Assembling method for DC electric connector and DC electric connector

An assembly method and connector technology, which are applied in the assembly/disassembly of contacts, devices for reducing the stress at the connection of wires, and parts of connecting devices, etc., can solve the problem that the product shape is not easy to control, the wire protection is weak, and the production efficiency Low problems, to achieve the effect of low cost, low defective rate and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

[0019] In order to solve the problem of using spot welding between the DC connector body and the wire in the prior art, UV glue is used for curing to realize the low production efficiency during the assembly of the DC connector. The shape of the cured product is not easy to control, and the wire is easily protected by external force. The effect is weak and the overall production cost is very high. The present invention provides a DC connector assembly method.

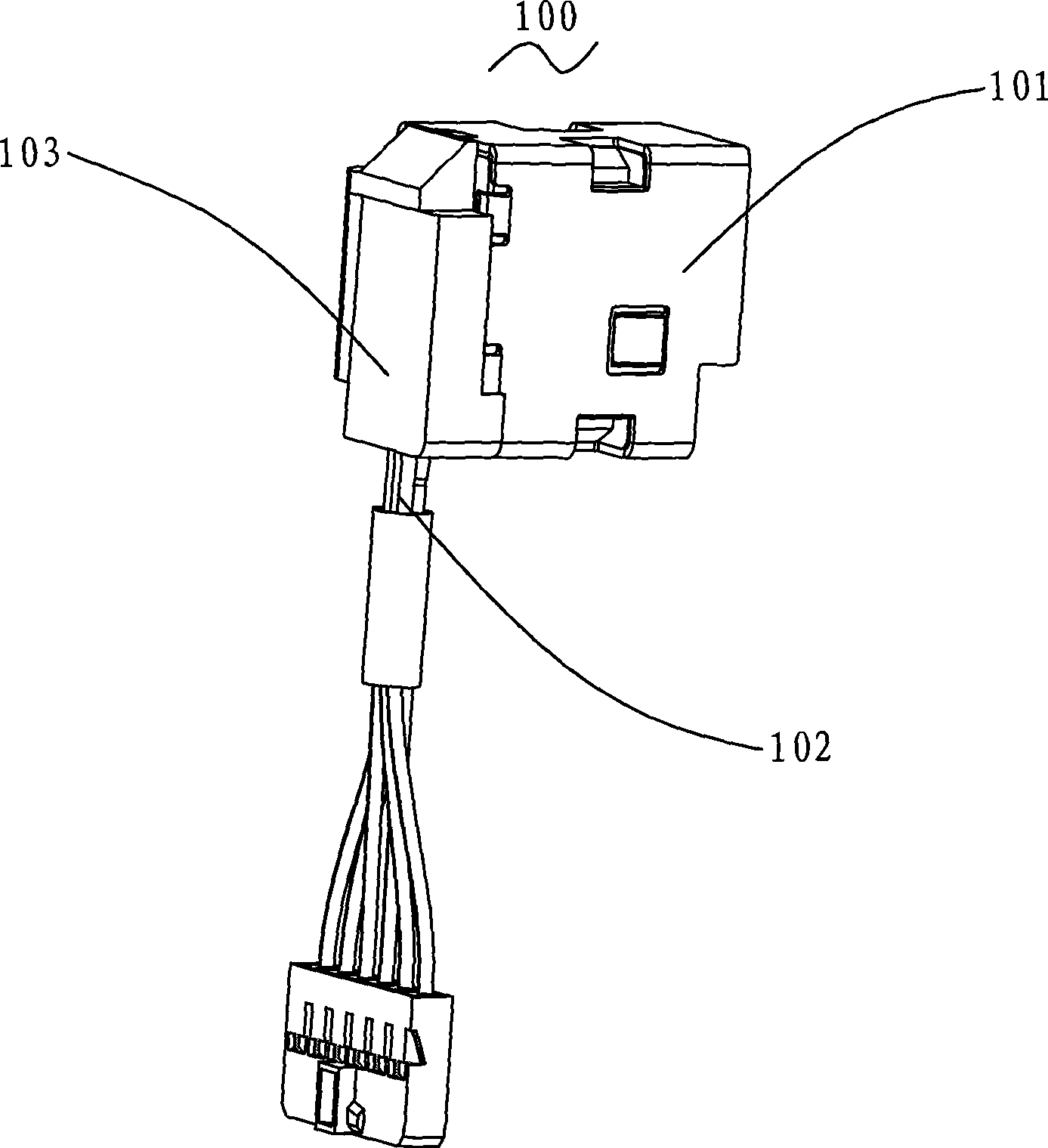

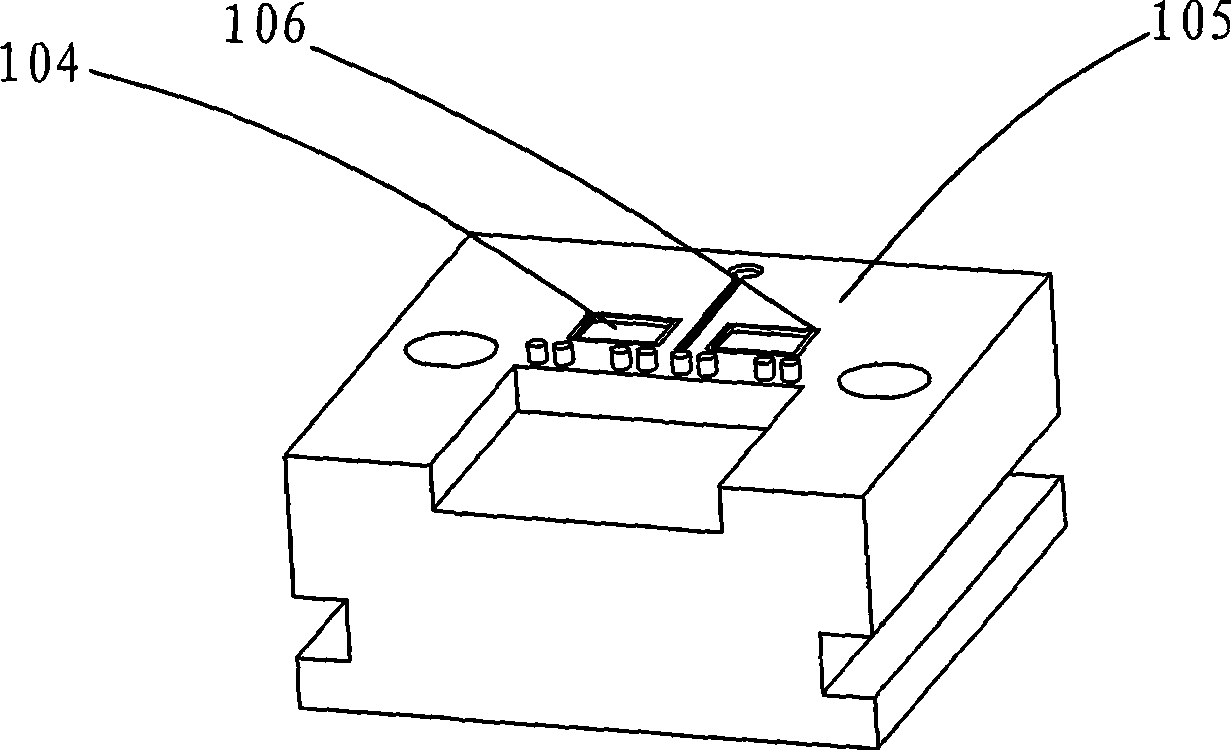

[0020] The assembling method of the DC connector specifically includes steps: first step, welding the DC connector body 101 and the wire 102; second step, welding the welded DC connector body 101 and the wire 102 Packaging is performed by low-pressure injection molding, so as to realize the assembly of the DC connector. Wherein, the second step is specifically: put the welding part of the welded DC connector body 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com