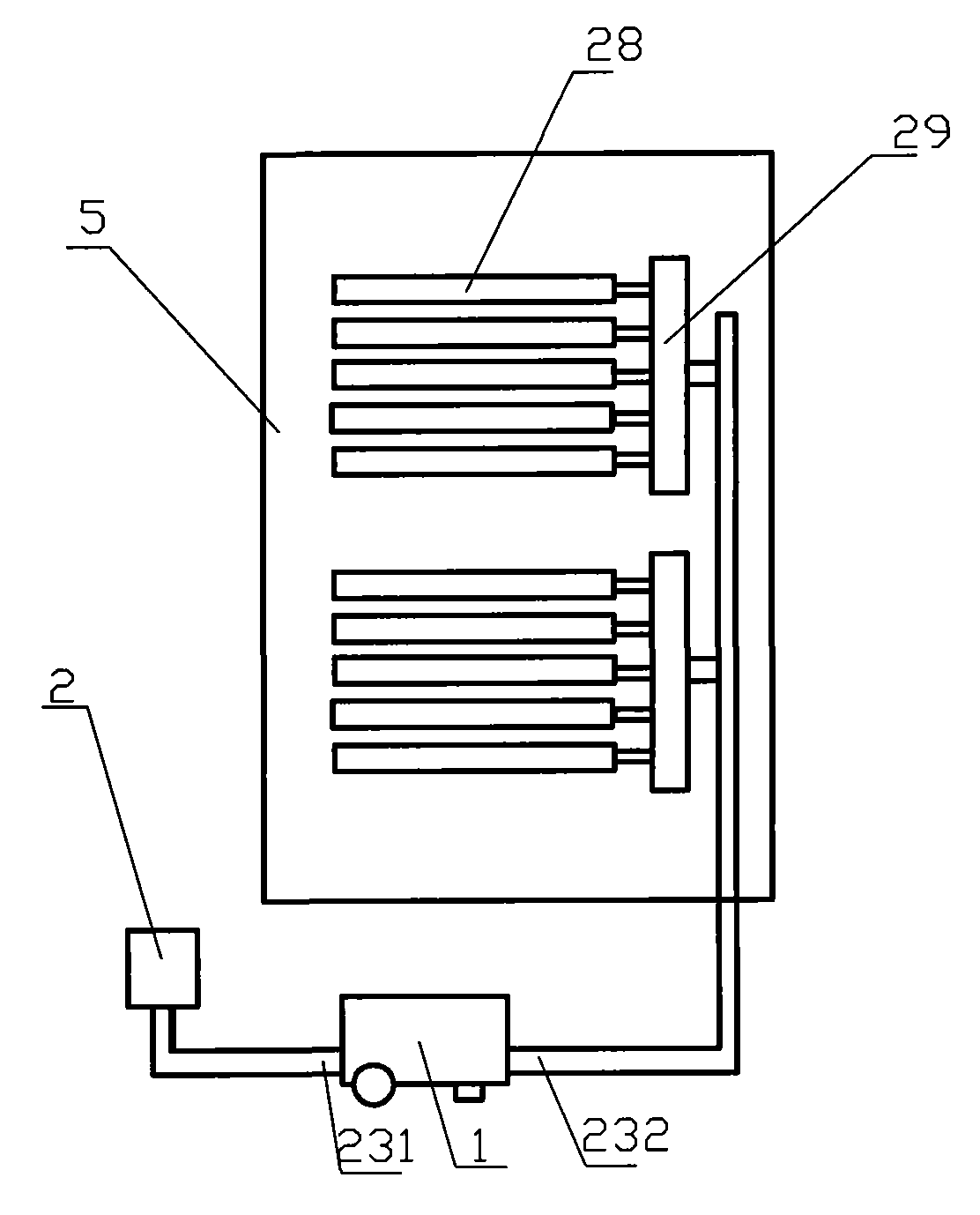

[0030] like figure 1 , figure 2 As shown, the coal-fired agricultural soil hot water disinfection machine of the present invention includes a furnace and a drum arranged outside the furnace, and the furnace is divided into a coal chamber 11 at the upper part and a fire chamber at the lower part by a negative pressure water tube type grate 10. Chamber 12, the top of the coal chamber 11 is connected with an air inlet pipe 15, the air inlet pipe 15 is connected with an external fan 16, the coal chamber 11 adds coal fuel through the coal filling port 13, and the fire chamber 12 passes through the ash outlet on one side 14 can clean up the ash produced by coal burning; the drum includes a lower water space 22 and an upper negative pressure vacuum space 21, and the negative pressure vacuum space 21 is provided with a heat exchange tube 23 communicating with the outside. The vacuum space 21 is in a vacuum state under normal conditions; there are two rows of heated tube bundles 6 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com