Reverse osmosis water production apparatus, water production method, and method for cleaning and maintaining reverse osmosis water production apparatus

A technology of reverse osmosis and reverse osmosis membrane, applied in osmosis/dialysis water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the lack of trace element supplementation, incomplete ion content, and negative effects on health And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

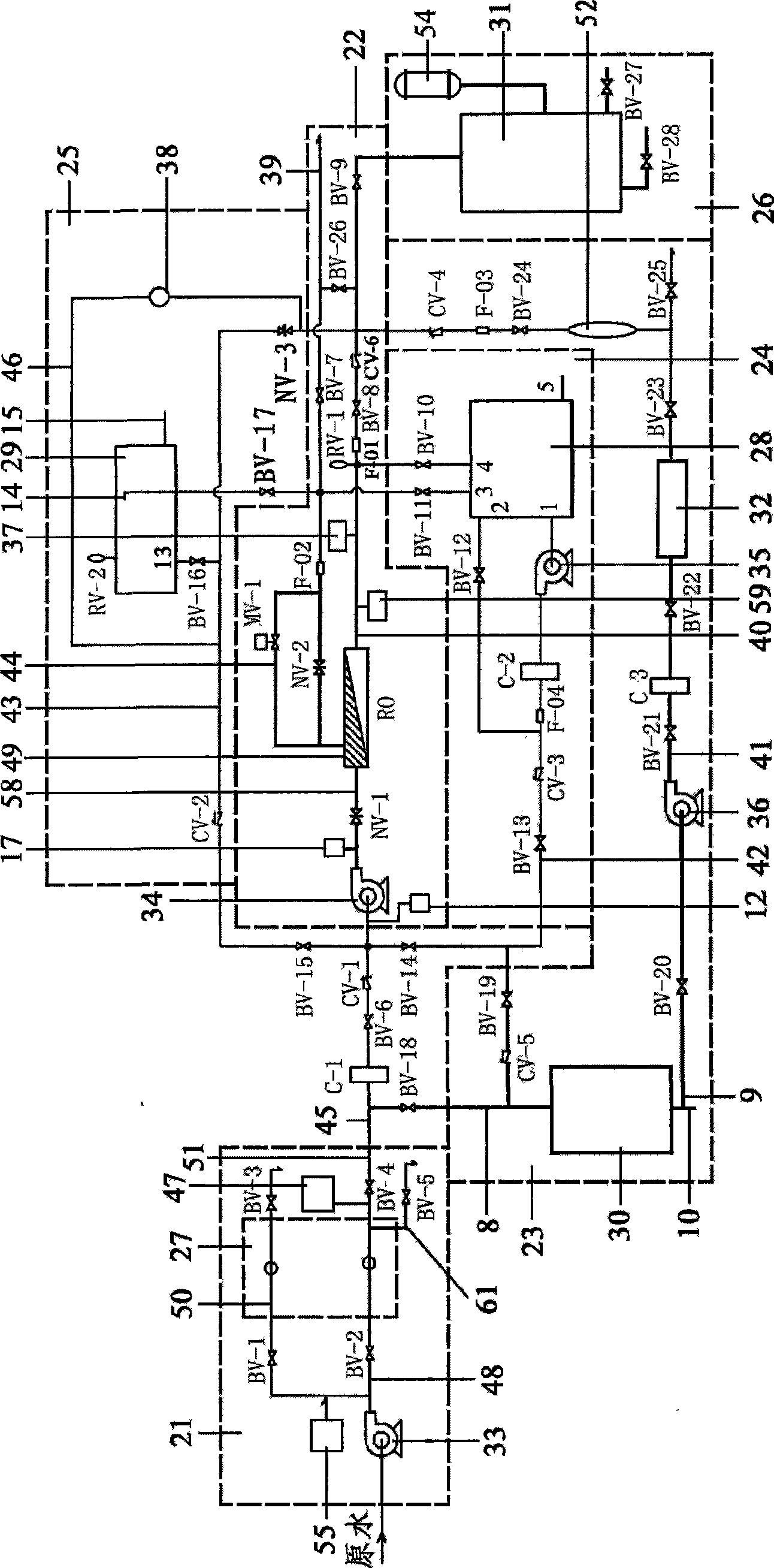

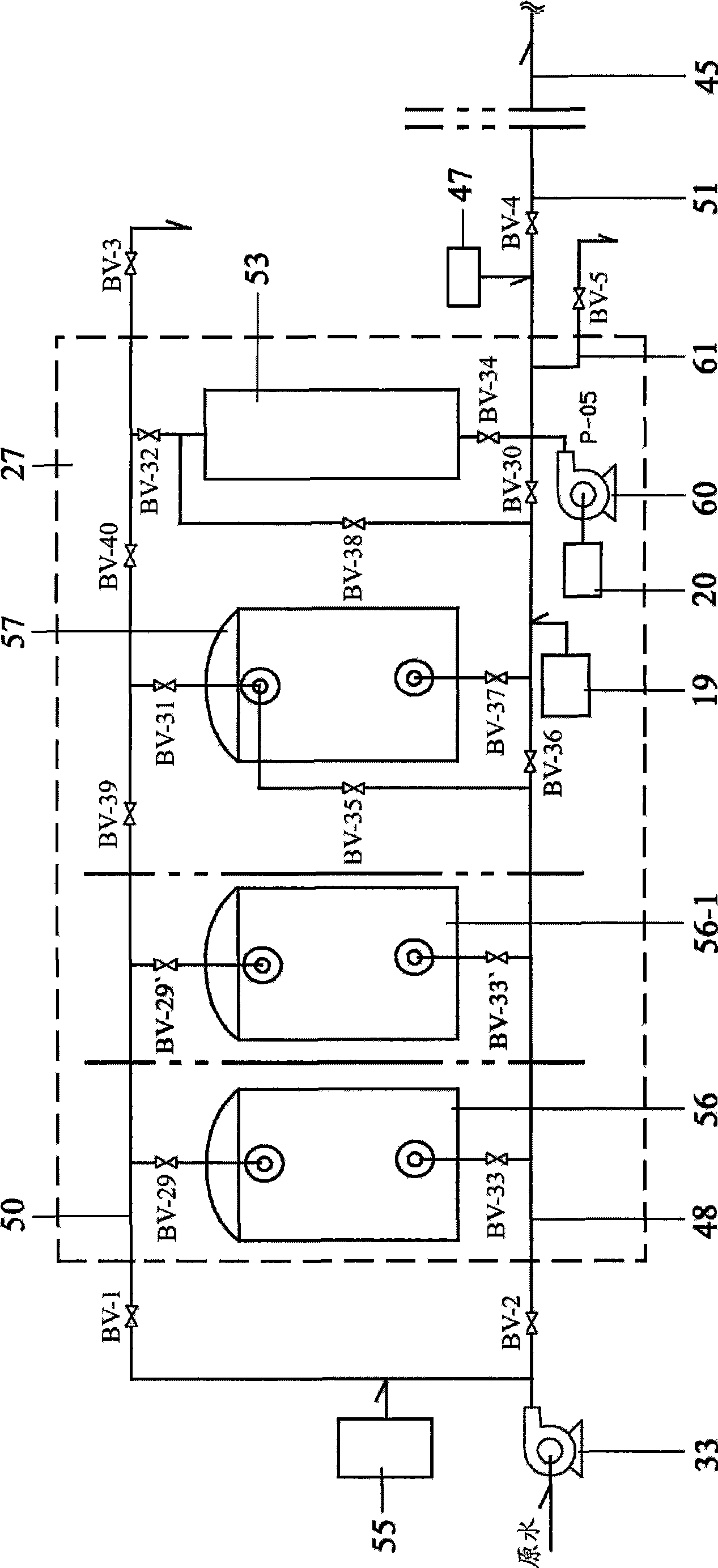

[0111] It consists of a pretreatment system (21), a reverse osmosis filtration system (22), a blending system (23), a cleaning system (24), a soaking maintenance system (25) and a finished product accumulation system (26). The pretreatment system (21) is It consists of a water diversion pump (33), a pretreatment water inlet pipeline (50), a backwash pipeline (48), a pretreatment water outlet pipeline (51) and a pretreatment filter facility (27). The input port of the water diversion pump (33) It is connected with the raw water and introduced into the raw water body by the water diversion pump (33), and the output port of the water diversion pump (33) is connected with the pretreatment water inlet pipeline (50) and the backwash pipeline (48).

[0112] The raw water body introduced by the water diversion pump (33) is directly used for filtering water or for backwashing pretreatment filter facilities (27). Pretreatment filter facility (27) is set in series on road (48), and pretr...

Embodiment 2

[0122] One end of the distribution conversion pipeline (45) is connected with the ball valve BV-4 of the pretreatment outlet pipeline (53), and the other end of the distribution conversion pipeline (45) is connected with the reverse osmosis filtration system (22), the blending system ( 23), the cleaning system (24) is connected with the immersion maintenance system (25), the other end of the distribution conversion pipeline (45) is connected with the high-pressure water pump (34) of the reverse osmosis filtration system (22), and the distribution conversion pipeline Set ball valve BV-18, security filter C-1, ball valve BV-6, check valve CV-1, ball valve BV-14 and ball valve BV-15 on (45), and set ball valve BV before security filter C-1 -18 is divided into two routes, one route is connected with the buffer water storage tank water inlet (8) of the buffer water storage tank (30) of the blending system (23) by setting the pipeline of the ball valve BV-18, and setting the one-way ...

Embodiment 3

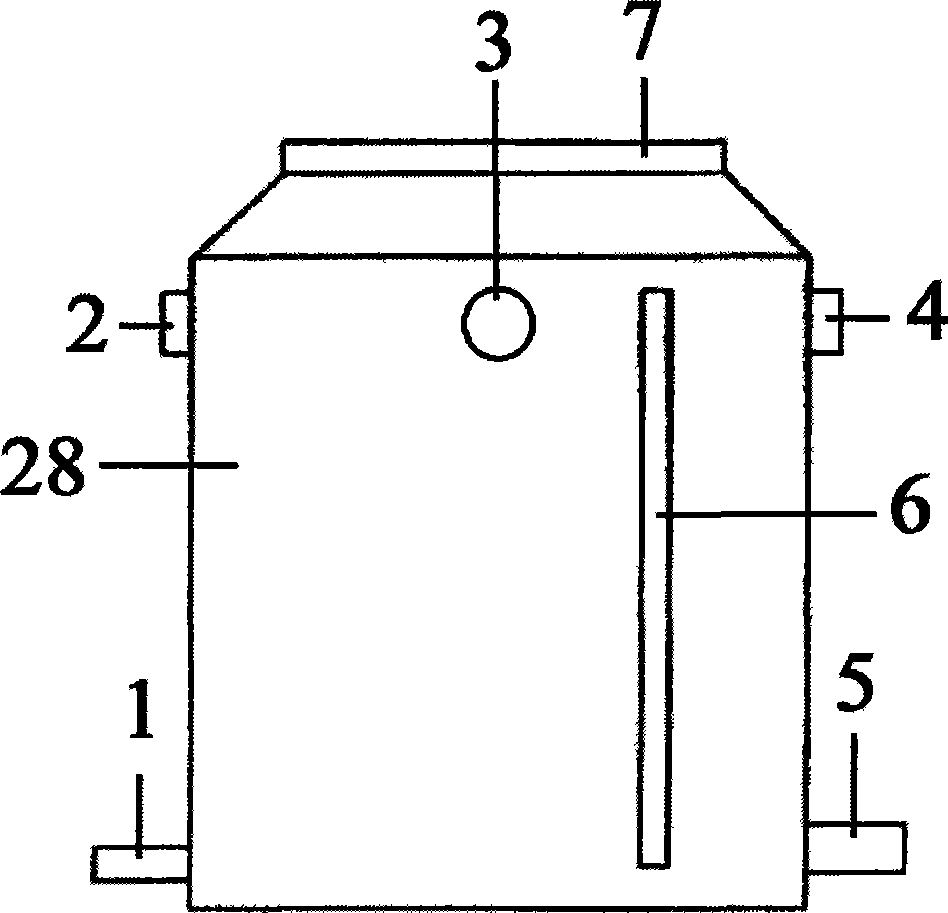

[0129] The blending system (23) comprises a buffer water storage tank (30), a blending circulation pump (36) and a blending pipeline (41), and the buffer water storage tank water inlet (8) of the buffer water storage tank (30) of the blending system (23) ) is connected with the ball valve BV-18 of the distribution conversion pipeline (45), and the pretreated water diverts into the buffer water storage tank (30). The water inlet (8) of the water storage tank, the water inlet (8) of the buffer water storage tank are connected with the ball valve BV-18, the water outlet (9) of the buffer water storage tank and the outlet (10) of the buffer water storage tank are arranged at the lower part, and the buffer water storage tank The outlet of the water tank (9) is connected to the input end of the blending circulation pump (36) through the ball valve BV-20, and the side of the buffer water storage tank (30) is provided with a buffer water storage tank level controller (11), and The liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com