Conductive particles, adhesive composition, circuit connection material and connection structure, as well as connection method of circuit member

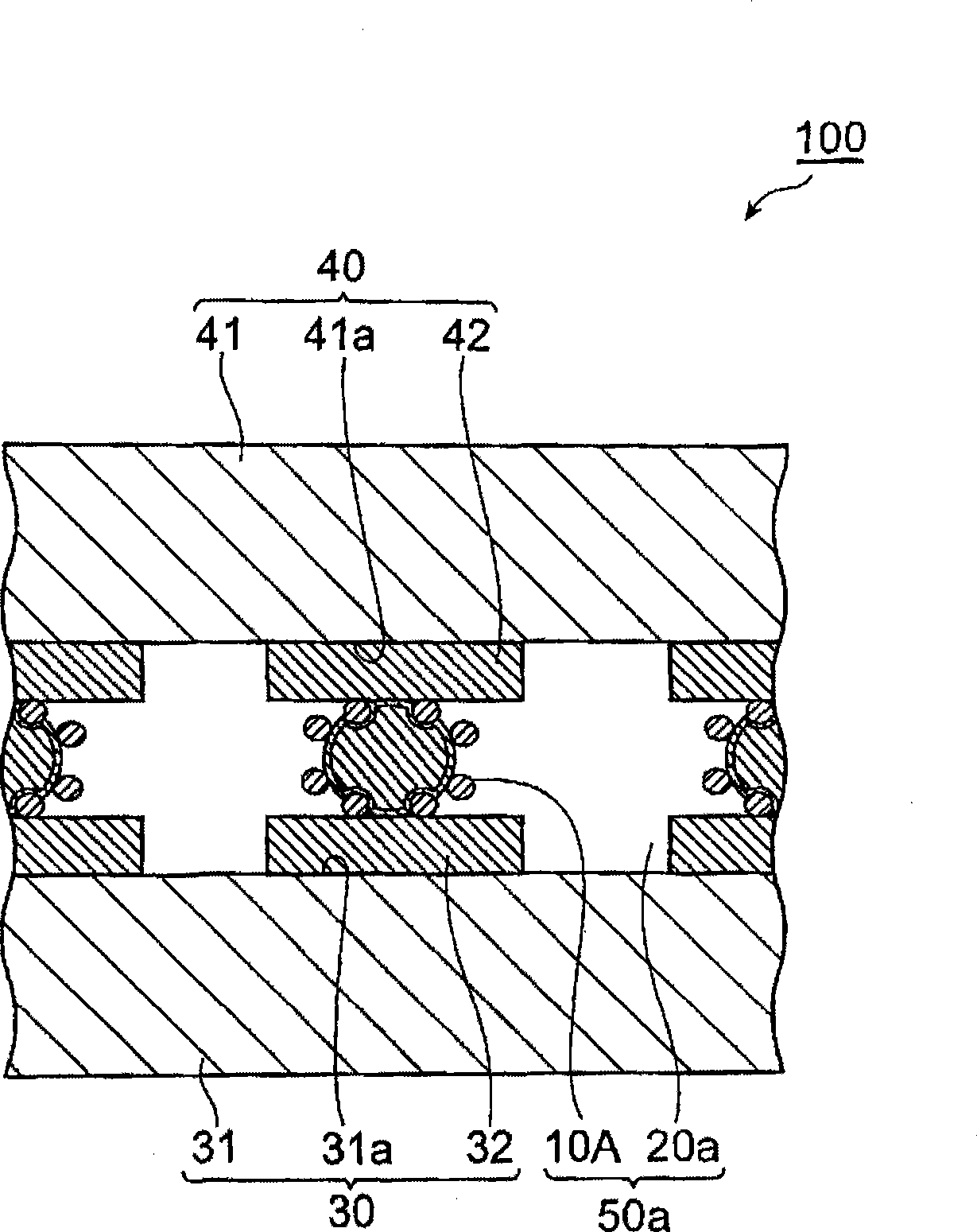

A technology of circuit connection materials and conductive particles, which is applied in the direction of conductive adhesives, conductive materials dispersed in non-conductive inorganic materials, and printed circuits assembled with electrical components, which can solve the problem of increased resistance value of connected parts and the number of conductive particles. Insufficient, insufficient insulation between adjacent circuit electrodes, etc., to achieve the effect of suppressed resistance value, low initial resistance value, and excellent insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0130] Conductive core particles were produced by the following method. That is, cross-linked polystyrene particles (manufactured by Soken Chemical Co., Ltd., trade name: SX series, average particle diameter: 4 μm) were prepared as substrate particles, and a Ni layer (thickness: 0.08 μm) was provided on the surface of the particles by electroless plating. ). Furthermore, an Au layer (thickness: 0.03 μm) was provided outside the Ni layer by electroless plating to obtain core particles having a conductive layer composed of a Ni layer and an Au layer.

[0131] As an organic polymer compound (insulating coating part) for covering the surface of the core particle, a cross-linked acrylic resin (manufactured by Soken Chemical, trade name: MP series, degree of cross-linking: 20%, gel fraction: 18%) was prepared. . 4 g of the cross-linked acrylic resin and 20 g of core particles were placed in a fine particle surface modification device (Hibrideyza—) (manufactured by Nara Machinery M...

Embodiment 2

[0148] Except that a cross-linked acrylic resin with a cross-linking degree of 10% (manufactured by Soken Chemical Co., Ltd., trade name: MP series, gel fraction: 8%) was used instead of a cross-linked acrylic resin with a cross-linking degree of 20%, the others were as in the examples. 1 Conductive particles, circuit connection materials and connection structures were fabricated. The coverage of the conductive particles was 25%.

Embodiment 3

[0150]Conductive particles, circuit connection materials, and connection structures were manufactured in accordance with Example 1, except that an insulating covering portion was formed on the surface of the core particles by the following method.

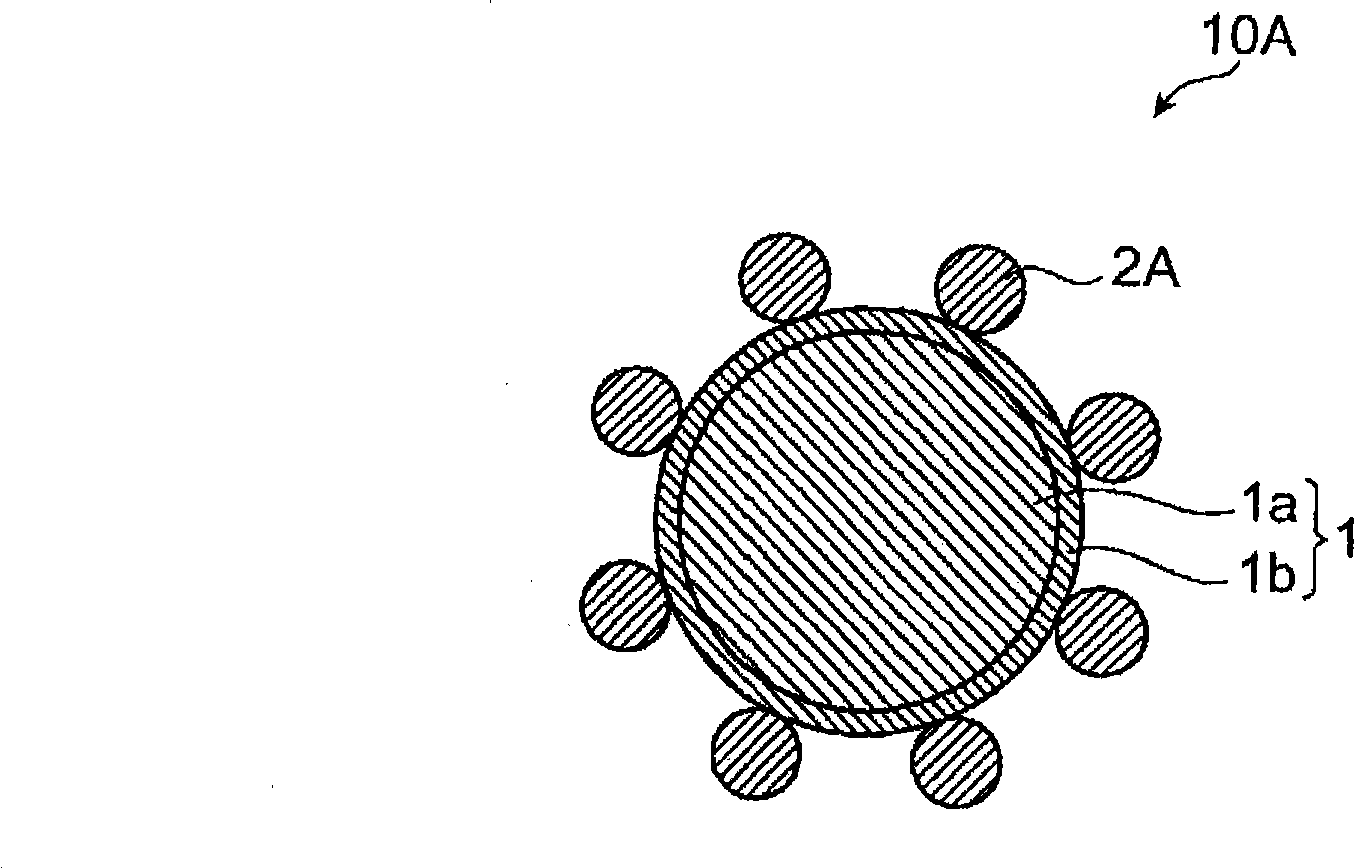

[0151] It is to put the same core particles and cross-linked acrylic resin (manufactured by Soken Chemical Co., Ltd., trade name: MP series, cross-linking degree: 10%, gel fraction: 8%) as those produced in Example 1 into the microparticle surface modification device, produced as image 3 Conductive particles of the structure shown. In addition, the processing conditions of the microparticle surface modifying device were a rotation speed of 16000 / min and a reaction tank temperature of 60°C. The coverage of the conductive particles was 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com