Method for preparing titanic chloride by half cycle fluidization

A titanium tetrachloride, semi-circulation technology, applied in the direction of titanium halide, fluidized bed furnace, lighting and heating equipment, etc., to achieve the effect of high coke concentration, sufficient contact, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

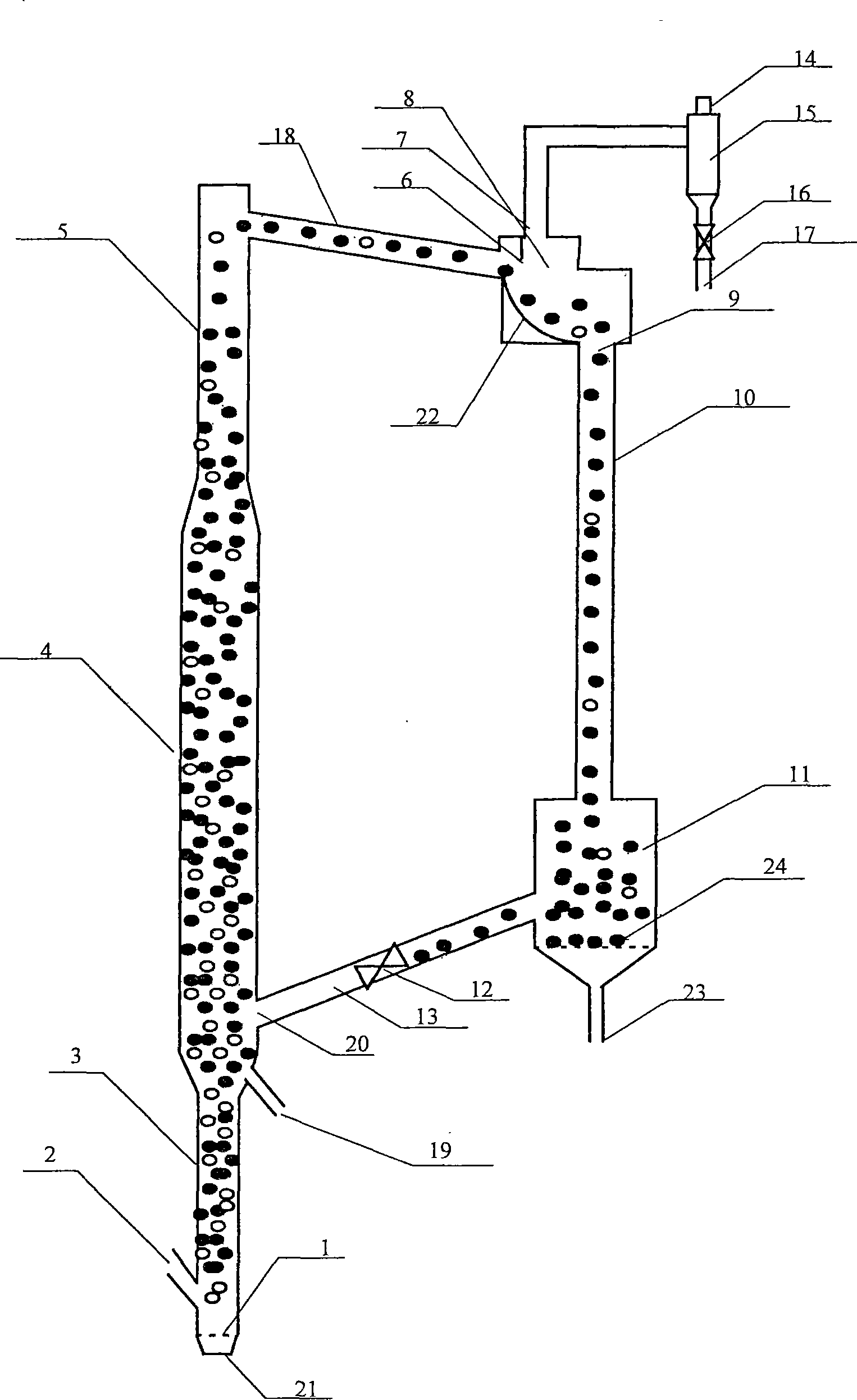

[0026] Such as figure 1 Shown, the concrete steps of the method for preparing titanium tetrachloride by a kind of semicirculation fluidization are as follows:

[0027] (1) Raw material preheating

[0028] Low-grade high-titanium slag and coke are used as solid raw materials, and chlorine and nitrogen are used as gas raw materials. For solid raw materials, the average diameter of high titanium slag particles: the average diameter ratio of coke particles is 1:0.9, and the mass ratio of high titanium slag:coke is 1:1, and the high titanium slag particles and coke particles are mixed After uniformity, the solid mixture is heated by an electric heater until the temperature of the solid mixture is 500°C. At the same time, nitrogen and chlorine are mixed, wherein the molar percentage of chlorine is 70%, and the molar percentage of nitrogen is 30%, and then the mixed gas is heated through a heat exchanger until the temperature of the gas mixture is 450°C.

[0029] (2) Chlorination ...

Embodiment 2

[0038] A kind of semicirculation fluidization prepares the concrete steps of the method for titanium tetrachloride as follows:

[0039] (1) Raw material preheating

[0040] With embodiment 1. The characteristics are: the mass ratio of high titanium slag:coke is 1:0.3, the average diameter ratio of high titanium slag particles:coke particles is 1:1.2, the molar percentage of chlorine is 100%, and the molar percentage of nitrogen is 0 %.

[0041] (2) Chlorination reaction

[0042] With embodiment 1. The feature is that the linear velocity of the gas in the gas-solid premixing section 3 is 5.5m / s, and the linear velocity of the gas in the fluidized reactor 4 is 3.6m / s.

[0043] (3) cooling

[0044] With embodiment 1.

[0045] (4) Gas-solid separation

[0046] With embodiment 1.

[0047] The conversion rate and yield of high-titanium slag were determined by experiments, and the TiO 2 The conversion rate reaches 95%, and the titanium yield reaches 92%.

Embodiment 3

[0049] A kind of semicirculation fluidization prepares the concrete steps of the method for titanium tetrachloride as follows:

[0050] (1) Raw material preheating

[0051] With embodiment 1. The characteristics are: the mass ratio of high titanium slag: coke is 1:1.5, the average diameter ratio of high titanium slag particles: coke particles is 1:0.8, the molar percentage of chlorine gas is 50%, and the molar percentage of nitrogen gas is 50% %, heated to a solid mixture temperature of 400 ° C. Heat until the temperature of the gas mixture is 300°C.

[0052] (2) Chlorination reaction

[0053] With embodiment 1. The characteristics are: the linear velocity of the gas in the gas-solid premixing section 3 is 4m / s, the linear velocity of the gas in the fluidized reactor 4 is 2.8m / s, and the reaction temperature is 900°C.

[0054] (3) cooling

[0055] With embodiment 1. The characteristic is that the temperature at the outlet of the cooling section 5 is 450°C.

[0056] (4)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com