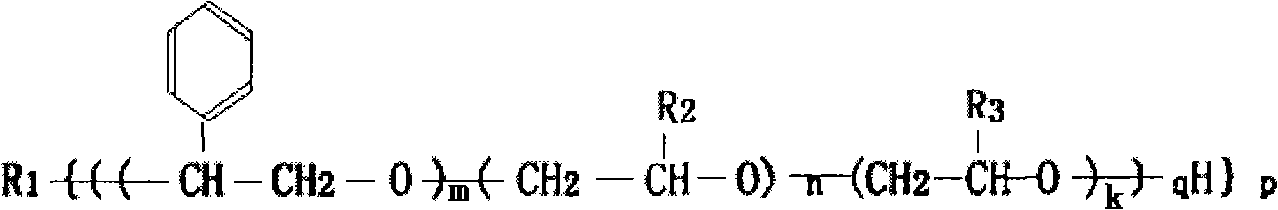

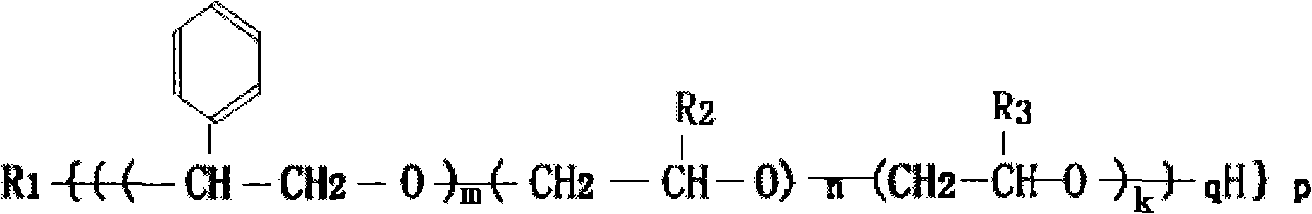

Novel polyether containing styrene oxide opened loop repetitive units and method for preparing the same

A technique for oxidizing styrene and repeating units, which is applied in the field of new polyethers and its preparation, can solve the problems of time-consuming synthesis methods, lack of styrene oxide monomers, and inability to realize industrialization, etc., and achieves simple synthesis methods and low preparation costs , good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: 1 mol of polyoxypropylene with a molecular weight of 400 (the equivalent of hydroxyl value is 200) is stirred and added with a cobalt-zinc double metal cyanide catalyst with a total charge of 0.005%, and under nitrogen protection, the reaction temperature is 140°C, and 10 mol of styrene oxide is added dropwise , the dropwise addition is completed and the insulation aging reaction is carried out for 0.5 hours. At 140°C, the vacuum degree is greater than 93kPa, and the vacuum is pumped for 0.5 hours. Then the vacuum is stopped and then 0.3% of the total amount of analytically pure potassium hydroxide is added under nitrogen protection. At 140°C, The vacuum degree is greater than 93kPa, vacuumize for 0.5 hours, stop the vacuum, add 72.73mol ethylene oxide dropwise, the reaction temperature is 140°C, after the dropwise addition, keep the heat preservation and aging reaction for 0.5 hours, at 140°C, the vacuum degree is greater than 93kPa, vacuumize for 0.5 hours, s...

Embodiment 2

[0033] Embodiment 2: 1mol molecular weight is the glycerol polyoxypropylene ether (hydroxyl value equivalent is 167) of 500 and stirs and adds the xylene of total charge 35%, stirs and adds the cobalt-zinc double metal cyanide catalyst of total charge 0.005%, nitrogen protection At a reaction temperature of 140°C, 30mol styrene oxide was added dropwise, and after the dropwise addition, the heat preservation and aging reaction was carried out for 0.5 hours. At 150°C, the vacuum degree was greater than 93kPa, the steam was heated up, and the xylene was removed by vacuuming. When the temperature rose to 155°C, stop Vacuum, cool down to 80°C, and filter to obtain the finished product. The molecular weight of the product is 4100.

Embodiment 3

[0034] Embodiment 3: 1mol molecular weight is the glycerol polyoxypropylene ether (hydroxyl value equivalent is 167) of 500 and stirs and adds the xylene of total charge 35%, stirs and adds the cobalt-zinc double metal cyanide catalyst of total charge 0.005%, nitrogen protection At a reaction temperature of 140°C, 30mol of styrene oxide was added dropwise, and after the dropwise addition, the heat preservation and aging reaction was carried out for 0.5 hours. Then, under the protection of nitrogen, 0.3% of the total amount of analytically pure potassium hydroxide was added, and 20mol of ethylene oxide was added dropwise, and the reaction temperature was 140°C. ℃, heat preservation and aging reaction for 0.5 hours after the dropwise addition, lower the temperature to 80 ℃, add phosphoric acid aqueous solution equivalent to potassium hydroxide to neutralize for 0.5 hours, add magnesium silicate adsorbent, raise the temperature to 150 ℃, the vacuum degree is greater than 93kPa, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com