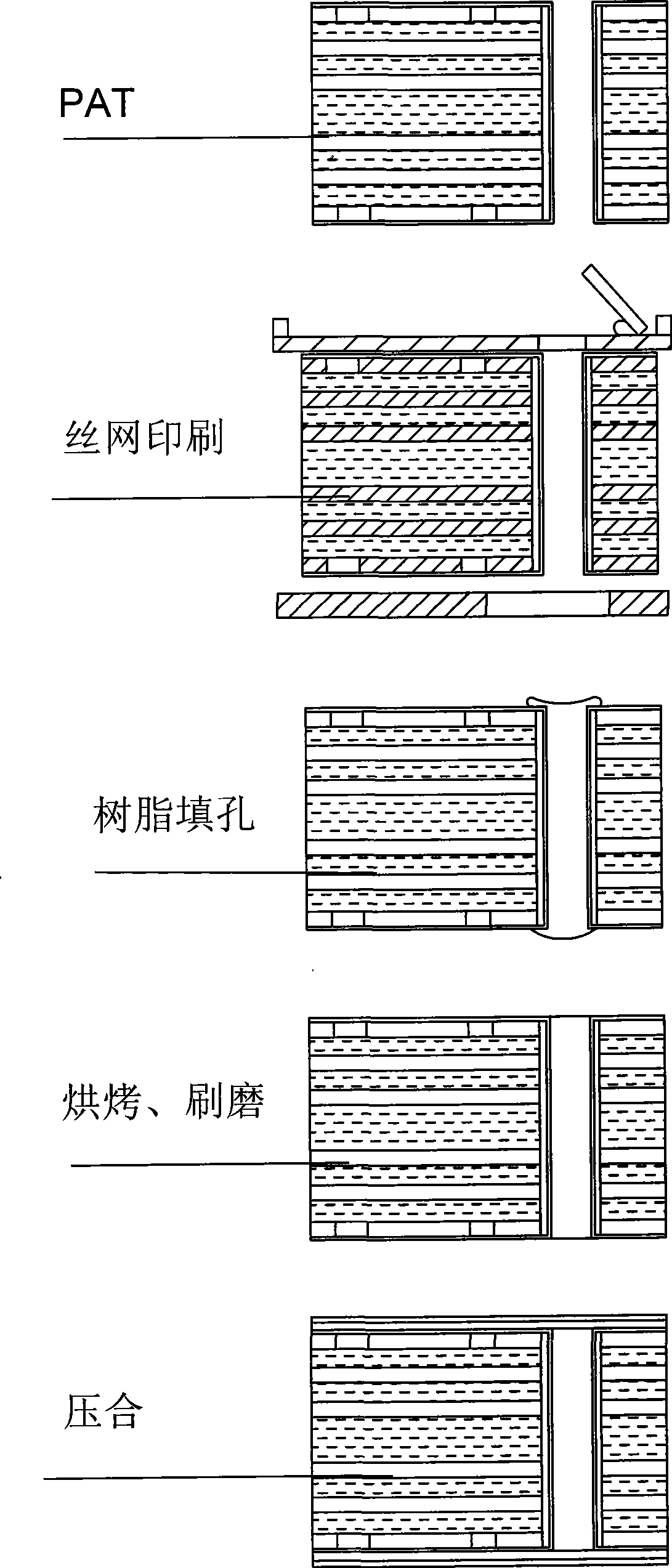

Process for blind hole, buried hole, and filled hole of multi-layered high density interconnected printed circuit board

A high-density interconnection and printed circuit board technology, which is applied in the direction of multi-layer circuit manufacturing and electrical connection formation of printed components, can solve the problems of many process steps, improve production efficiency, save production process, and shorten production time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] specific implementation plan

[0030] The present invention will be further described below in conjunction with embodiment:

[0031] refer to figure 2 As shown, the blind hole, buried hole, and hole filling process of multilayer high-density interconnection printed circuit boards, (1) firstly use liquid medicine to generate uniform reddish brown or black oxidation on the copper surface of printed circuit boards with drilled holes. layer, so that the roughness of the oxide layer can be formed so that it can be tightly combined with the bonding sheet and can avoid the cuprous chloride formed by the high-temperature reaction between the surface of the raw copper and the pressing, which affects the reliability of the product. (2) followed by the traditional screen For printing, first drill the holes to be filled on the aluminum sheet, and then put the perforated aluminum sheet into the wooden screen frame instead of the traditional silk cloth screen, and use the aluminum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com