Gluconobacter oxydans and method for preparing ketoxylose using the same

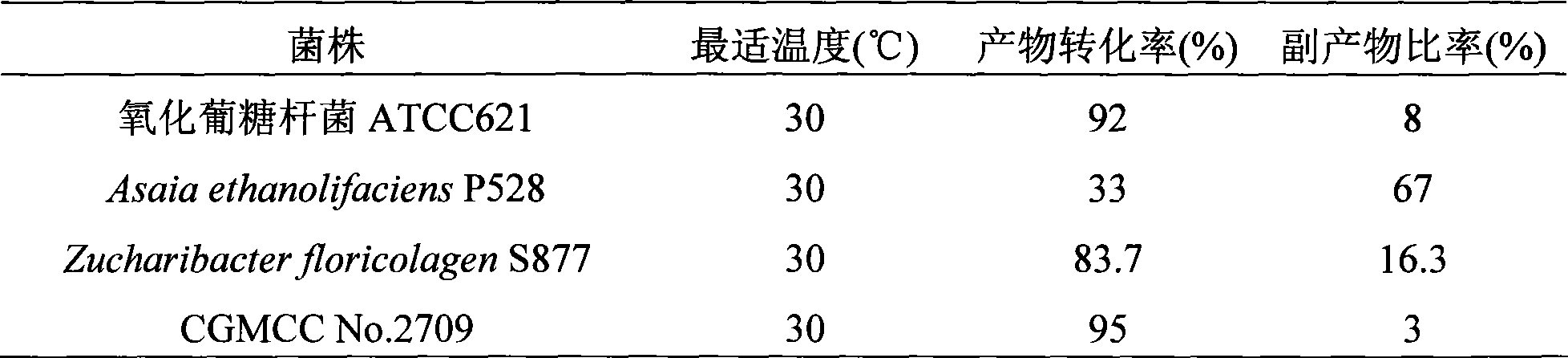

A technology of Gluconobacter oxydans and xylulose, which is applied in the fields of fermentation engineering and enzyme engineering, can solve the problems such as non-recyclable utilization, unfavorable product separation and purification, and increased production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Incline medium: glucose 30g / L, yeast extract 10g / L, beef extract 5g / L, agar 20g / L.

[0045] Shake flask medium: glucose 30g / L, yeast extract 25g / L, beef extract 5g / L, D-arabitol 10g / L, KH 2 PO 4 5g / L.

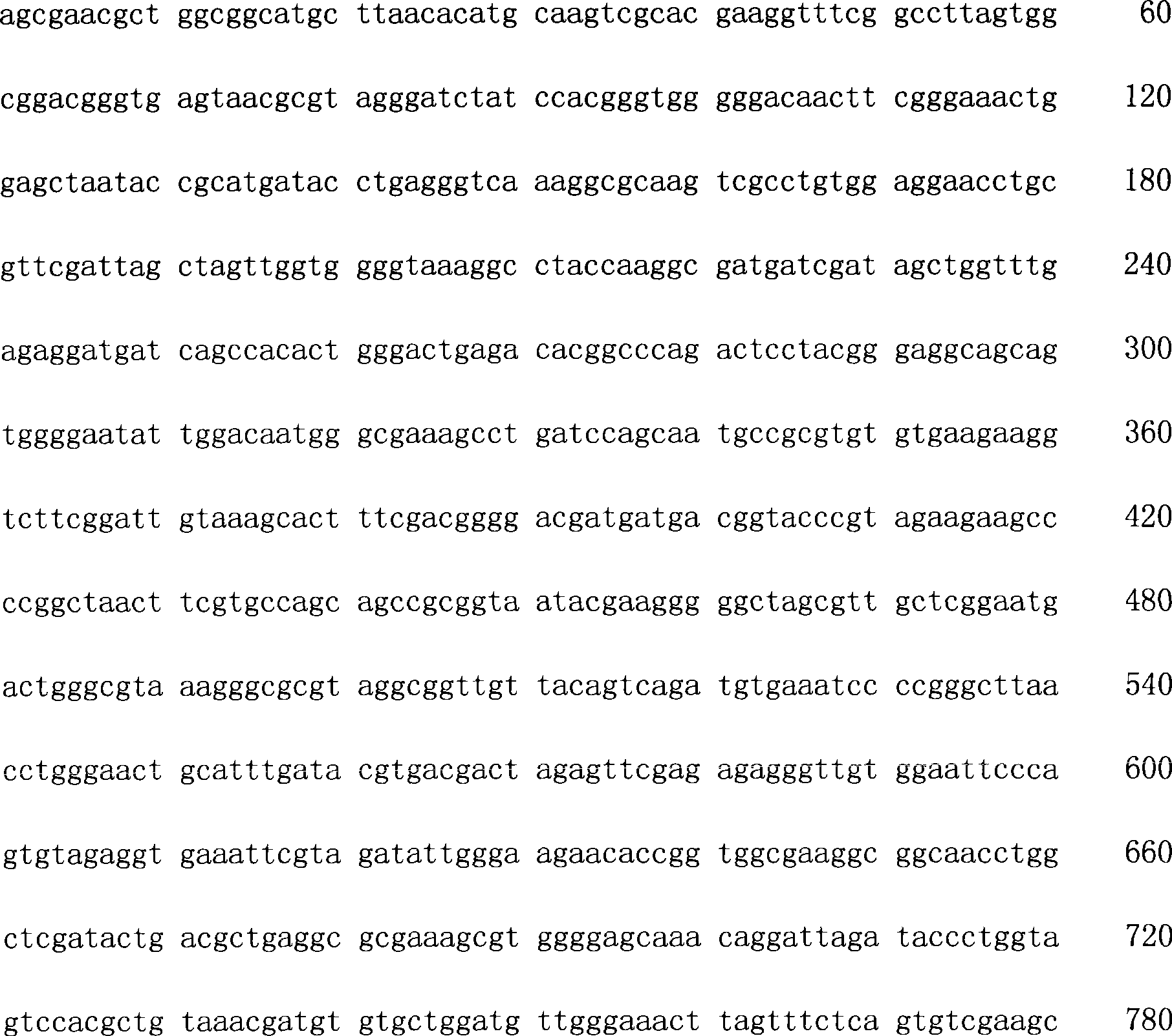

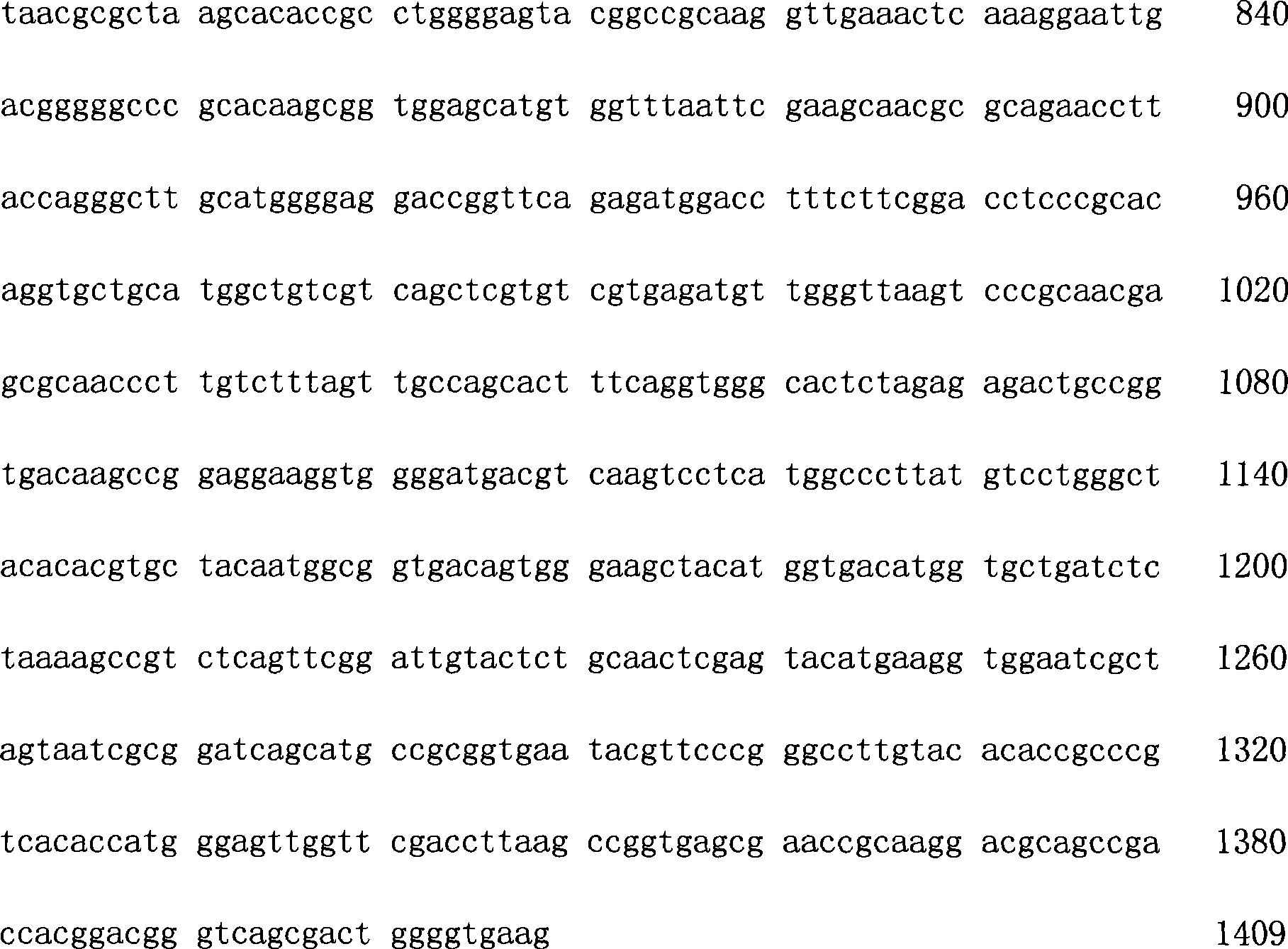

[0046] Cultivate Staphylococcus oxidans CGMCC No.2709 on a slant medium at 30°C for 24 hours, then put a ring of this bacteria in the shake flask medium, cultivate it at 30°C for 10 hours, and the shake flask rotates at a speed of 200r / min. The content of D-ara is 20g / L, and the enzyme production is 2.5~5.0U / mL. It is transformed by free cells. Weigh 1g of wet cells after centrifugation and add them to 10mL of 30g / L D-ara solution (the amount of cells added is calculated as per 100g of cells transformed 1L of 30g / L D-ara solution), under the condition of 30°C, stir and oscillate in a shaker flask (rotating speed 120r / min) to convert and produce D-xylulose. The reaction time is 9h. After the reaction is terminated, the substrate conversion rate and product concentratio...

Embodiment 2

[0048] With 30g / L maltose as the carbon source, 20g / L yeast extract, and 10g / L bean cake powder as the nitrogen source, the other components of the medium and the cell culture conditions are the same as in Example 1, and a 1.5% sodium alginate colloid solution is prepared, and the physiological After mixing the bacterial suspension prepared with saline evenly, add 8% diatomaceous earth for adsorption, and drop 2% CaCl with a syringe 2 Solidify in the solution to make spherical immobilized cells with a diameter of about 3-4mm, and put them in a refrigerator at 4°C for several hours, then pour off the supernatant, wash twice with distilled water, and replace 1g of the centrifuged wet cells with seaweed 5 g of immobilized cells were obtained by embedding in sodium phosphate, and transformed into 10 mL of 50 g / L D-arabitol solution in a shake flask at 30°C (rotating speed: 200 r / min). The transformation time for each batch was 13 hours, and 30 batches were transformed. , the avera...

Embodiment 3

[0050] Glucose 225g, yeast extract 112.5g, beef extract 22.5g, D-arabitol 45g, KH 2 PO 4 22.5g, pH 5.0, dilute to 4.5L with water, make culture medium, put into 7.5L stirring fermenter, steam sterilize at 121℃ for 15min. Prepare seed medium: glucose 30g / L, yeast extract 10g / L, beef extract 5g / L. Put Gluconobacter oxydans CGMCCNo.2709 in the seed medium one by one, and culture it at 30°C for 8 hours to obtain the seed liquid. Put the seed liquid into the cooled fermentation medium according to the inoculation amount of 3% of the volume of the fermentation liquid, and cultivate it at 30°C. (Ventilation 0.7vvm, stirring speed 600r / min) 48h. The fermented liquid is subjected to bacterial filtration treatment in an ultrafilter, and the molecular weight cut-off of the ultrafiltration membrane is 10 6 Da, the operating pressure is 0.2MPa, the temperature is controlled at 50°C, and the membrane surface velocity is 4m / s. After immobilizing the 100g bacterium obtained by interceptio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com