Suspension suitable for animal directly-drinking and preparation method thereof

A technology of suspension and dry suspension, which is applied in the direction of medical preparations with non-active ingredients, medical preparations containing active ingredients, and pharmaceutical formulas, which can solve problems such as low bioavailability and unstable quality, and achieve Uniform drug dispersion, convenient administration, and improved release volume and release rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

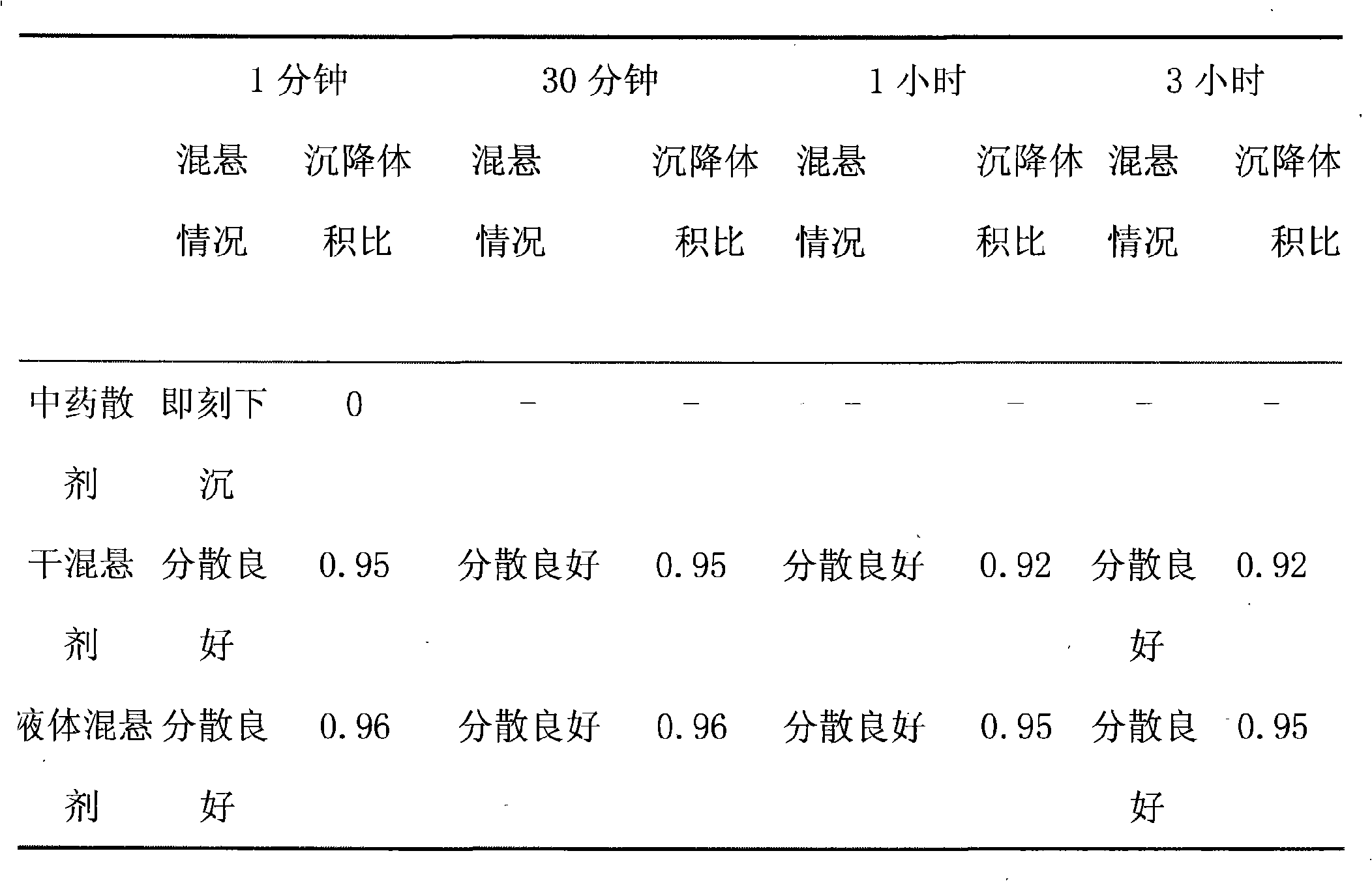

Image

Examples

Embodiment 1

[0034] Make Qingresan into dry suspension

[0035] A. Mix 60g of Daqingye, 60g of Radix Radix, 60g of gypsum, 30g of rhubarb, and 60g of xuanming powder, and pulverize them so that the particle size distribution is 1-15 μm, and set aside.

[0036] B. Weigh 0.5 g of xanthan gum, 0.1 g of sodium lauryl sulfate, and 0.8 g of magnesium stearate, grind them to 15 μm respectively, and mix them for later use.

[0037] C. Mix the products of step A and step B evenly, and pack them separately.

Embodiment 2

[0039] Make key chicken powder into dry suspension

[0040] A. Mix Codonopsis 20g, Astragalus 20g, Poria cocos 20g, Liushenqu 10g, malt 10g, hawthorn (fried) 10g, licorice 5g, betel nut (fried) 5g, pulverize to make the particle size distribution 5-15μm, set aside.

[0041] B. Weigh 0.3 g of hydroxypropyl methylcellulose, 0.06 g of sodium lauryl sulfate, and 2 g of micropowdered silica gel, grind them to 15 μm, mix and set aside.

[0042] C. Mix the products of step A and step B evenly, and pack them separately.

Embodiment 3

[0044] Make Pulsatilla powder into dry suspension

[0045] A. Mix 60g of Pulsatillae Radix, 30g of Coptidis Rhizoma, 45g of Phellodendron Phellodendron, and 60g of Bark Peel, and grind them to make the particle size distribution 5-15μm.

[0046] B. Weigh 0.5g of carbomer, 0.2g of sodium lauryl sulfate, 0.2g of magnesium stearate, 0.3g of sodium carboxymethyl starch, and 0.3g of hydroxypropyl methylcellulose, and pulverize them to 15 μm respectively. spare.

[0047] C. Mix the products of step A and step B.

[0048] D. Dissolve 1g of sodium carboxymethylcellulose in 300ml of purified water, stir evenly, and then add to the mixture of A and B to prepare a soft material.

[0049] E. Pass through a 20-mesh sieve to granulate, dry at 55-60°C;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com