Table tennis bat rubber cutting machine

A table tennis racket and cutting machine technology, applied in metal processing and other directions, can solve the problems of poor cutting effect, low efficiency, uneven rubber edge, etc., and achieve the effect of fast speed, high efficiency and convenient portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

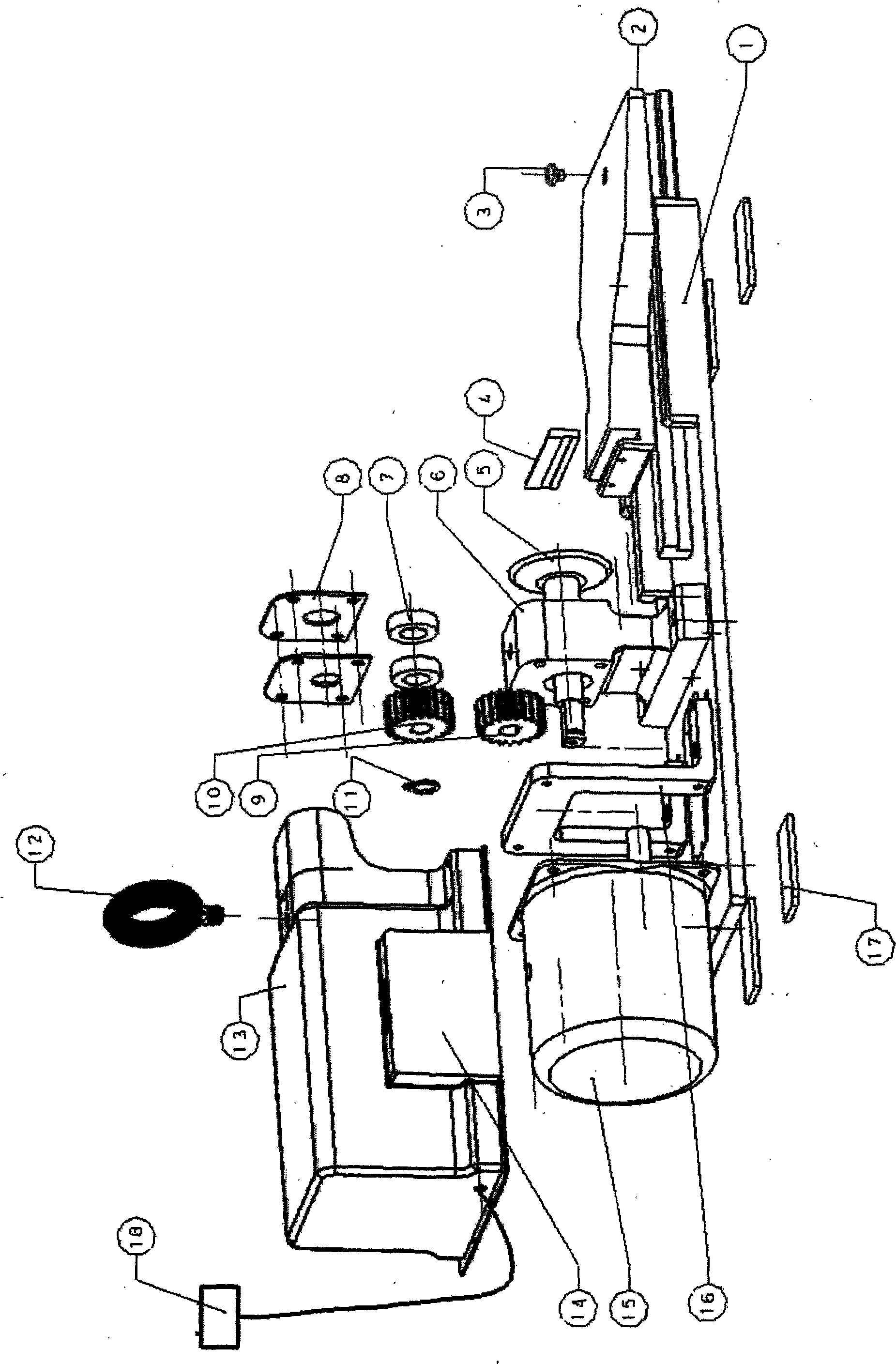

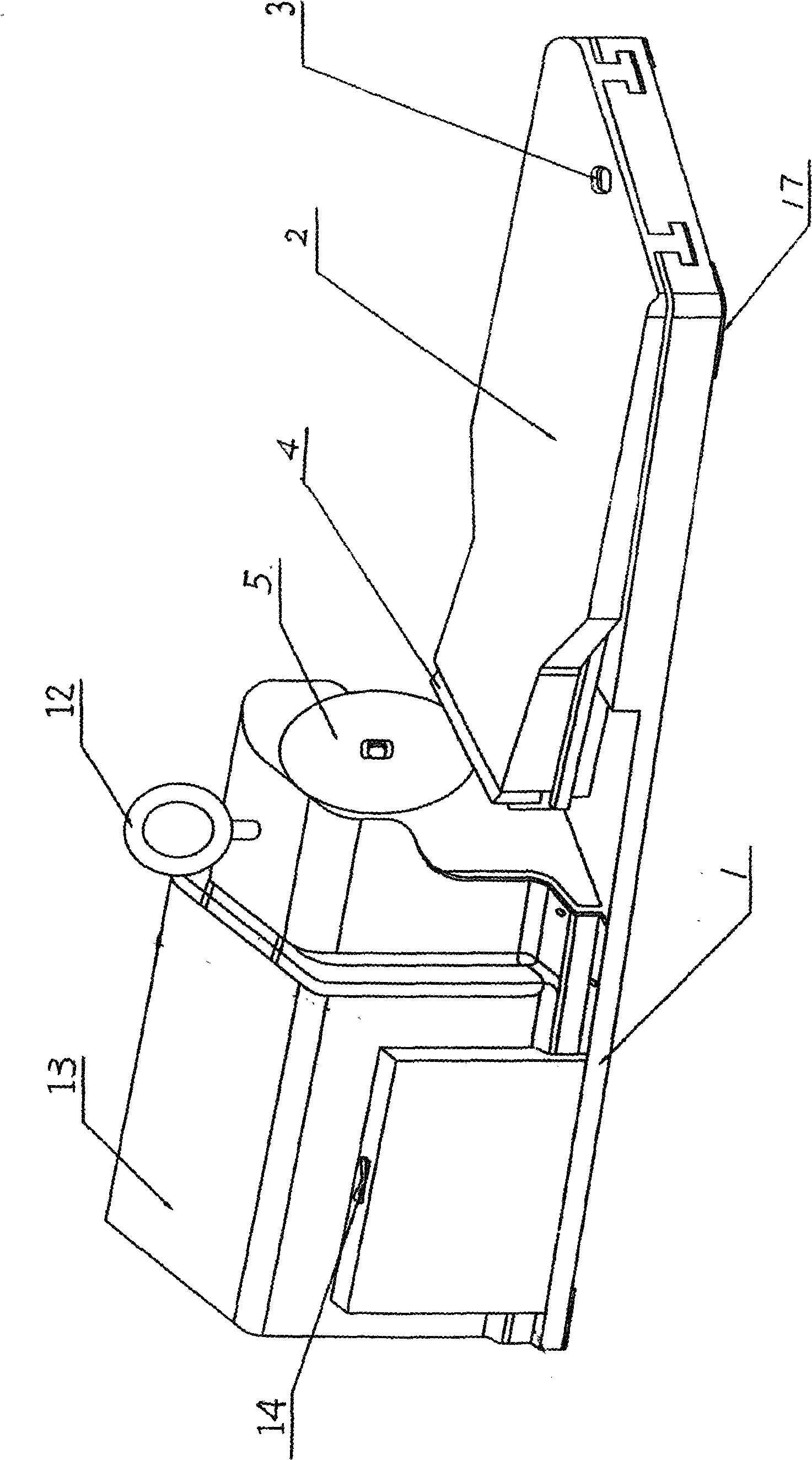

[0021] see figure 1 , figure 2 : This table tennis racket rubber cutting machine includes a driver 15, a cutting part and a platform 2 installed on a base plate 1.

[0022] The driver 15 generally adopts a motor, preferably a low-speed synchronous motor.

[0023] Cutting part is the shearing pair that rotary blade 5 and fixed blade 4 are formed, and the cutting edge angle of rotary blade is 10~65 °, preferably about 30 °. The rotary blade 5 has a rotating shaft, and the rotating shaft is supported on a bearing seat 6 through a bearing 7 , and the bearing seat 6 has an end cover 8 . The bearing seat 6 is fixed on the bottom plate 1, and in order to ensure accurate positioning, a positioning pin is provided at the junction of the bearing seat 6 and the bottom plate 1. The shaft end of the rotating blade 5 is connected with a driving motor 15 . 1 shows amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com