Manufacturing method of glass substrate for flat glass

A glass substrate, flat glass technology, applied in the manufacture of discharge tubes/lamps, ships or lead-in wires, glass production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

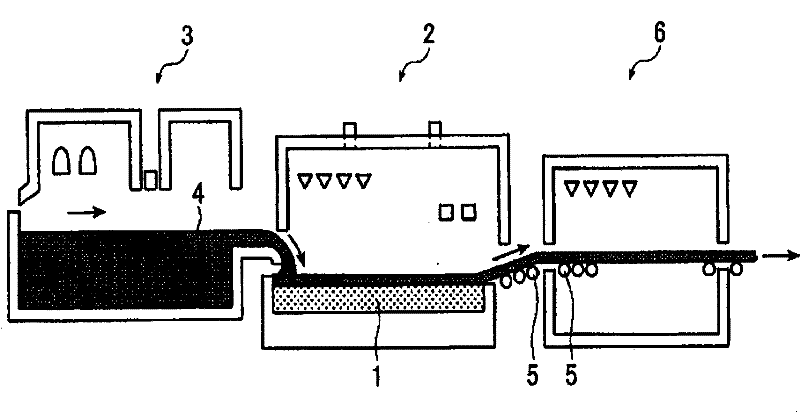

[0145] use figure 2 The experimental setup is shown. figure 2 is a cross-sectional view of a large tube furnace used in Examples.

[0146] Specifically, a quartz tube 12 is installed in a large-scale tube furnace 11 capable of adjusting the temperature, a glass substrate 13 (10 cm square) for flat glass with a thickness of 2.8 mm is placed in the quartz tube 12, and the large-scale tube furnace 11 is heated to 600 ℃. Among them, "glass substrate for flat glass" is expressed as SiO by mass percentage of oxide standard 2 : 58.6, Al 2 o 3 : 6.9, MgO: 1.9, CaO: 4.8, SrO: 6.9, BaO: 7.9, Na 2 O: 4.0, K 2 O: 6.1, ZrO 2 : 2.8, Fe 2 o 3 : Glass with a composition of 0.09. In addition, the glass transition temperature of the said glass is 600 degreeC.

[0147] Then, the sodium tetraborate decahydrate reagent 15 added to the alumina boat 14 was vaporized by locally heating it to 850° C., and the vaporized substance was sprayed from the end of the quartz tube in the direction...

Embodiment 2

[0151] In addition to making SO 2 The gas injection volume is 0.4L / m 2 Except that, the glass substrate for plate glass with a protective film was manufactured by the method similar to Example 1.

Embodiment 3

[0153] In addition to making SO 2 The gas injection volume is 1.0L / m 2 Except that, the glass substrate for plate glass with a protective film was manufactured by the method similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com