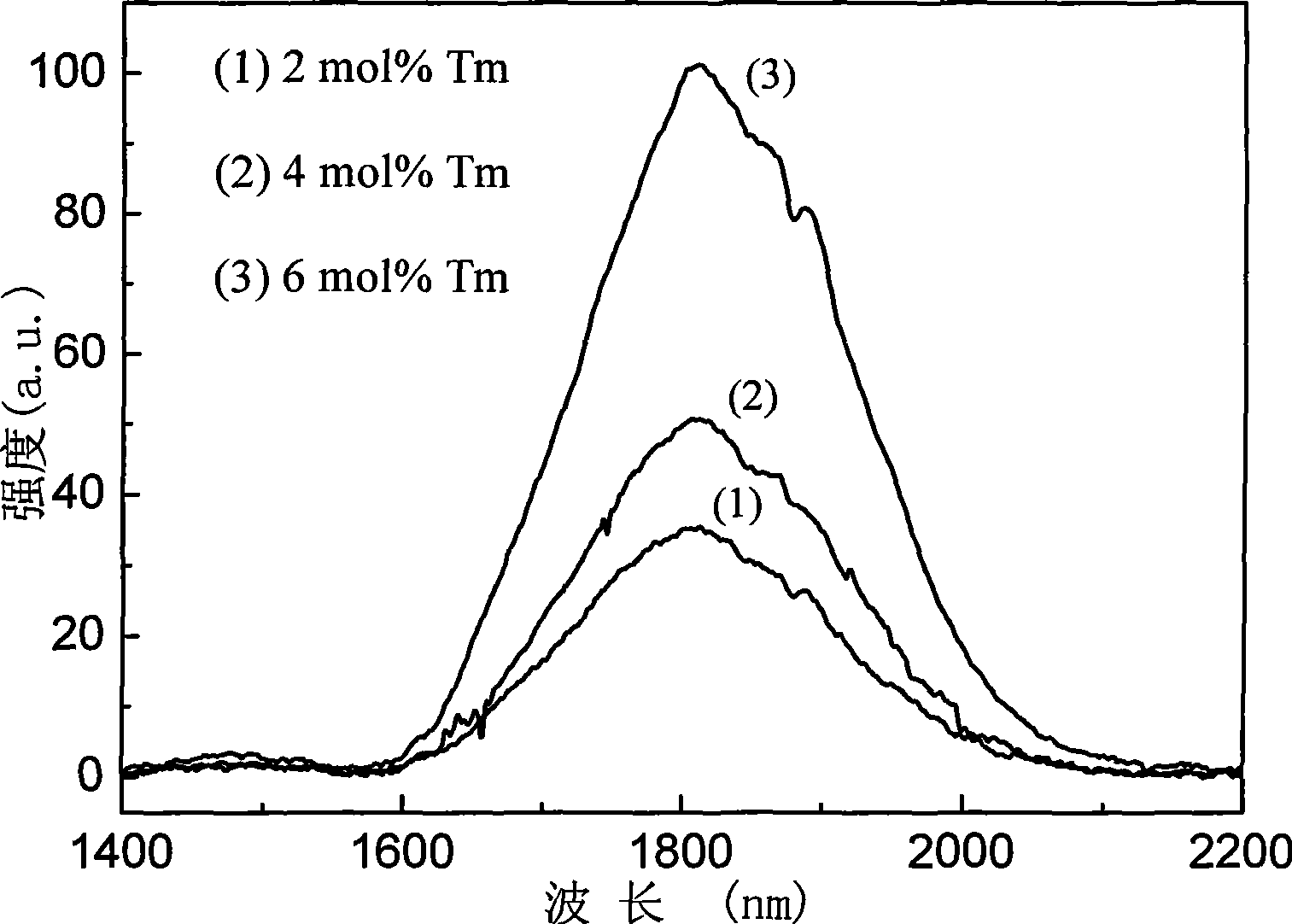

2 mu m high thulium doped fluorphosphate glass optical fiber and preparation thereof

A technology of fluorophosphate glass and thulium fluorophosphate, which is applied in glass manufacturing equipment, manufacturing tools, etc., to achieve the effects of good mechanical strength, low production cost, and simple preparation and drawing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

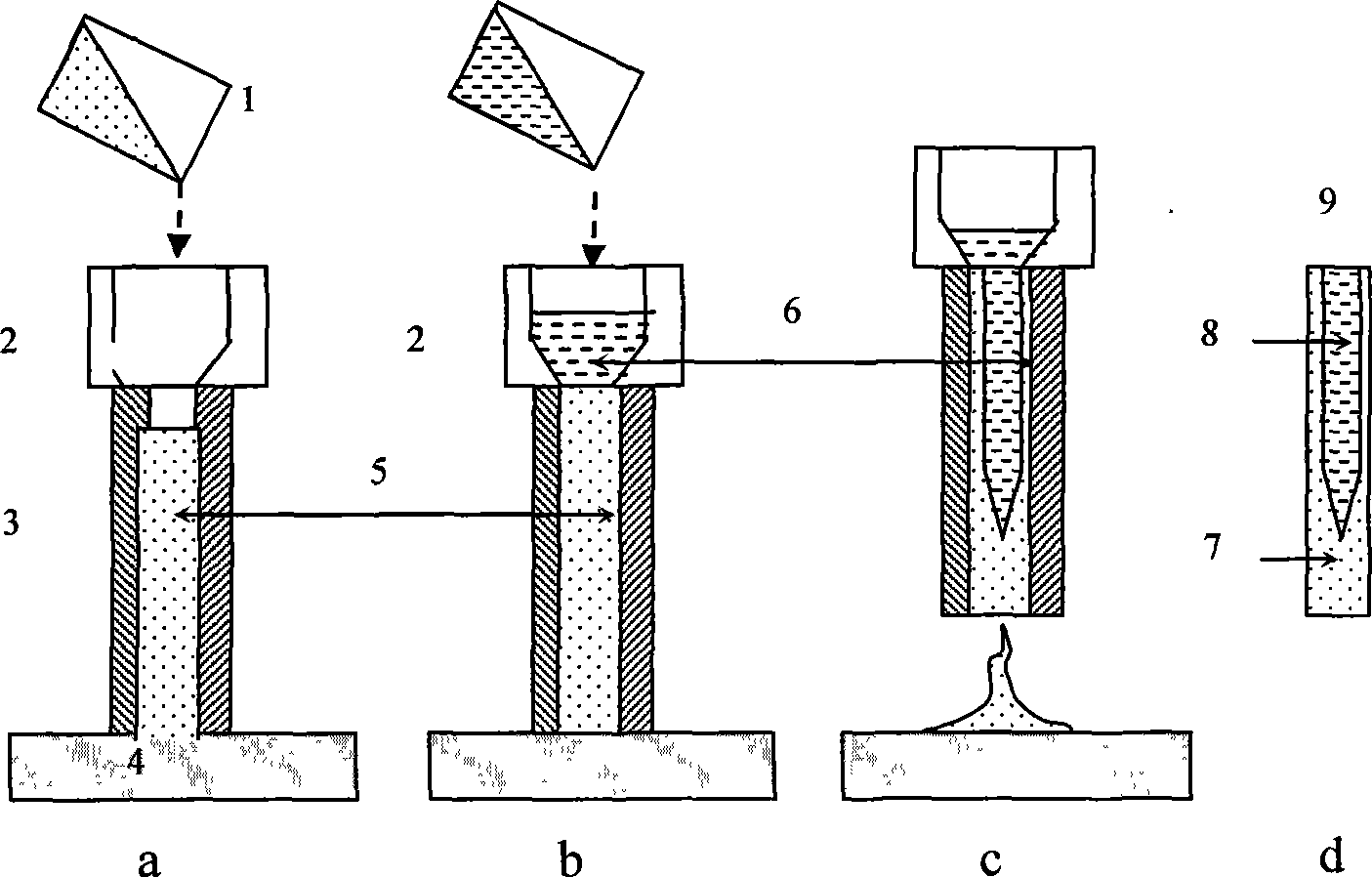

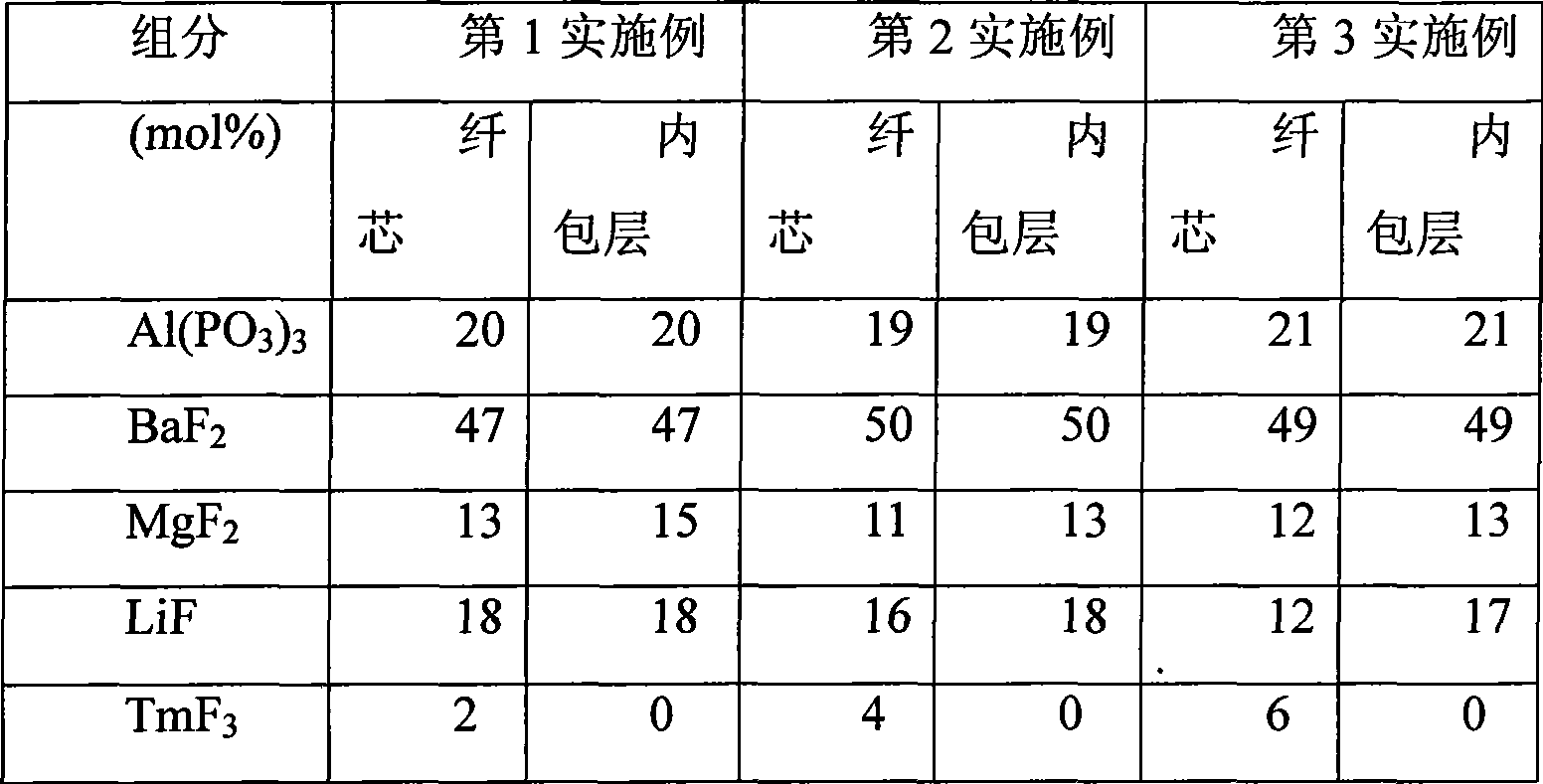

[0048] The preparation method of 2 μm highly doped thulium fluorophosphate glass optical fiber of the present invention comprises the following steps:

[0049] select the raw material formula of core glass and the raw material formula of inner cladding glass by embodiment 1;

[0050] Melting of the core glass and inner cladding glass described in :

[0051] ① Melting of the core glass: Weigh the powdered raw materials according to the formula in Example 1, mix them evenly, and put them in a platinum crucible and melt them in a silicon carbide rod electric furnace. The melting temperature is 1020-1100 °C. After homogenization and clarification, the core glass melt is ready to be released at 800-1000°C;

[0052] 2. Melting of the inner cladding glass: weigh each powdery raw material according to the formula in Example 1, the melting process of the inner cladding glass is exactly the same as the melting process of the core glass, the inner cladding glass melt Prepare to be bak...

example 2

[0061] The raw material formulations of Example 2 and Example 3 are shown in Table 1, and the melting process of the core material and inner cladding glass is the same as that of Example 1 above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com